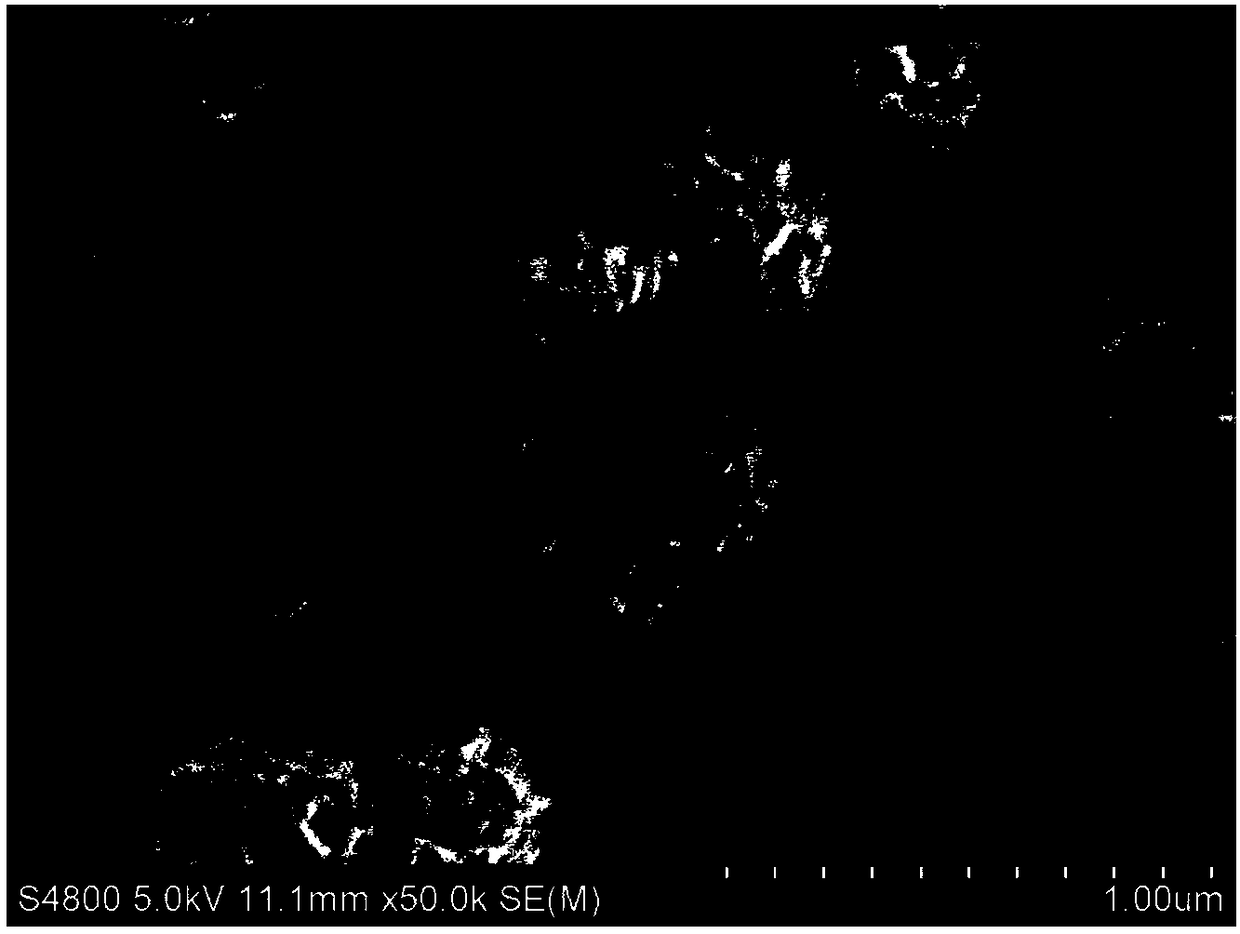

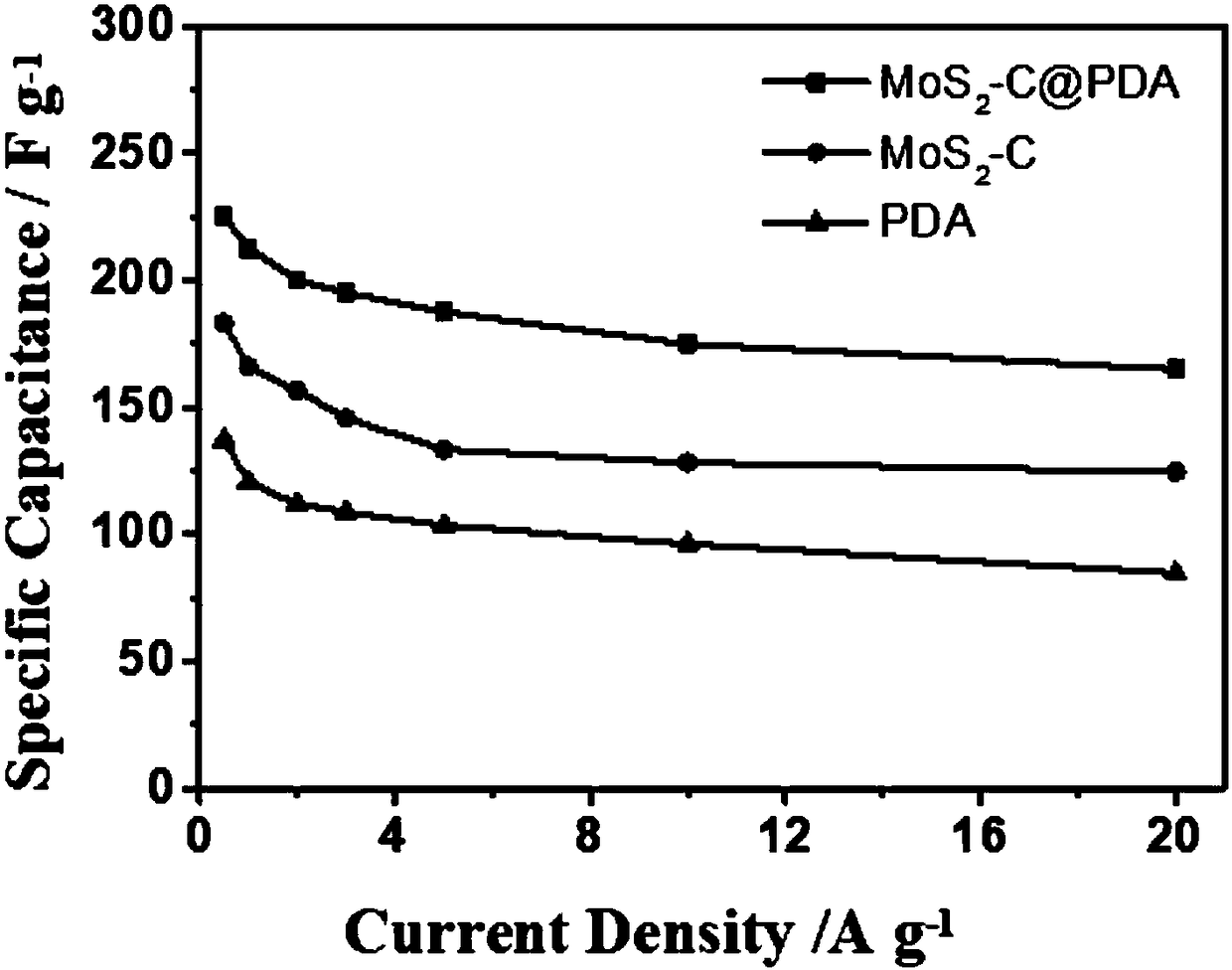

Molybdenum disulfide/porous carbon nanosphere composite material and preparation method thereof

A technology of molybdenum disulfide and composite materials, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems that molybdenum disulfide-based electrodes cannot adapt to the rapid diffusion of electron ions, unsatisfactory rate performance, and limited wide application, etc., and achieve excellent cycle characteristics, The effect of high specific capacity and enhanced cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for preparing a molybdenum disulfide / porous carbon nanosphere composite material, comprising the following steps:

[0045] ① Dissolve 1.0g of polyether F127 in a beaker filled with 2ml of mesitylene and 50ml of ethanol, stir magnetically for 30min; then add 50ml of deionized water to obtain a milky white solution.

[0046] ②Add 1.5g of dopamine hydrochloride to the milky white solution, ultrasonically treat for 30 minutes to obtain a uniformly dispersed emulsion, then slowly add 3.75ml of ammonia water, keep magnetic stirring, and react at room temperature for 12 hours.

[0047]③ After the reaction, centrifuge the solution at a speed of 10000r / min for 10 minutes to collect the black precipitate; dissolve the black precipitate in a mixed solution of ethanol and deionized water with a volume ratio of 1:1, and pour the mixed solution into a hydrothermal reaction kettle reaction at a temperature of 100° C. for 24 hours. After the reaction w...

Embodiment 2

[0055] This embodiment provides a method for preparing a molybdenum disulfide / porous carbon nanosphere composite material, comprising the following steps:

