Method for researching thermal characteristics of static pressure rotating worktable under extreme conditions

A technology of rotary table and table, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of large temperature increase of oil film calorific value, uneven deformation of table, thermal deformation of table, etc. Achieve the effect of improved operation accuracy and stability, stable hydrostatic rotary table, and improved safe operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] It can be achieved through the following technical solutions:

[0012] The calculation of the convective coefficient of the workbench can be divided into two parts: the upper surface and the side, that is, the calculation of the upper surface convective heat transfer coefficient can be compared to the fluid flowing through the horizontal plate, and the calculation of the side convective heat transfer coefficient can be compared to the fluid passing through the horizontal direction. Vertical flat wall.

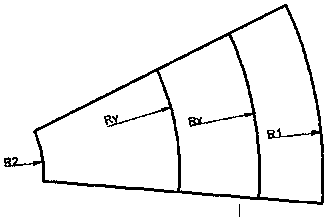

[0013] Because the radius of the rotary table is relatively large, the surface linear velocity at the outer edge of the rotary table and the center of rotation is very different, so the flow state of the air near the surface of the rotary table is also different, so the convection between the rotary table and the air The difference in heat transfer intensity is relatively large. In order to obtain simulation results closer to the actual working conditions, the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com