Efficient-filtering exhaust hood with no need for dismounting and washing

A technology for washing range hoods and high-efficiency filtration, which is applied in the fields of oil fume removal, household heating, lighting and heating equipment, etc. It can solve the problems of replacement and maintenance of filter devices, unsatisfactory filtering effect, and fast flow rate, etc., and achieves a direct noise reduction effect High efficiency, low cost, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

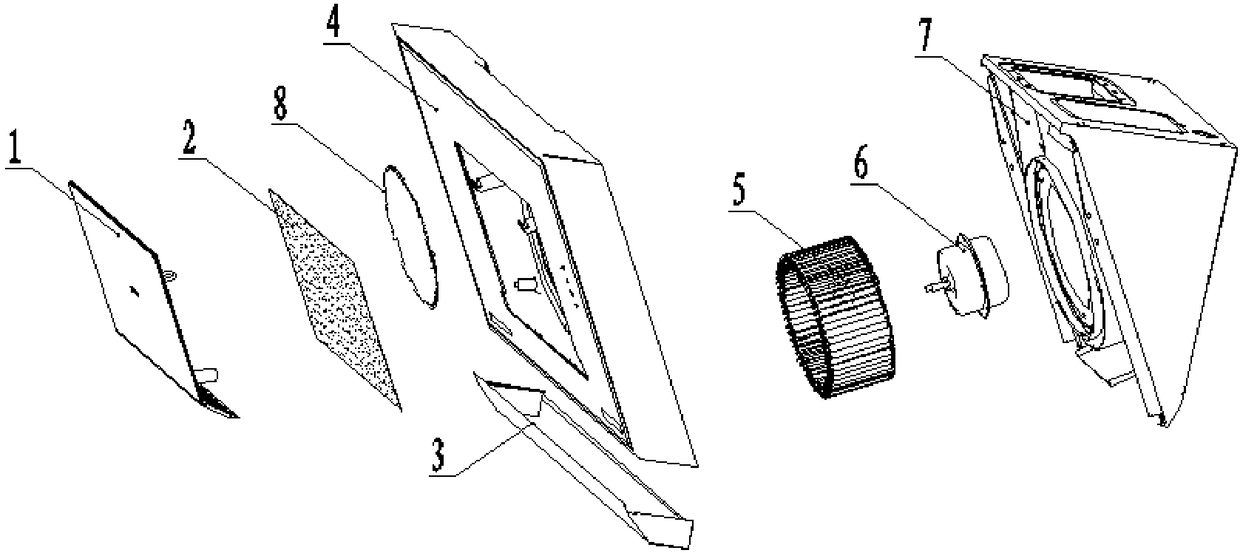

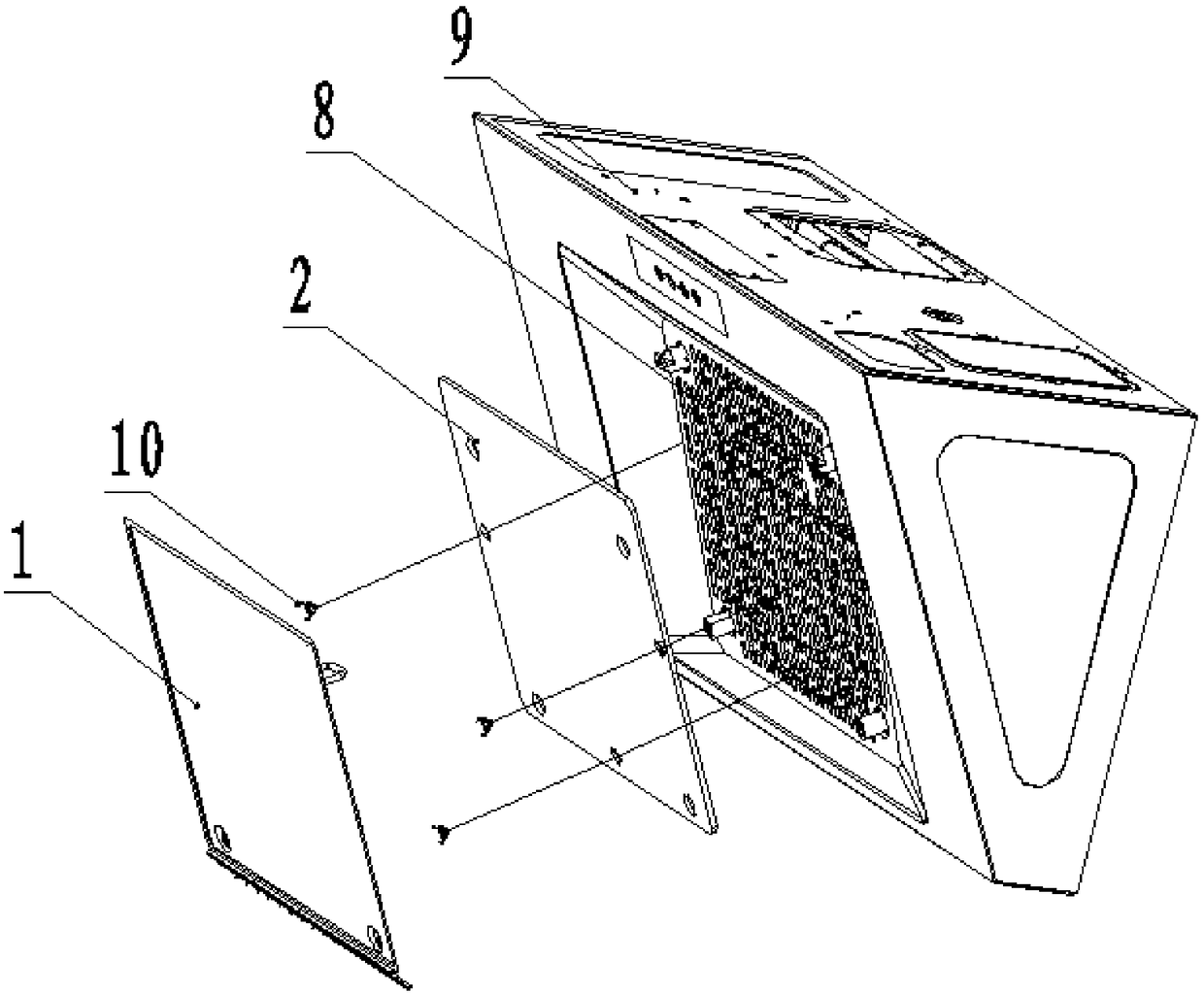

[0029] Embodiment 1: This high-efficiency filter-free range hood mainly includes a wind deflector 1, a net cover 8, an air duct 7 and a casing 9, the air duct 7 is fixed inside the casing 9, and the air duct 7 and the casing 9 are connected by screws. Together, the wind deflector 1 is located at the front end of the air inlet of the air duct 7, the net cover 8 is located in the air duct 7, and the front portion of the net cover 7 is provided with a detachable disposable high-efficiency filter screen 2. While improving the filtration efficiency, it ensures that the inside of the fan system does not enter the oil fume, and realizes that the inside does not need to be dismantled and cleaned.

[0030] The filter screen has high filtration efficiency and can filter out most of the grease to protect the long life of the internal components of the range hood; the cost is extremely low, and when the grease is collected, it can be discarded and replaced with a new filter screen to ensur...

Embodiment 2

