Reinforcing rib profile steel fixing base

A technology for fixing the base and reinforcing ribs, which is applied in the direction of fixing devices, slender elements, building elements, etc. It can solve problems such as the low degree of fit between the connecting piece and the section steel, poor stability of the section steel connection structure, and no guarantee for connection safety, etc., to achieve Increase mechanical properties, ensure adjustability, and improve strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

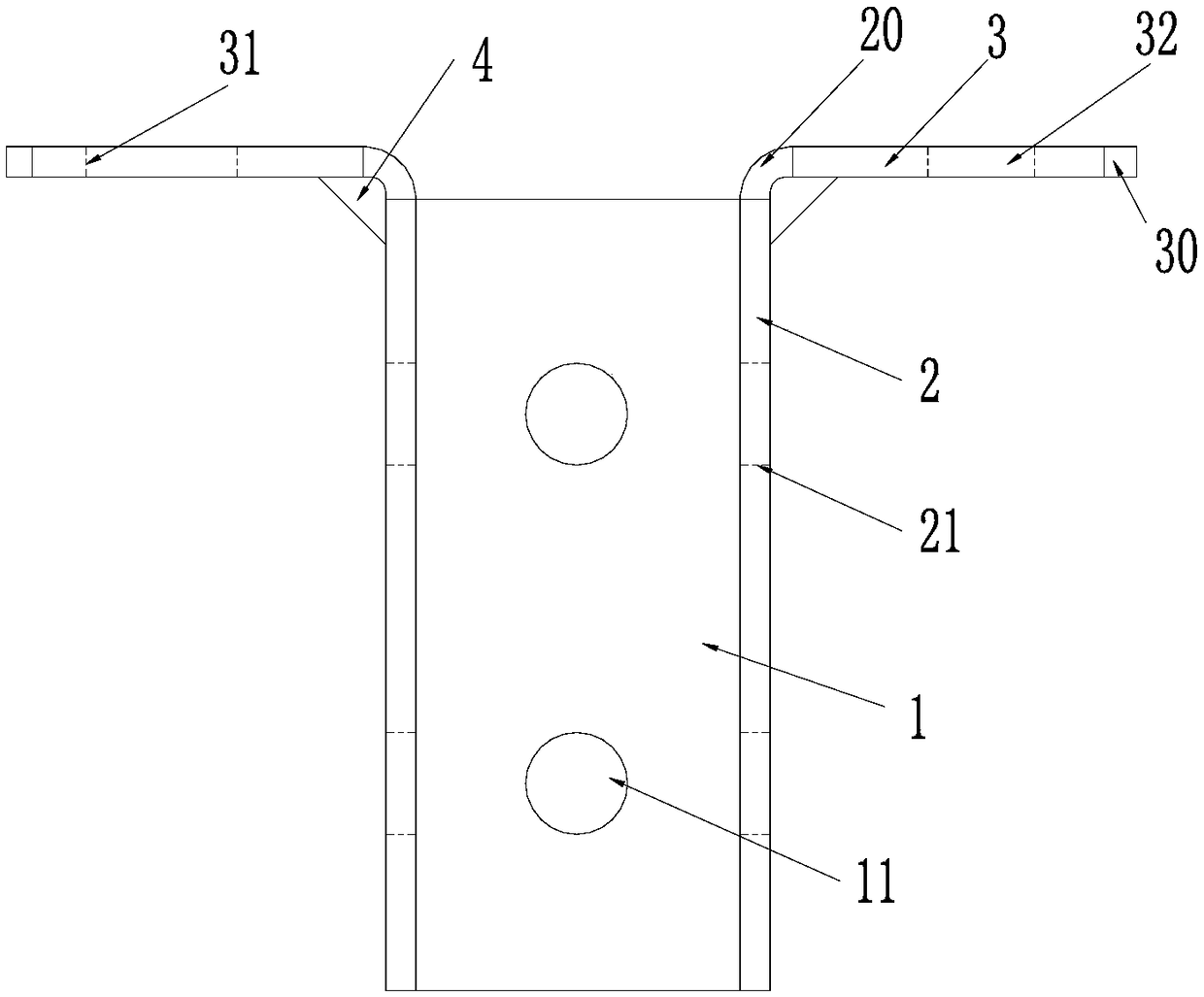

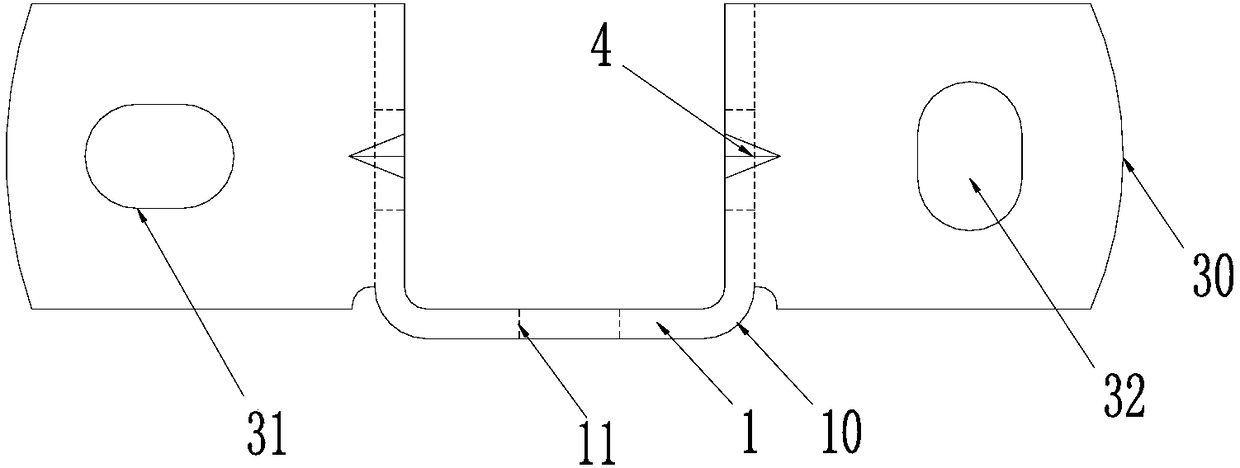

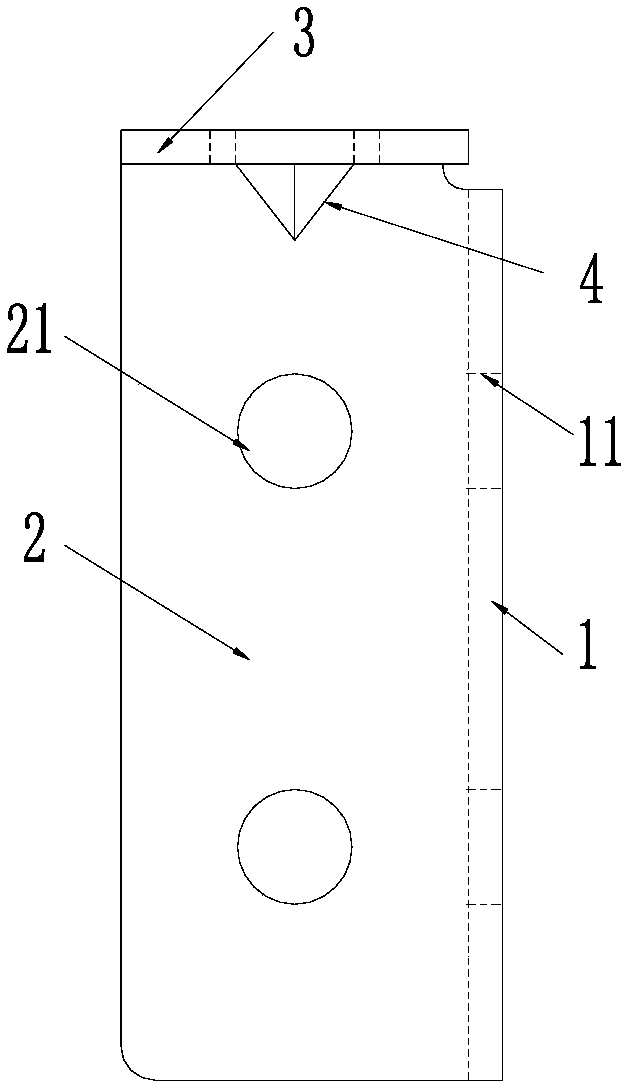

[0016] refer to Figure 1 to Figure 5 , a rib-shaped steel fixed base of the present invention, including a mounting web 1, a limiting wing 2, a base support plate 3 and a reinforcing rib 4, the two sides of the mounting web 1 are symmetrically provided with a limiting wing 2, so The end of the limit wing plate 2 extends outwards with a base support plate 3, the base support plate 3 is perpendicular to the limit wing plate 2, and the connection between the base support plate 3 and the limit wing plate 2 is provided with a reinforcement Rib 4, several first installation holes 11 are opened on the installation web 1, several second installation holes 21 are opened on the limiting wing plate 2, and connection waist holes are opened on the base support plate 3 . The installation web 1 is perpendicular to the limiting wing 2 , and the connection between the installation web 1 and the limiting wing 2 is provided with a first arc transition 10 . The end of the base support plate 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com