A three-dimensional structure detection method of optical fiber splicing point based on digital holographic tomography

A technology of digital holography and three-dimensional structure, which is applied in the testing of machine/structural components, optical instrument testing, measuring devices, etc., to achieve the effect of simple algorithm operation, simple calculation process and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

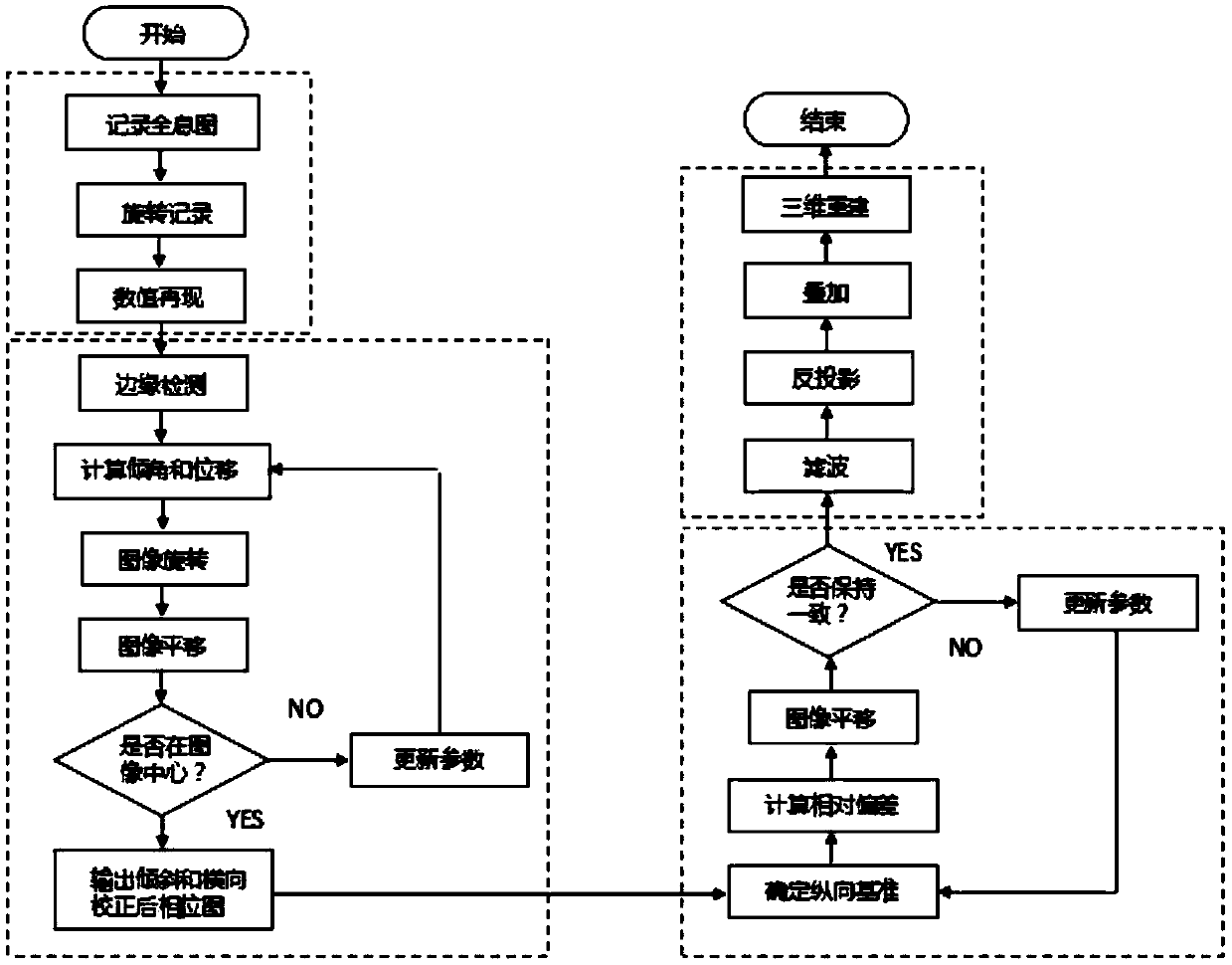

[0042]The present invention is a three-dimensional structure detection method of optical fiber fusion points based on digital holographic tomography. Firstly, the holograms of the optical fiber fusion points at various angles are obtained through the off-axis digital holographic optical path. The axial error is corrected by selecting different reproduction distances to obtain accurate phase images of the optical fiber at various angles; then the lateral error, longitudinal error, and image tilt correction are performed on the phase images at each angle, and finally the optical fiber fusion splice is obtained by using the tomographic filter back projection algorithm The three-dimensional structure of a point includes the following steps:

[0043] In the first step, the off-axis digital holography system is used to record the holograms of the spliced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com