[0031] Embodiment 2: On the basis of Embodiment 1, the net cover 8 is located at the air inlet of the air duct 7, the high-efficiency filter screen 2 is located at the air inlet of the air duct 7 and the front end of the net cover 8, and the air duct 7 is provided with mutual Cooperating impeller 5 and motor 6, the front part of air channel 7 is provided with smoke collection hood 4, and wind deflector 1 is fixed on the smoke collection hood 4, and the bottom of smoke collection hood 4 is provided with oil cup 3.

[0032] The air duct 7 is mainly responsible for the power part of the range hood. The motor 6 drives the rotation of the impeller 5 to discharge the air outside through the smoke exhaust pipe. Nip area: the high-efficiency filter screen 2 is set at the air inlet and the front end of the net cover 3, and the oil fume mixed air containing grease is first filtered and collected through the high-efficiency filter screen 2, and then filtered through the net cover 8 for a ...

Embodiment 3

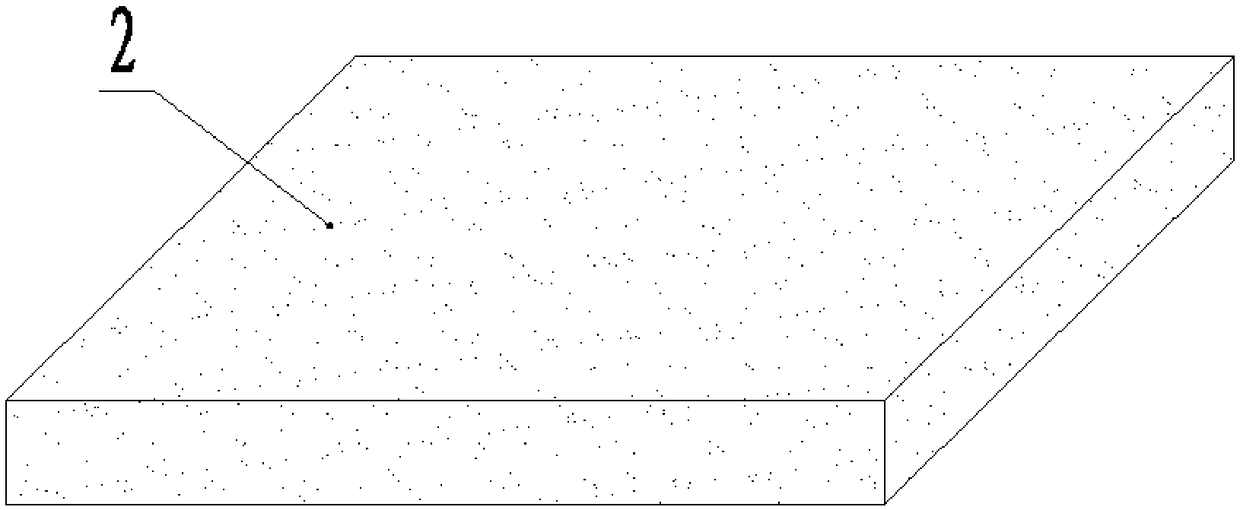

[0035] Embodiment 3: On the basis of Embodiment 2, the high-efficiency filter screen 2 is filter cotton, which is a composite fiber net, which is processed by using composite fibers in different proportions. The high-efficiency filter screen 2 is mainly composed of polyester fiber, PP fiber, PET fiber and other high-performance anti-break synthetic fibers obtained after compounding. The fiber arrangement of the high-efficiency filter screen 2 is in an increasing structure, from the air inlet direction to the air outlet direction The density gradually increases. The thickness of the high-efficiency filter 2 is most suitable between 10-30mm, and the weight is 100-300g / m 2 The most suitable, flame retardant, safe and reliable, and the main material is non-toxic, non-polluting, and harmless to the human body. The high-efficiency filter screen 2 is made through cotton blending, opening, carding, net laying, hot air setting, cold air setting, punching, and edge sealing. Good filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com