Microalloyed Ti-Zr-Hf-V-Nb-Ta refractory high-entropy alloy and preparation method thereof

A ti-zr-hf-v-nb-ta, high-entropy alloy technology, applied in the field of metal materials, can solve problems such as poor plasticity of refractory high-entropy alloys, and achieve the effects of high strength, simple operation and good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

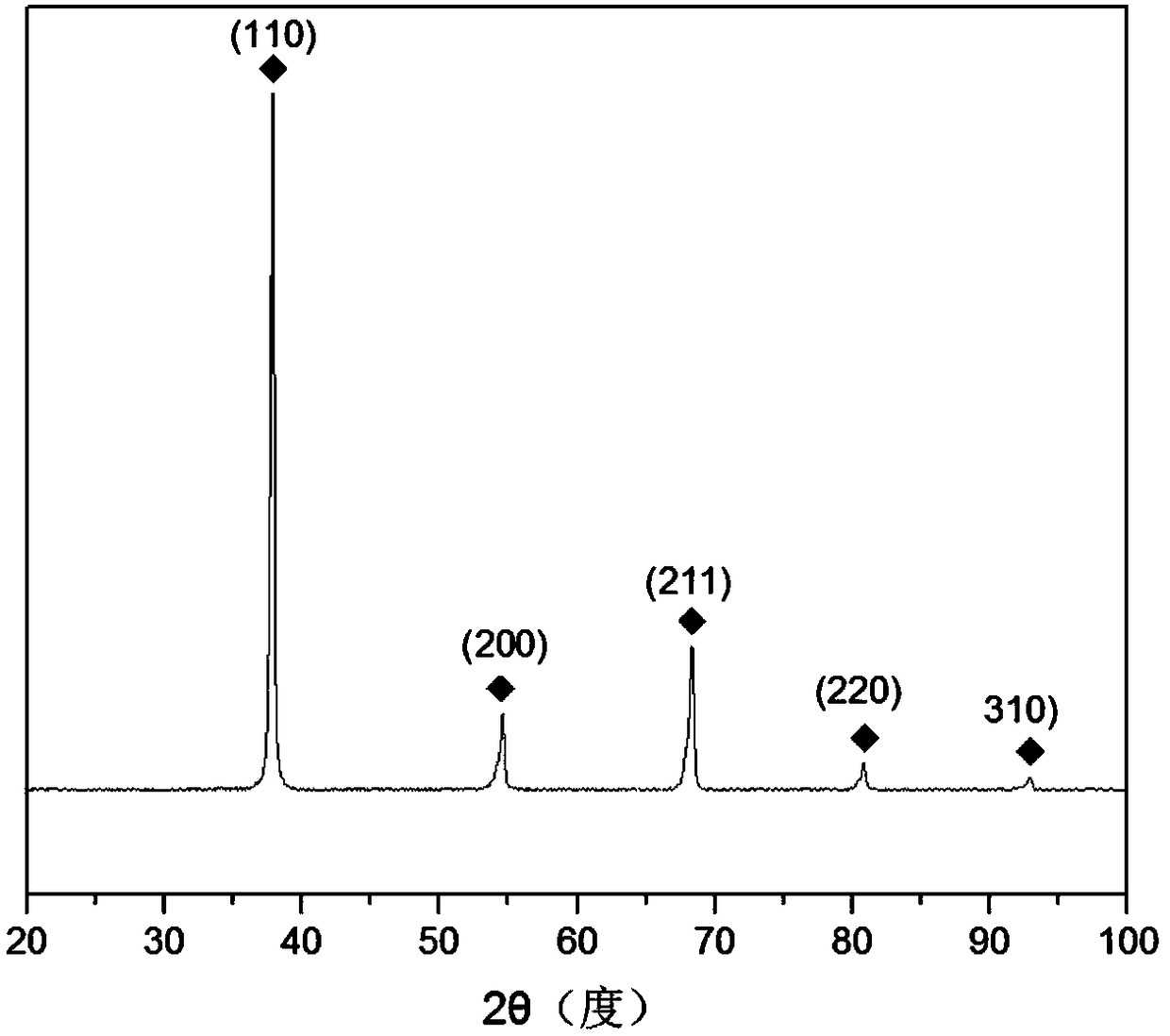

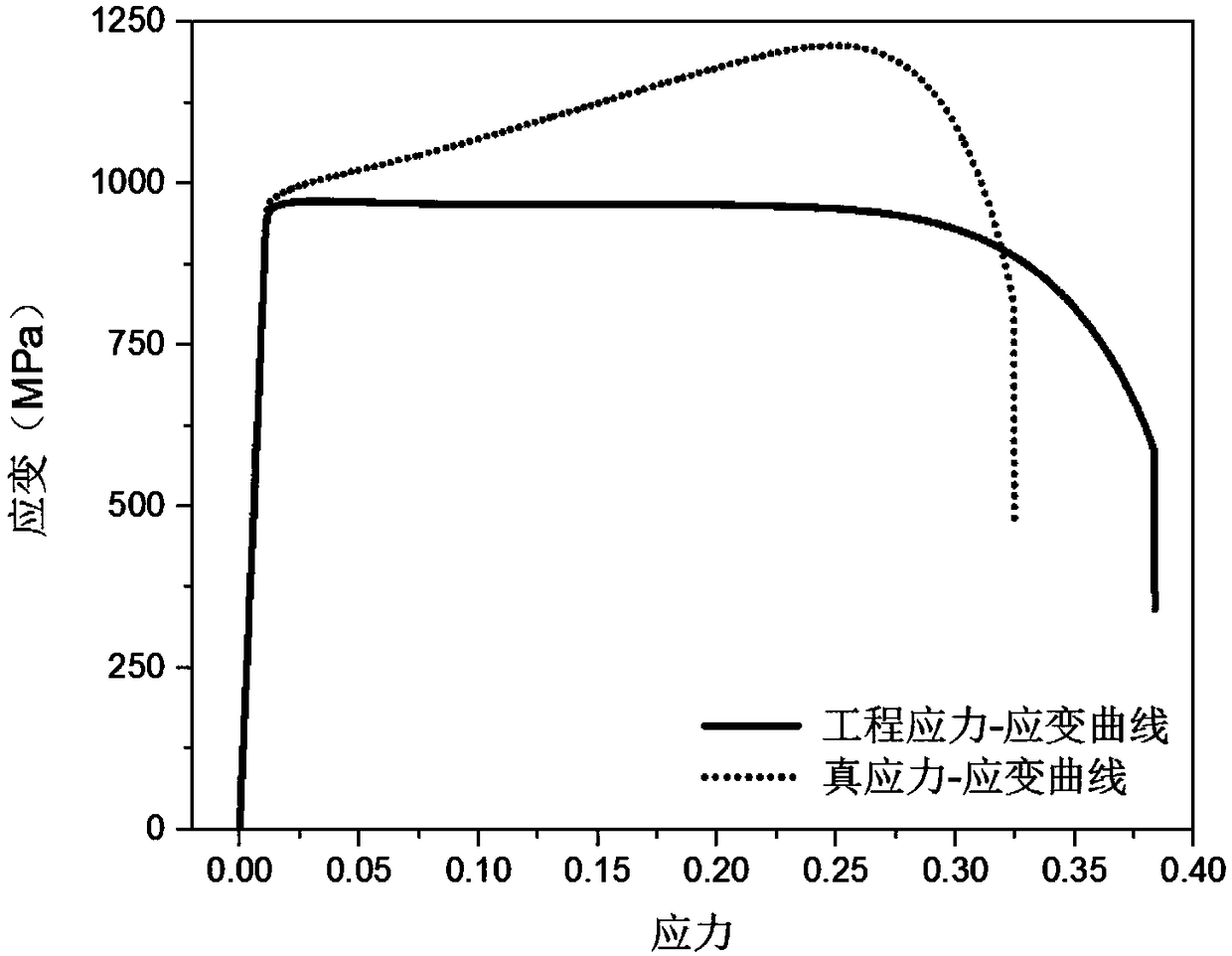

Embodiment 1

[0044] Ti 32 Zr 30 f 5 V 10 Nb 13 Ta 5 Al 5 The specific preparation steps of the refractory high-entropy alloy are as follows:

[0045] (1) Using elemental Ti, Zr, Hf, V, Nb, Ta and Al with a purity of more than 99.7wt% as raw materials, first remove the scale on the surface of the raw materials by grinding with a grinding wheel, and then use absolute ethanol to carry out ultrasonic vibration cleaning to obtain Clean raw materials, and according to the atomic percentage of Ti:Zr:Hf:V:Nb:Ta:Al=32:30:5:10:13:5:5, weigh out the clean raw materials with a total mass of (80±0.01)g raw material;

[0046] (2) Put the weighed elemental Hf, Nb and Ta into a water-cooled copper crucible in a high-vacuum non-consumable arc melting furnace, and then vacuumize until the vacuum in the melting furnace reaches 2.5×10 -3 After Pa, fill high-purity argon as a protective gas; before melting the alloy, first melt the pure titanium metal ingot to further reduce the oxygen content in the f...

