Non-constant-temperature type heated electronic smoking set consistency detecting method and system

A detection method, a non-constant temperature technology, applied in the field of consistency detection of non-constant temperature heating electronic cigarettes, to achieve the effects of sensitive temperature detection, intuitive detection method, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

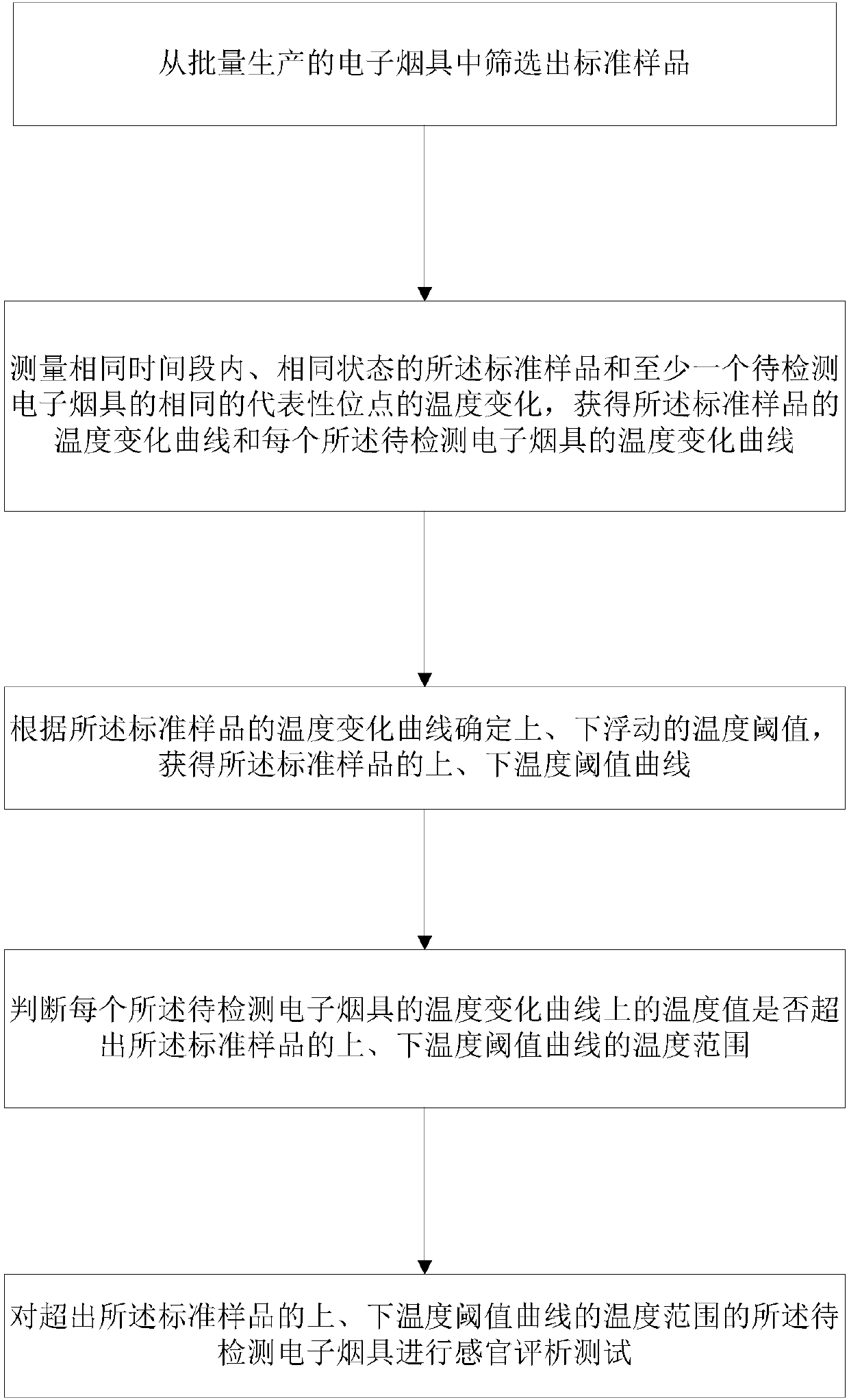

[0023] Such as figure 1 As shown, the present invention provides a non-constant temperature heating electronic cigarette consistency detection method, including the following steps:

[0024] 1. Screen out standard samples from mass-produced electronic cigarette sets;

[0025] 2. Measure the temperature change of the standard sample and the same representative point of at least one electronic cigarette to be tested in the same period of time and in the same state, and obtain the temperature change curve of the standard sample and each of the electronic cigarettes to be tested. The temperature change curve of the smoking appliance;

[0026] The typical location is the side wall of the heating chamber of the electronic cigarette appliance or the bottom of the heating chamber of the electronic cigarette appliance. Measuring the temperature of the same representative point of the standard sample and at least one electronic cigarette article to be tested every 0.1-2 seconds within...

