Vertical spliced type underground diaphragm wall and construction method thereof

An underground diaphragm wall and construction method technology, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problem of the overall rigidity of the diaphragm wall, the decline in deformation resistance, the inability of adjacent wall sections to leak water, and the weakening of reinforced concrete Stress conditions and other issues, to achieve the effect of good project implementation, low construction difficulty, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

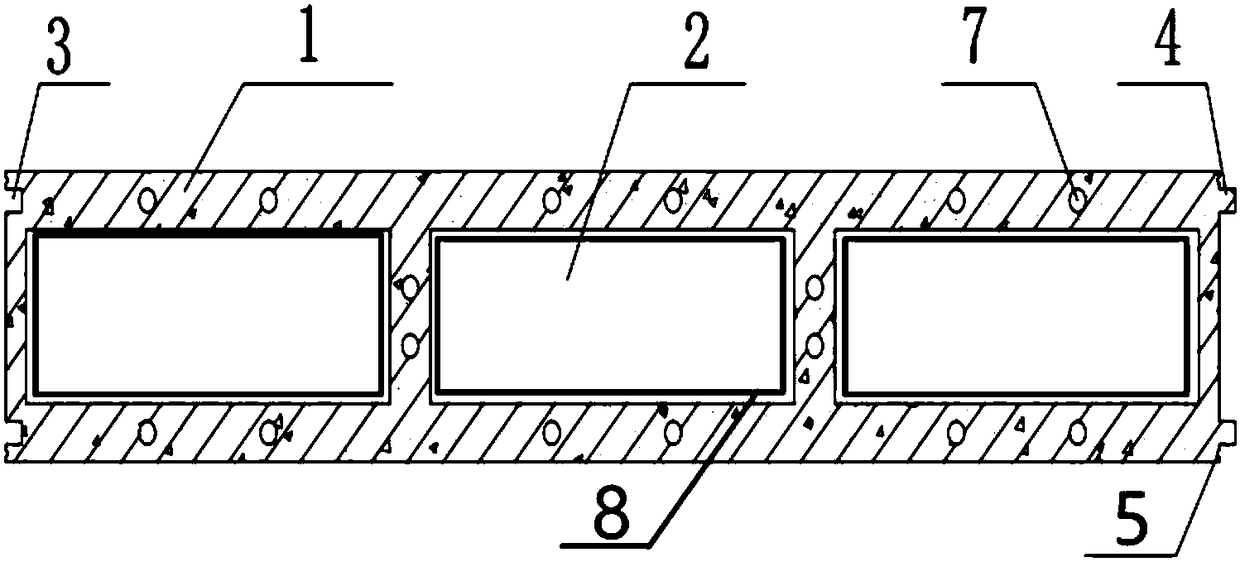

[0043] Such as Figure 1-6As shown, a vertically spliced underground continuous wall provided by the present invention includes a continuous wall 1, and each continuous wall 1 is formed by splicing at least three continuous wall units vertically, and is divided into three sections from top to bottom. The upper diaphragm wall unit 11, the middle diaphragm wall unit 12 and the lower diaphragm wall unit 13, each diaphragm wall unit has a length of 6m, a thickness of 1m, and a height of 10m, and there are three vertical and vertical through-holes arranged in equal parallel inside. The cavity 2 of 50cm*150cm*1000cm is connected with the steel cage 8 inside the cavity 2, and one end of each continuous wall unit is provided with an inwardly recessed female interface 3, and the other end is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com