Tool for reflow welding of cavity printed board

A technology of reflow soldering and printed boards, which is applied in the fields of printed circuit manufacturing, circuit board tool positioning, printed circuit assembly of electrical components, etc. Uncontrollable environment and other issues, achieve good consistency, avoid displacement risk, and ensure welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

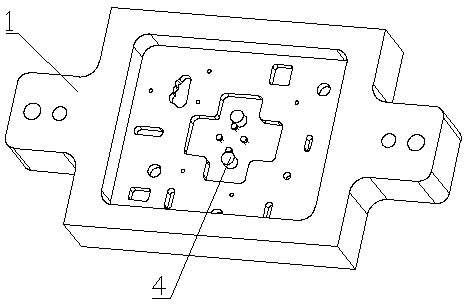

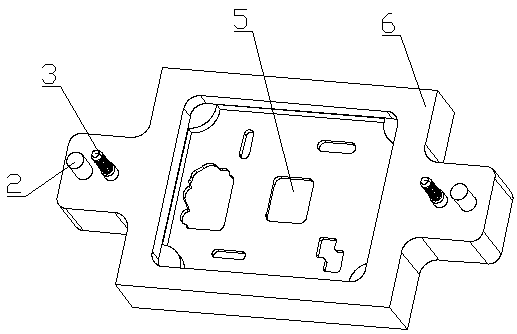

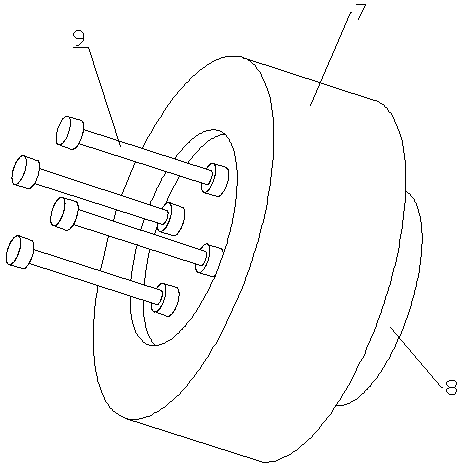

[0020] Such as Figure 1~Figure 3 As shown, a tooling for reflow soldering of cavity printed boards includes a lower cover 6 and an upper cover 1 of similar size, and the left and right sides of the lower cover 6 and the upper cover 1 are provided with corresponding left ears. and the right ear, the lower cover plate 6 and the upper cover plate 1 are provided with welding cavities, the lower cover plate 6 and the upper cover plate 1 are provided with a bottom plate in the welding cavity, and there are many holes for accommodating printed board components on the bottom plate A groove 5, the wall position of the welding cavity of the lower cover plate 6 is provided with a positioning step;

[0021] The left and right ears of the lower cover 6 are fixed with positioning pins 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com