Equipment convenient for mounting bridge support

A bridge support and equipment technology, applied in the field of equipment that facilitates the installation of bridge supports, can solve problems such as deformation of pre-embedded steel bars and difficulties in installing bridge supports, and achieve the effects of improving the use effect, saving procedures, and facilitating the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

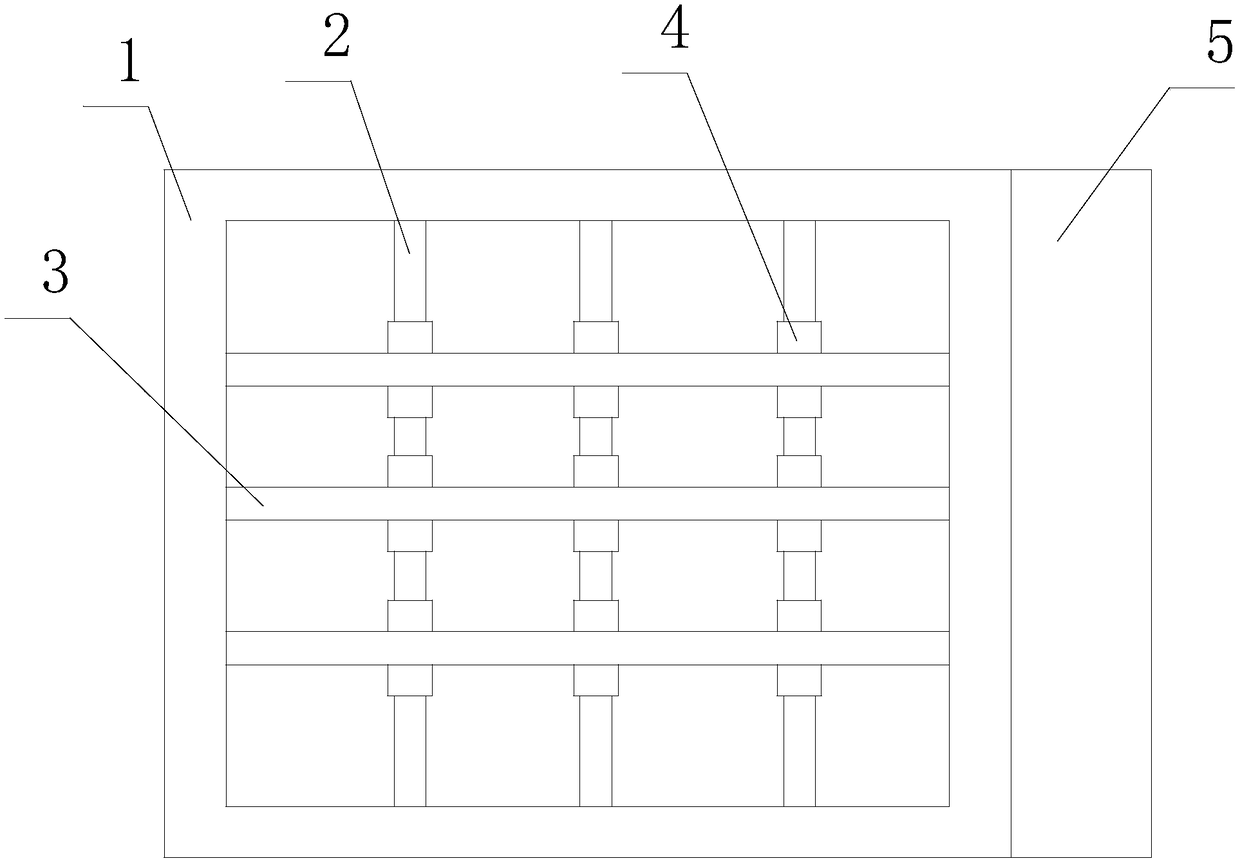

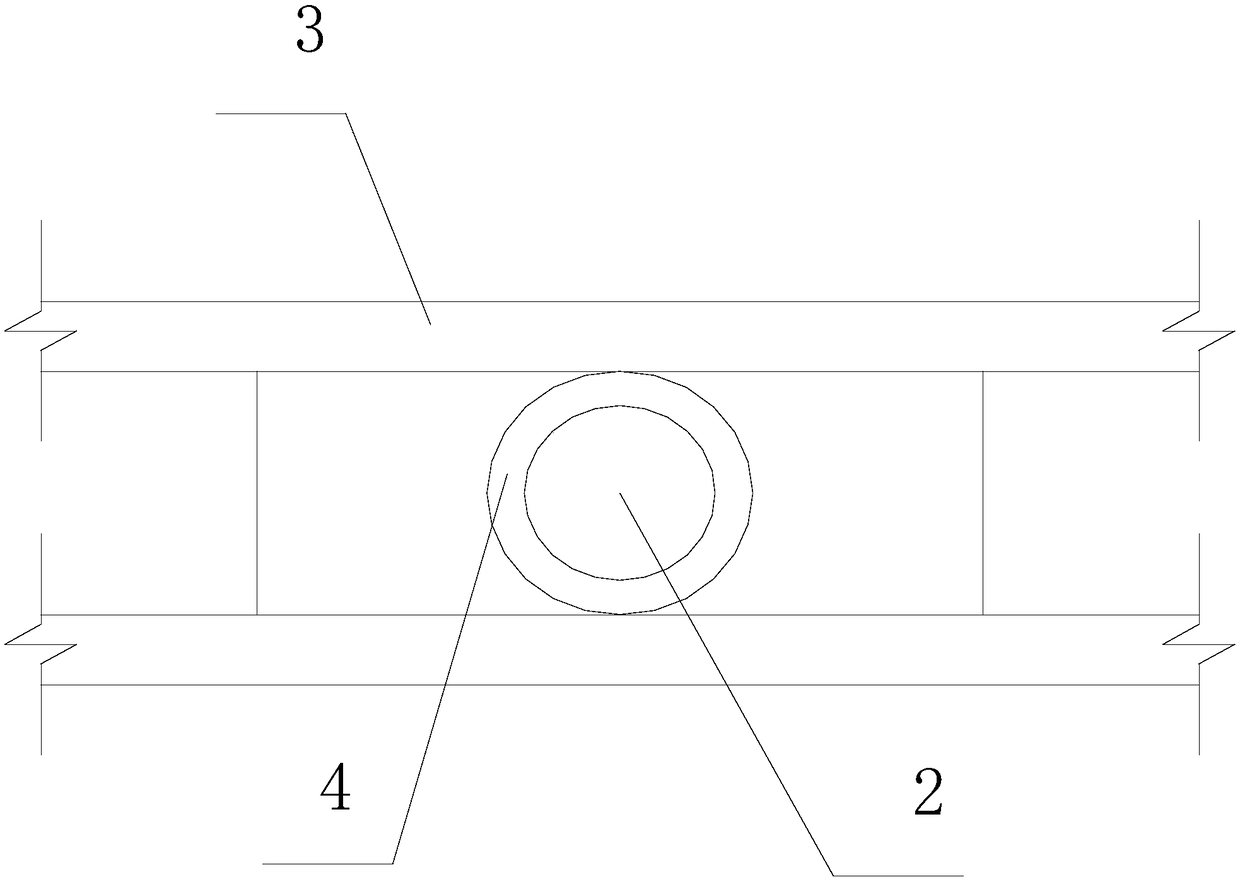

[0039] Such as figure 1 , figure 2 and image 3 As shown, the present invention facilitates the installation of bridge supports, including a frame 1, a longitudinal clamp bar 2, a transverse clamp bar 3 and a sleeve 4; the longitudinal clamp bar 2 and the transverse clamp bar 3 are movably arranged inside the frame 1, and The angle between the longitudinal clamping bar 2 and the transverse clamping bar 3 is 90°; the intersecting longitudinal clamping bar 2 and the transverse clamping bar 3 are movably connected through the sleeve 4; The cylinder 4 moves longitudinally along the transverse clamp rod 3 in the through hole; the outer surface of the sleeve 4 is provided with a spring ball 6 longitudinally along the transverse clamp rod 3; the longitudinal clamp rod 2 is arranged inside the sleeve 4 and along the The longitudinal clamping rod 2 moves longitudinally; the inner wall of the sleeve 4 is provided with balls longitudinally along the longitudinal clamping rod 2 .

[0...

Embodiment 2

[0043] In this embodiment, on the basis of Embodiment 1, the longitudinal clamping bar 2 and the horizontal clamping bar 3 are movably connected to the frame 1, and the longitudinal clamping bar 2 moves longitudinally along the horizontal clamping bar 3, and the horizontal clamping bar 3 moves along the longitudinal clamping bar 2. longitudinal movement.

[0044] During the implementation of this embodiment, in order to enable the longitudinal clamping bar 2 and the horizontal clamping bar 3 to better complete the clamping of the pre-embedded steel bars, the present invention limits the moving direction of the longitudinal clamping bar 2 and the horizontal clamping bar 3 .

Embodiment 3

[0046] Such as figure 1 As shown, on the basis of Embodiment 1, this embodiment further includes a transmission device 5; the transmission device 5 is connected to the longitudinal clamping rod 2 and the lateral clamping rod 3 through a screw.

[0047] When this embodiment is implemented, the pre-embedded steel tends to bear a relatively large stress. When the longitudinal clamping bar 2 and the horizontal clamping bar 3 are adjusted completely by manpower, it is easy to have a large error. Therefore, the present invention uses the transmission device 5 to amplify the power or Adding external power to the transmission device can effectively improve the use effect of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com