Ultrasonic impact treatment method for reducing residual stress of titanium alloy thin plate welded structure

An ultrasonic impact and welding structure technology, applied in the field of metal processing, can solve the problems of coarse grains, size and structure limitation, metal oxidation in the weld area, and achieve the effects of large energy consumption, consistency guarantee, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Ultrasonic impact treatment was performed on electron beam welded structures of 3 mm thick titanium alloy sheets. Include the following steps:

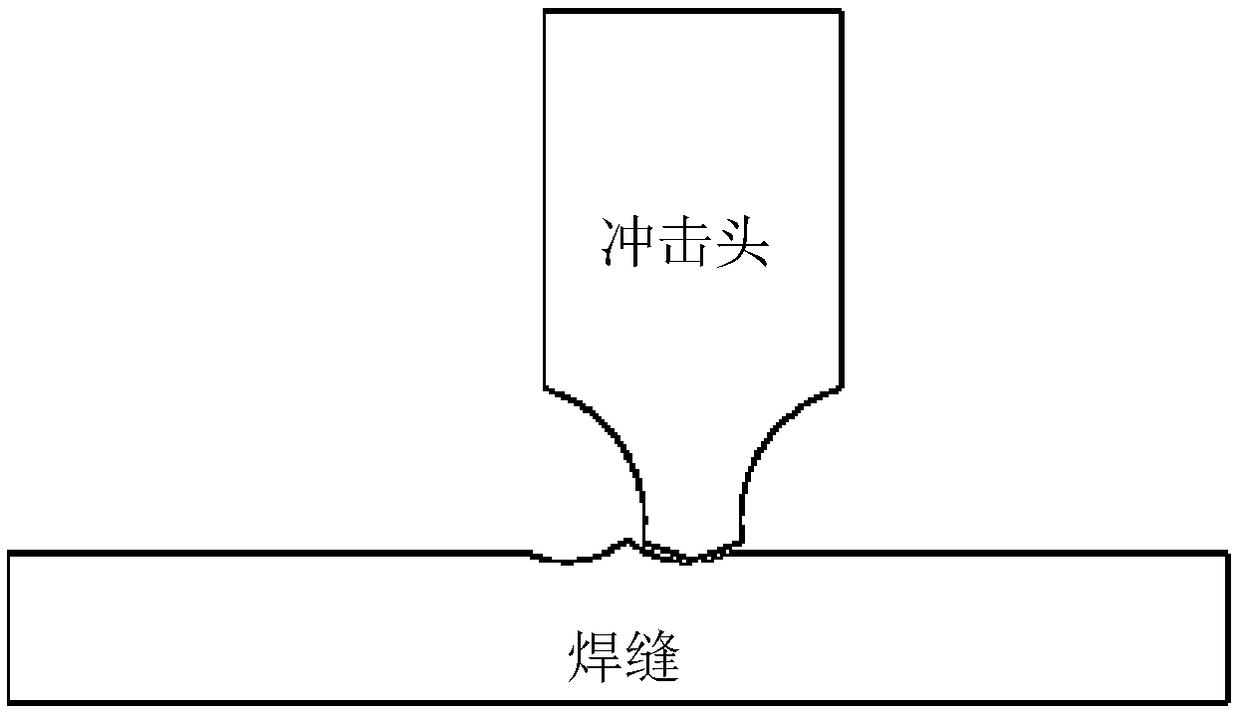

[0025] Step 1: Selection of impact head: According to the welding method of titanium alloy sheet, the shape of the impact head is closely related to the shape of the welded joint. In vacuum electron beam welding, the weld width is 5mm narrower, so a flat impact of 2mm is selected. head;

[0026] Step 2: Optimization of ultrasonic impact treatment process parameters: According to the optimized treatment process of titanium alloy thin plate electron beam welding welding components, the impact method is welding toe impact process, the impact speed is 200mm / min, the width is 4mm, the impact angle is 90°, the impact The number of times is 3 times, one-sided impact;

