High-efficiency mowing and gathering machine

A high-efficiency, mowing technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., to improve the efficiency of forage collection, save power and cost, and have a strong pertinence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

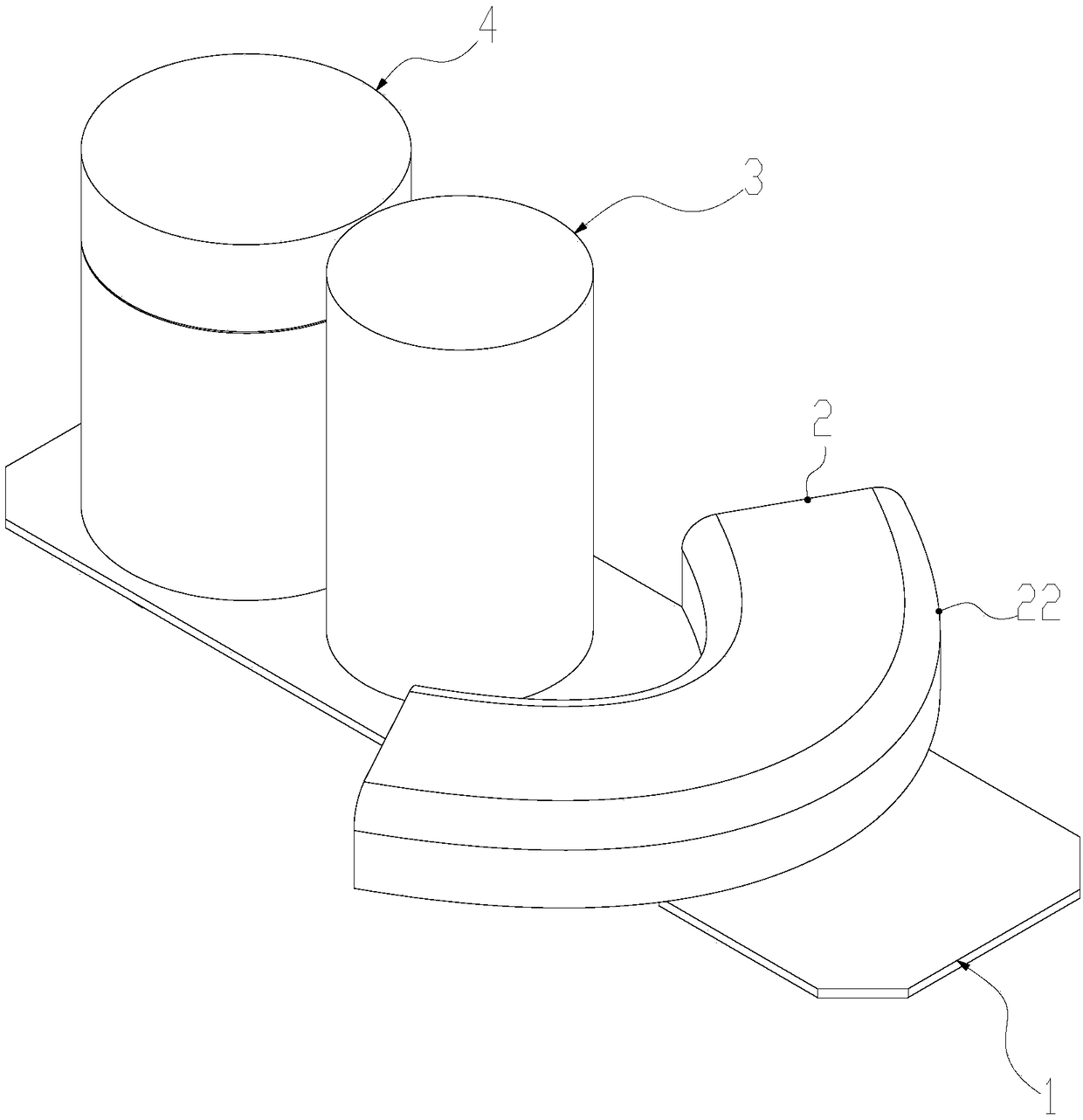

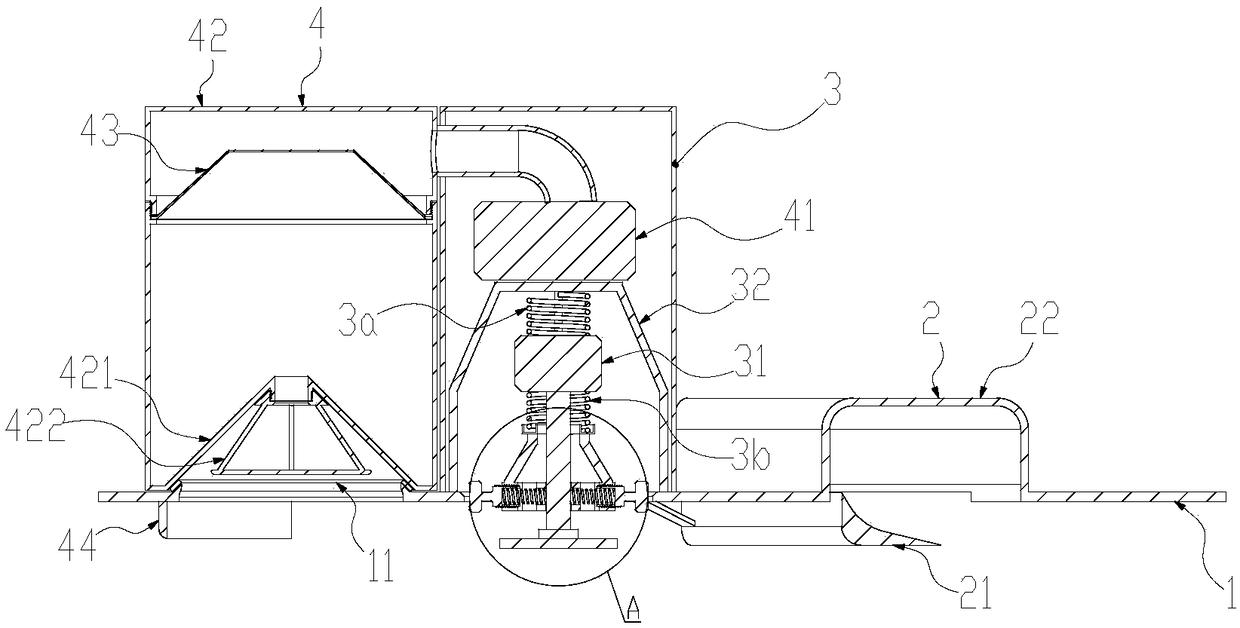

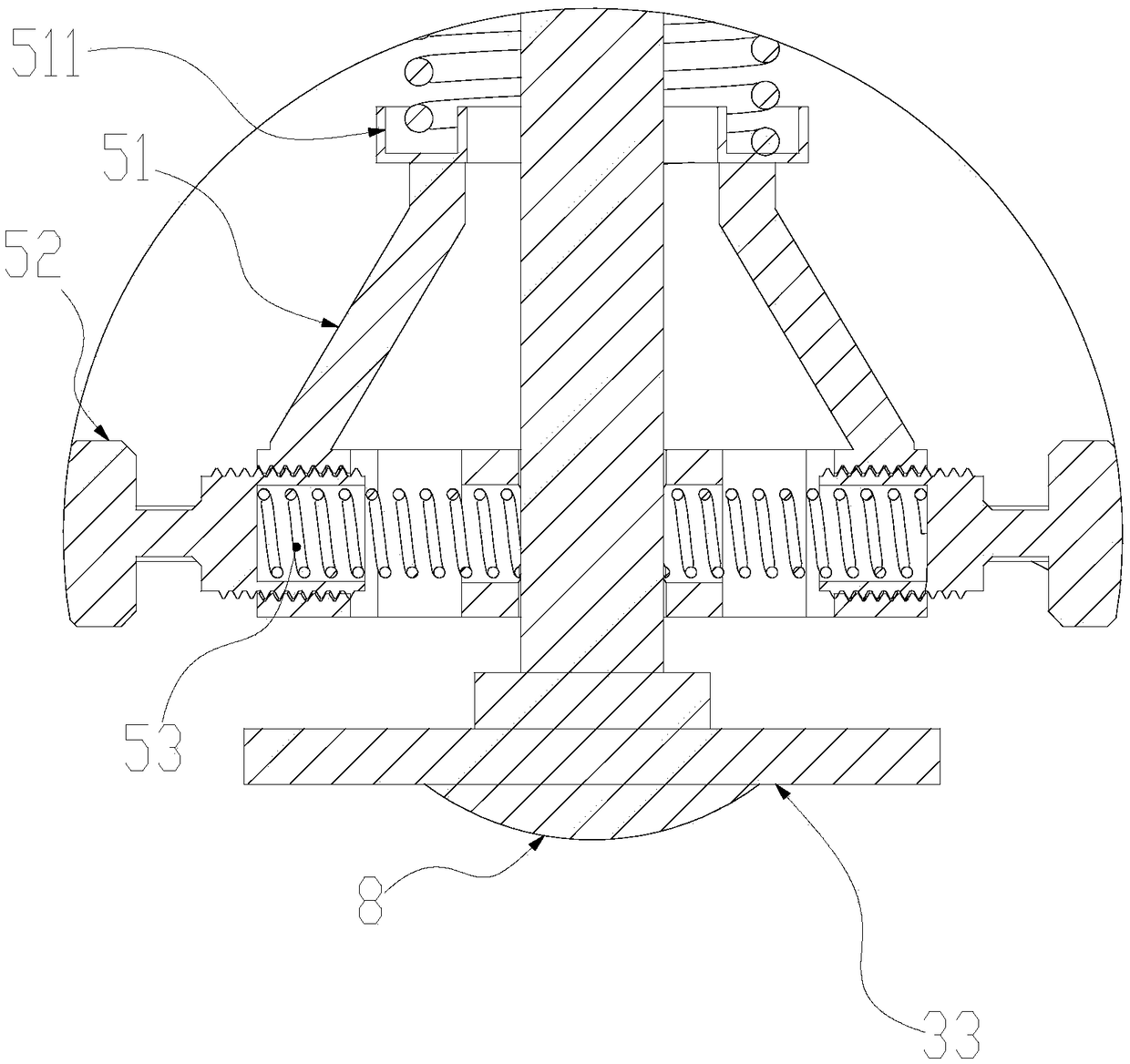

[0038] Such as Figures 1 to 5 The shown high-efficiency machine for mowing and harvesting includes a base 1 with wheels, a front impurity removal device 2 installed on the base 1, a middle mowing device 3 and a rear receiving device 4. The mowing device 3 includes a motor 31 , a motor mount 32 and a mowing blade 33 . The above-mentioned motor 31 is installed on a motor mounting frame 32 , and the motor mounting frame 32 is fixed on the base 1 . The base 1 is provided with a through hole, and the motor 31 is elastically mounted on the motor mount 32 through a spring, and the output end of the motor 1 passes through the through hole of the base to connect to the mowing blade 33 . The mowing blades 33 include a rotating member shaft-connected to the output end of the motor 31 and a plurality of sets of blades fixedly inserted on the rotating member. A hemispherical convex portion 8 is arranged below the above-mentioned rotating member, and the hemispherical convex portion 8 ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com