Ga-doped inp quantum dots with core-shell structure and preparation method thereof

A quantum dot and shell structure technology is applied in the field of Ga-doped InP quantum dots and their preparation, which can solve the problems of increased defects, large half-peak width, defects between core-shell interfaces, etc., and achieves the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In order to obtain quantum dots with the above structure, the present invention also discloses a method for preparing Ga-doped InP quantum dots with a core-shell structure, comprising the following steps: 1) adding an indium precursor to a compound containing the first ligand In an organic solvent, heat to 180-260 ° C, add PH 3 , to obtain a mixed system with InP nanocrystalline nuclei; 2) adding the indium precursor and the gallium precursor to the organic solvent containing the second ligand, heating to dissolve, and obtaining a mixed precursor solution of indium and gallium; 3) adding Mix precursor solution and pH in step 2) 3 Add to the mixing system in step 1) in turn to form a Ga-doped InGaP nanocrystalline intermediate layer; 4) Add the precursor substances required for the shell layer of the synthetic quantum dot to obtain a Ga-doped InP quantum dot with a core-shell structure point; the composition of the Ga-doped InGaP nanocrystalline interlayer is In x Ga ...

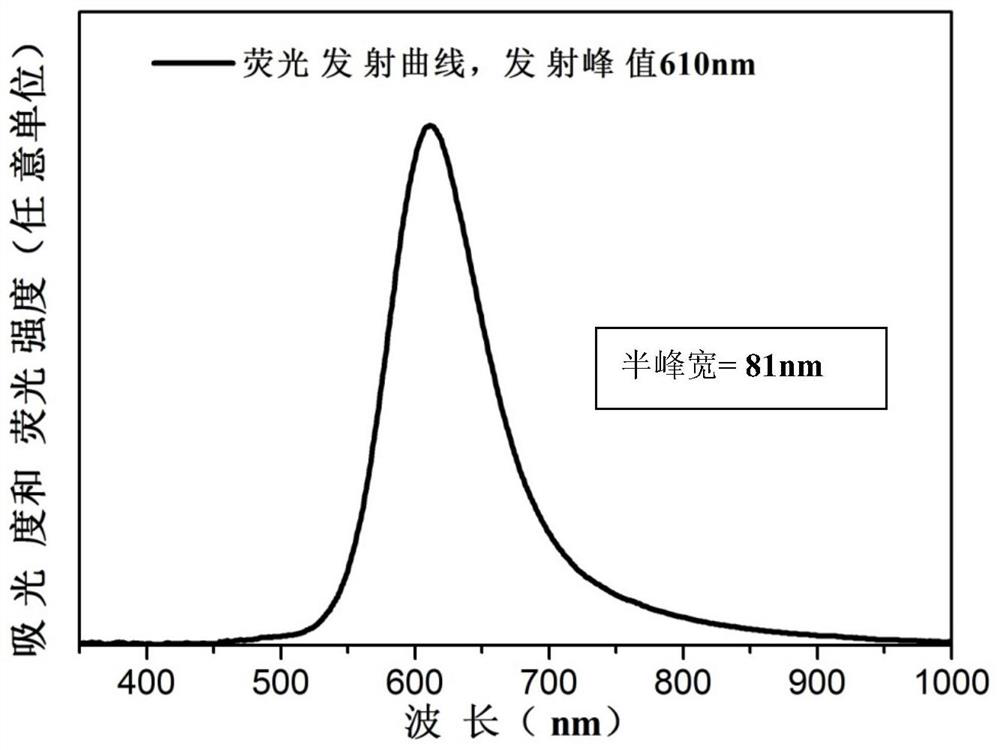

Embodiment 1

[0059] Preparation of Ga-doped InP quantum dot samples with core-shell structure 1

[0060] (1) Preparation of indium oleate (In-OA): add indium acetate, oleic acid and 1-octadecene into a three-necked flask, heat until dissolved, and obtain a clear and transparent solution of In-OA with a concentration of 0.1M;

[0061] (2) Preparation of gallium oleate (Ga-OA): add gallium chloride, oleic acid and 1-octadecene into a three-necked flask, heat until dissolved, and obtain a clear and transparent solution of Ga-OA with a concentration of 0.1M;

[0062] (3) Preparation of zinc oleate (Zn-OA): add zinc acetate, oleic acid and 1-octadecene into a three-necked flask, heat until dissolved, and obtain a clear and transparent solution of Zn-OA with a concentration of 0.5M;

[0063] (4) Preparation of indium oleate and gallium oleate mixture (In-OA+Ga-OA): Mix the prepared In-OA and Ga-OA in (1) and (2) in equal proportions, heat and stir until well mixed;

[0064] (5) Preparation of ...

