Bubble reducing device for hydraulic oil for CNG hydraulic substation

A technology of hydraulic sub-station and hydraulic oil, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve the problems of bubble burst, serious noise pollution, high pressure pump damage, etc., and achieve the effect of defoaming The effect of improving operation efficiency and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

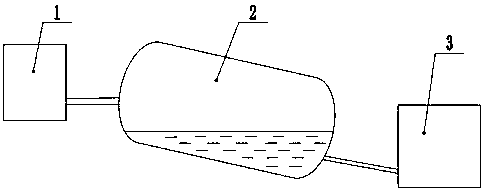

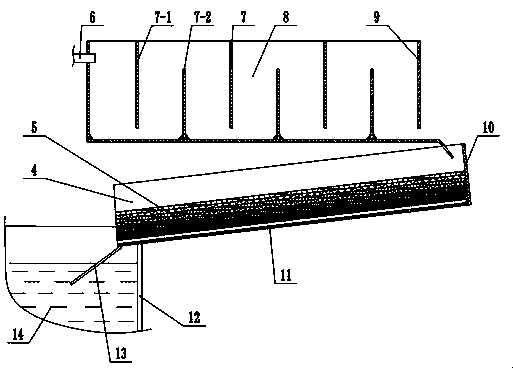

[0014] as attached figure 2 As shown, the air bubble reduction device of the present invention is added between the fuel tank 12 of the CNG hydraulic filling substation and the oil return port 6. The air bubble reduction device includes a surge device 8 and a slide device 4, and the hydraulic oil 14 is from the oil return port. 6 flows into the surge device 8, then flows into the slide device 4, and flows into the fuel tank through the guide plate 13.

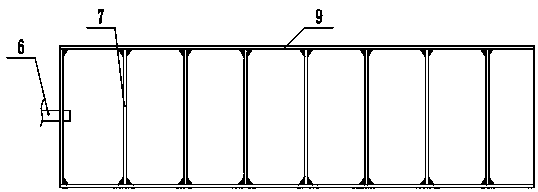

[0015] The oil inlet of the surge device 8 is the oil return port 6 of the fuel tank, and the surrounding four surge device baffles 9 and the bottom plate weld the device into a box shape, and the attached image 3 It is a top view of the surge device, and a plurality of partitions 7 are fixedly welded inside the surge device 8. The partitions 7 are divided into an upper partition 7-1 and a lower partition 7-2, and the upper partition 7-1 and the bottom plate Leave a distance to keep the lower part of the upper partition 7-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com