Embodiment 2

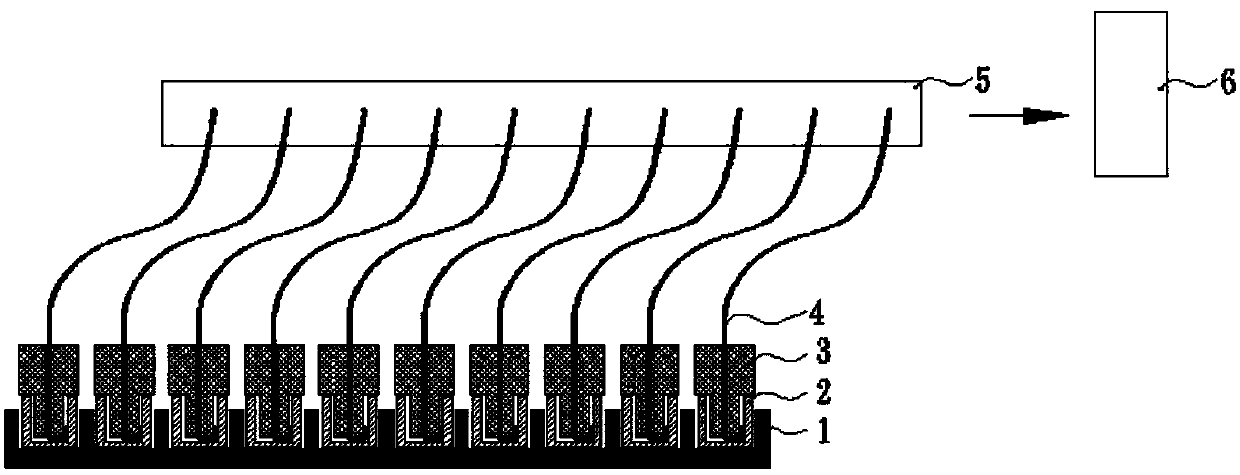

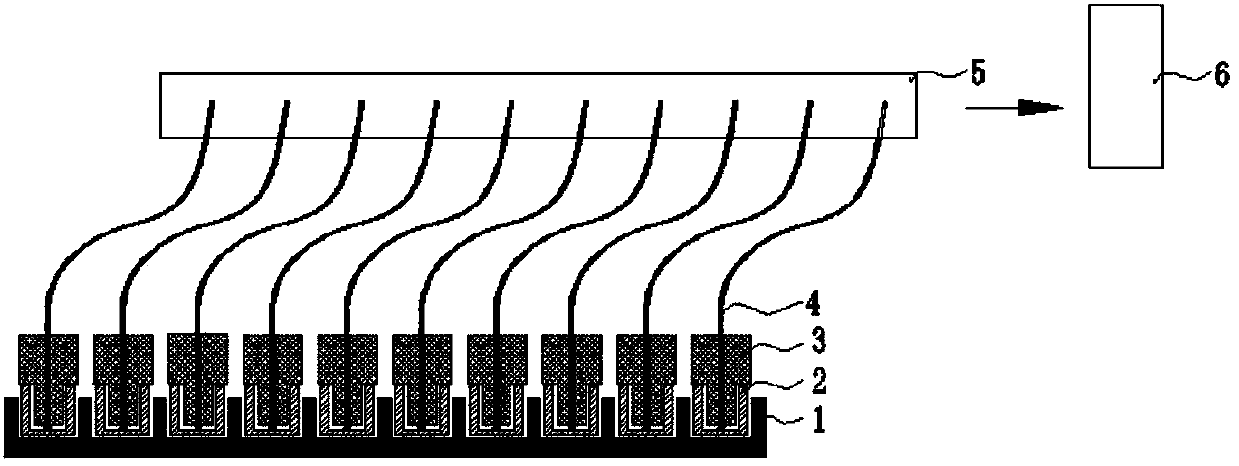

[0051] Such as figure 2As shown, the present invention also provides a non-constant temperature heating electronic cigarette appliance consistency detection system, including a product tray 1, a fixture 3, a temperature sensing line 4, a data recorder 5, and a control center 6. The product tray 1 is used to carry and fix The standard sample and the electronic cigarette device 2 to be tested; the clamp 3 is used to fix the temperature sensing line 4 on the standard sample and the electronic cigarette device 2 to be tested; one end of the temperature sensing line 4 is fixed by the clamp 3 on the representative of the standard sample and the electronic cigarette device 2 to be tested The other end is connected to the data recorder 5; the data recorder 5 is used to record the temperature of the representative site, and is connected to the temperature sensing line 4 and the control center 6 respectively, and the control center 6 is used to control the operation of the system.

[0...

Embodiment 3

[0056] Using the method provided by the present invention to carry out the consistency test on mass-produced electronic cigarette sets, specifically includes the following steps:

[0057] 1. Take 1 pre-screened standard sample and 9 other electronic cigarette sets to be tested (the products are all fully charged and in good condition), fix these 10 products on the sample tray, connect the thermocouple connection wire or thermal resistance The wire passes through the silicone fixture, so that the thermocouple probe is attached to the side wall of the heating chamber;

[0058] 2. Open the control center of the data logger and the computer (multi-channel temperature data logger produced by Amber Precision Instrument Co., Ltd. collects temperature);

[0059] 3. Start the control center and open these 10 products at the same time;

[0060] 4. Data collection, observe the temperature curve change, measure the temperature of the standard sample every 0.1 or 1 second or 2 seconds and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com