[0056] ① Dissolve 0.5g of polyether F127 in a beaker filled with 1ml of mesitylene and 50ml of ethanol, stir magnetically for 20min; then add 30ml of deionized water to obtain a milky white solution.

[0057] ②Add 1g of dopamine hydrochloride to the milky white solution, ultrasonically treat for 20min to obtain a uniformly dispersed emulsion, then slowly add 2.5ml of ammonia water, keep magnetic stirring, and react at room temperature for 8h.

[0058] ③ After the reaction, centrifuge the solution at a speed of 6000r / min for 5 minutes to collect the black precipitate; dissolve the black precipitate in a mixed solution of ethanol and deionized water with a volume ratio of 1:1, and pour the mixed solution into a hydrothermal reaction kettle reaction at a temperature of 80°C for 20 hours, after the reaction was completed, wash...

Embodiment 3

[0064] This embodiment provides a method for preparing a molybdenum disulfide / porous carbon nanosphere composite material, comprising the following steps:

[0065] ① Dissolve 2.5g of polyether F127 in a beaker containing 2.5ml of mesitylene and 50ml of ethanol, and stir for 40min with magnetic force; then add 60ml of deionized water to obtain a milky white solution.

[0066] ② Add 2.5g of dopamine hydrochloride to the milky white solution, ultrasonically treat for 40min to obtain a uniformly dispersed emulsion, then slowly add 5ml of ammonia water, keep magnetic stirring, and react at room temperature for 24h.

[0067] ③ After the reaction, centrifuge the solution at a speed of 12000r / min for 15 minutes to collect the black precipitate; dissolve the black precipitate in a mixed solution of ethanol and deionized water with a volume ratio of 1:1, and pour the mixed solution into a hydrothermal reaction kettle reaction at a temperature of 110°C for 24 hours. After the reaction wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com