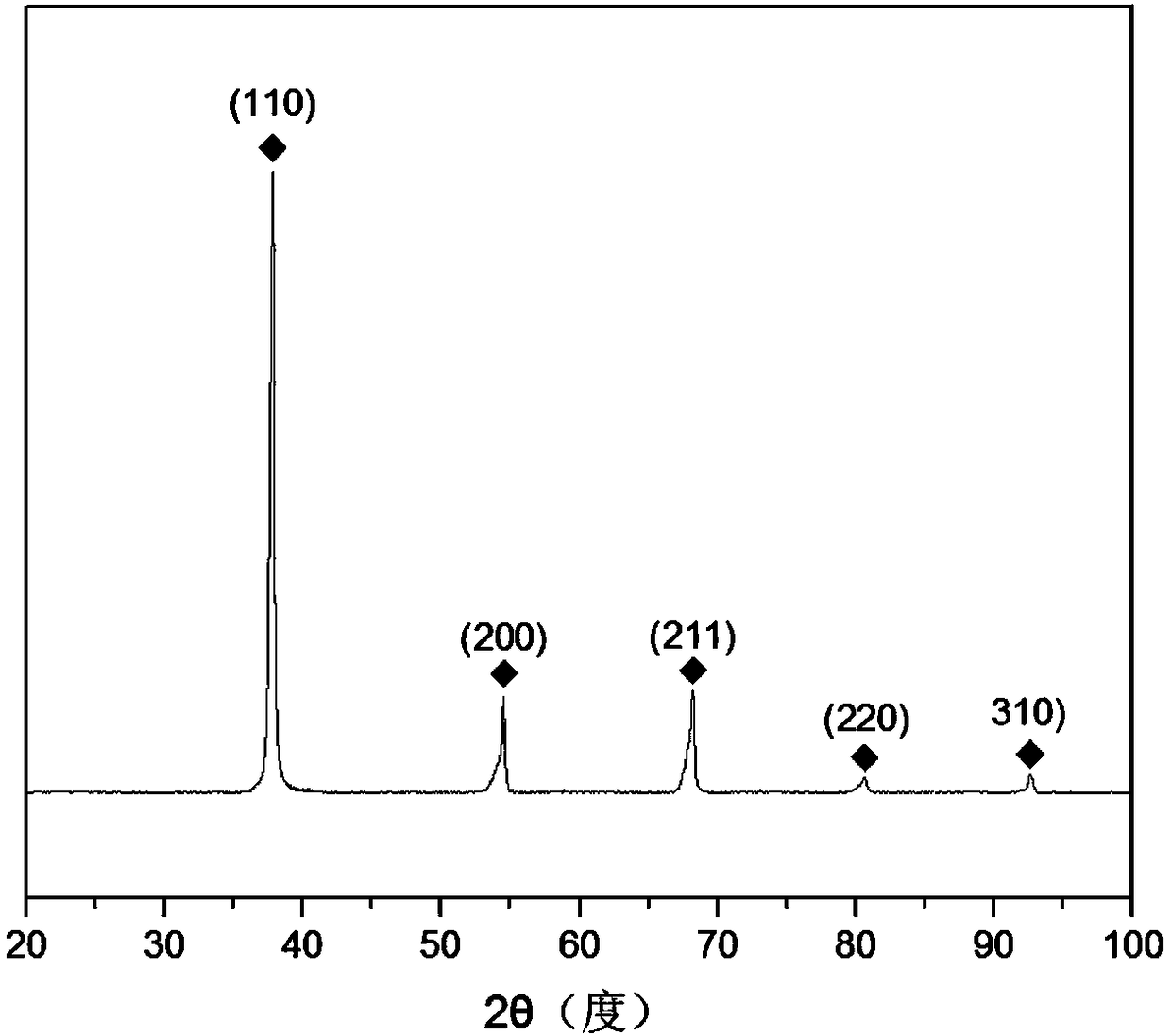

Embodiment 2

[0051] Ti 42 Zr 15 f 15 Nb 12 Ta 10 Al 6 The specific preparation steps of the refractory high-entropy alloy are as follows:

[0052] (1) Using elemental Ti, Zr, Hf, Nb, Ta and Al with a purity of more than 99.7wt% as raw materials, first remove the scale on the surface of the raw materials by grinding with a grinding wheel, and then use absolute ethanol to carry out ultrasonic vibration cleaning to obtain clean Raw materials, and according to the atomic percentage of Ti:Zr:Hf:Nb:Ta:Al=42:15:15:12:10:6, weigh the clean raw materials with a total mass of (80±0.01) g;

[0053] (2) Put the weighed elemental Hf, Nb and Ta into a water-cooled copper crucible in a high-vacuum non-consumable arc melting furnace, and then vacuumize until the vacuum in the melting furnace reaches 2.5×10 -3 After Pa, fill high-purity argon as a protective gas; before melting the alloy, first melt the pure titanium metal ingot to further reduce the oxygen content in the furnace cavity, and then car...

Embodiment 3

[0058] Ti 30 Zr 8 f 20 Nb 8 Ta 30 Al 4 The specific preparation steps of the refractory high-entropy alloy are as follows:

[0059] (1) Using elemental Ti, Zr, Hf, Nb, Ta and Al with a purity of more than 99.7wt% as raw materials, first remove the scale on the surface of the raw materials by grinding with a grinding wheel, and then use absolute ethanol to carry out ultrasonic vibration cleaning to obtain clean Raw materials, and according to the atomic percentage of Ti:Zr:Hf:Nb:Ta:Al=30:8:20:8:30:4, weigh the clean raw materials with a total mass of (80±0.01) g;

[0060] (2) Put the weighed elemental Hf, Nb and Ta into a water-cooled copper crucible in a high-vacuum non-consumable arc melting furnace, and then vacuumize until the vacuum in the melting furnace reaches 2.5×10 -3 After Pa, fill high-purity argon as a protective gas; before melting the alloy, first melt the pure titanium metal ingot to further reduce the oxygen content in the furnace cavity, and then carry o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com