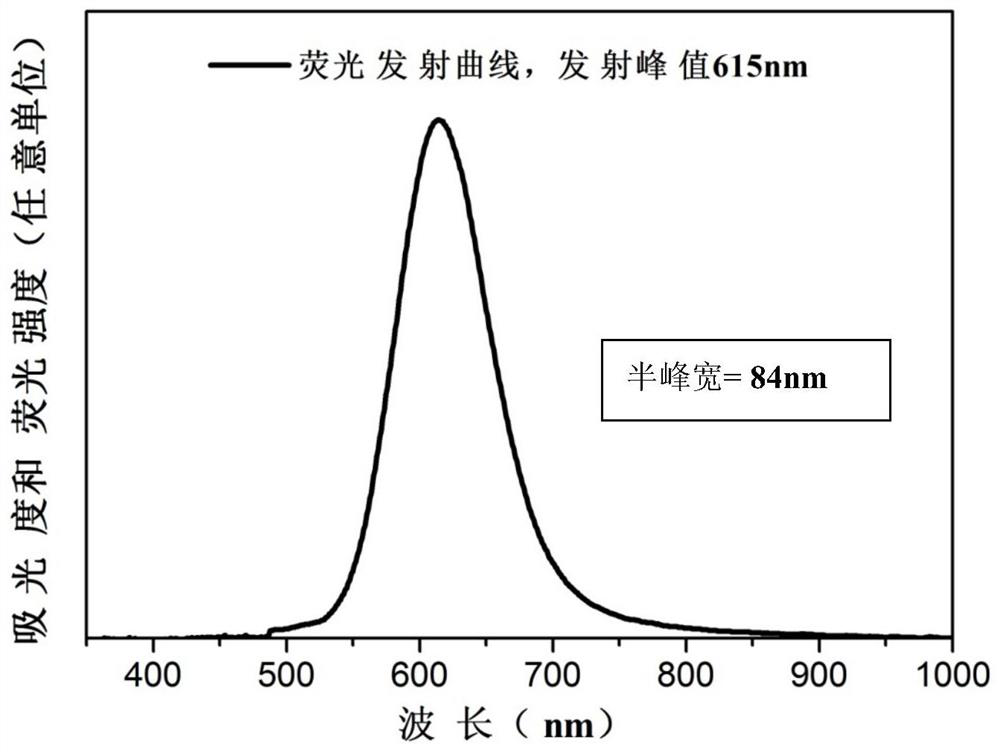

Embodiment 2

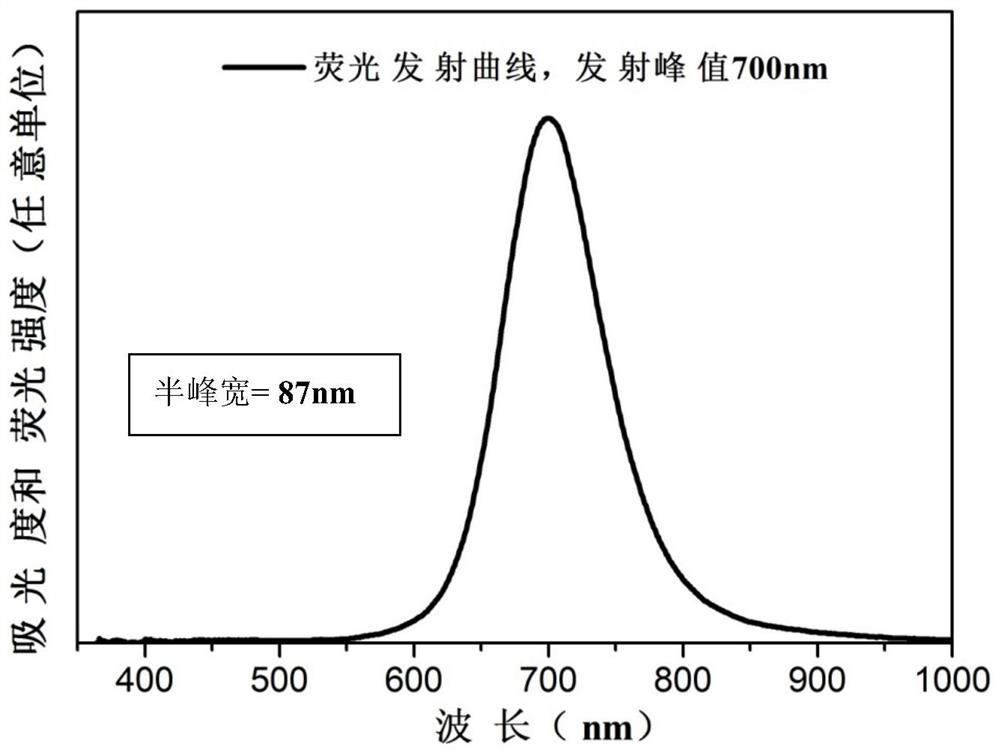

[0072] Fabrication of Ga-doped InP quantum dot samples with core-shell structure 3

[0073] Add In(OAc) to the three-neck flask 3 (300mg), Zn(OAc) 2 (100mg), myristic acid (700mg) and 1-octadecene (10mL), heated to dissolve, and passed into N 2 , keep the reaction for 120min to obtain a clear and transparent solution. Continue to heat to 230°C, pass a certain amount of pH 3 gas, reacted for 30min, added dropwise 1mL of the In-OA+Ga-OA solution obtained in step (4) of Example 1 to the solution, reacted for 30min, and then slowly introduced a certain amount of pH 3 Gas, react for 30min. Next, 2 mL of the In-OA+Ga-OA solution obtained in step (4) in Example 1 was added dropwise to the solution for the second time, reacted for 30 minutes, and then a certain amount of pH was slowly introduced into the solution. 3 Gas, react for 30min. For the third time, 3 mL of the In-OA+Ga-OA solution obtained in step (4) in Example 1 was added dropwise to the solution, reacted for 30 min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com