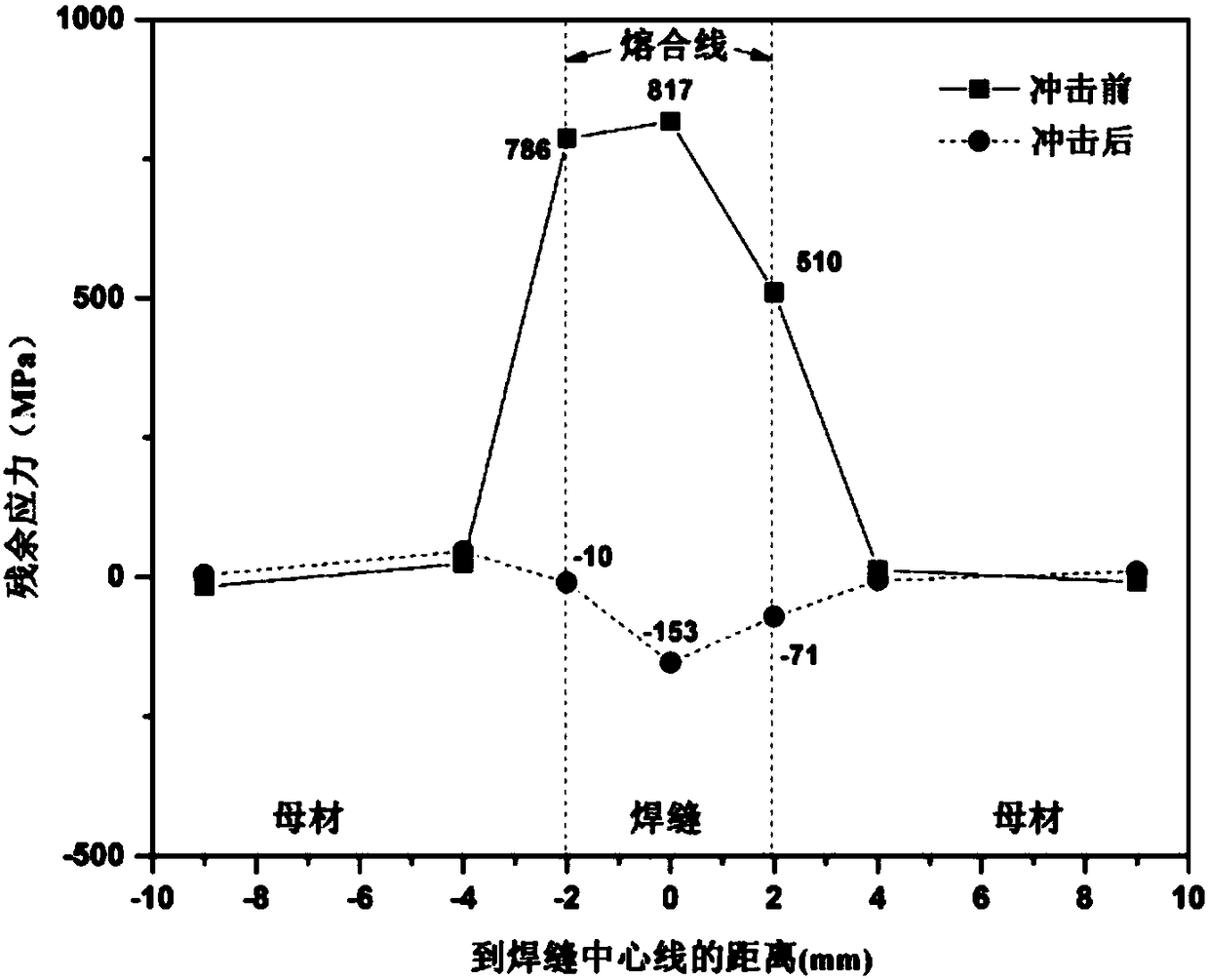

[0027] Effect evaluation: use the conventional stress test method to test the stress before and after the ultrasonic impact treatment of the electron beam welded stru...

Embodiment 2

[0029] Electron beam welded structures of 1 mm thick titanium alloy sheets were subjected to ultrasonic shock treatment. Include the following steps:

[0030] The first step: selection of the impact head: according to the electron beam welding structure of the titanium alloy thin plate, the weld width is 3mm, so a flat impact head of 2mm is selected;

[0031] Step 2: Ultrasonic impact treatment process parameter optimization: According to the optimized treatment process of titanium alloy thin plate electron beam welding welding components, the impact method is welding toe impact process, the impact speed is 150mm / min, the width is 4mm, the impact angle is 90°, the impact The number of times is 3 times, one-sided impact.

[0032] Effect evaluation: Use the conventional stress test method to test the stress before and after the ultrasonic impact treatment on the 1mm thick titanium alloy thin plate electron beam welding structure. The stress value at the welded joint before the ...

Embodiment 3

[0034] Electron beam welded structures of 1 mm thick titanium alloy sheets were subjected to ultrasonic shock treatment. Include the following steps:

[0035] The first step: selection of the impact head: according to the electron beam welding structure of the titanium alloy thin plate, the weld width is 6mm, so a flat impact head of 2.5mm is selected;

[0036] Step 2: Optimization of ultrasonic impact treatment process parameters: According to the optimized treatment process of titanium alloy thin plate electron beam welding welding components, the impact method is welding toe impact process, the impact speed is 200mm / min, the width is 4mm, the impact angle is 90°, the impact The number of times is 4 times, one-sided impact.

[0037] Effect evaluation: The conventional stress test method is used to test the stress before and after the ultrasonic impact treatment of the electron beam welded structure of the 1mm thick titanium alloy sheet. The peak stress in the center is 745...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress value | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com