Acinetobacter oleivorans NMB 17, and applications thereof in plant disease prevention and treatment

A bacillus and plant technology, applied in applications, animal repellents, plant growth regulators, etc., can solve problems such as unsatisfactory control effects, pathogenic bacteria resistance to human health, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

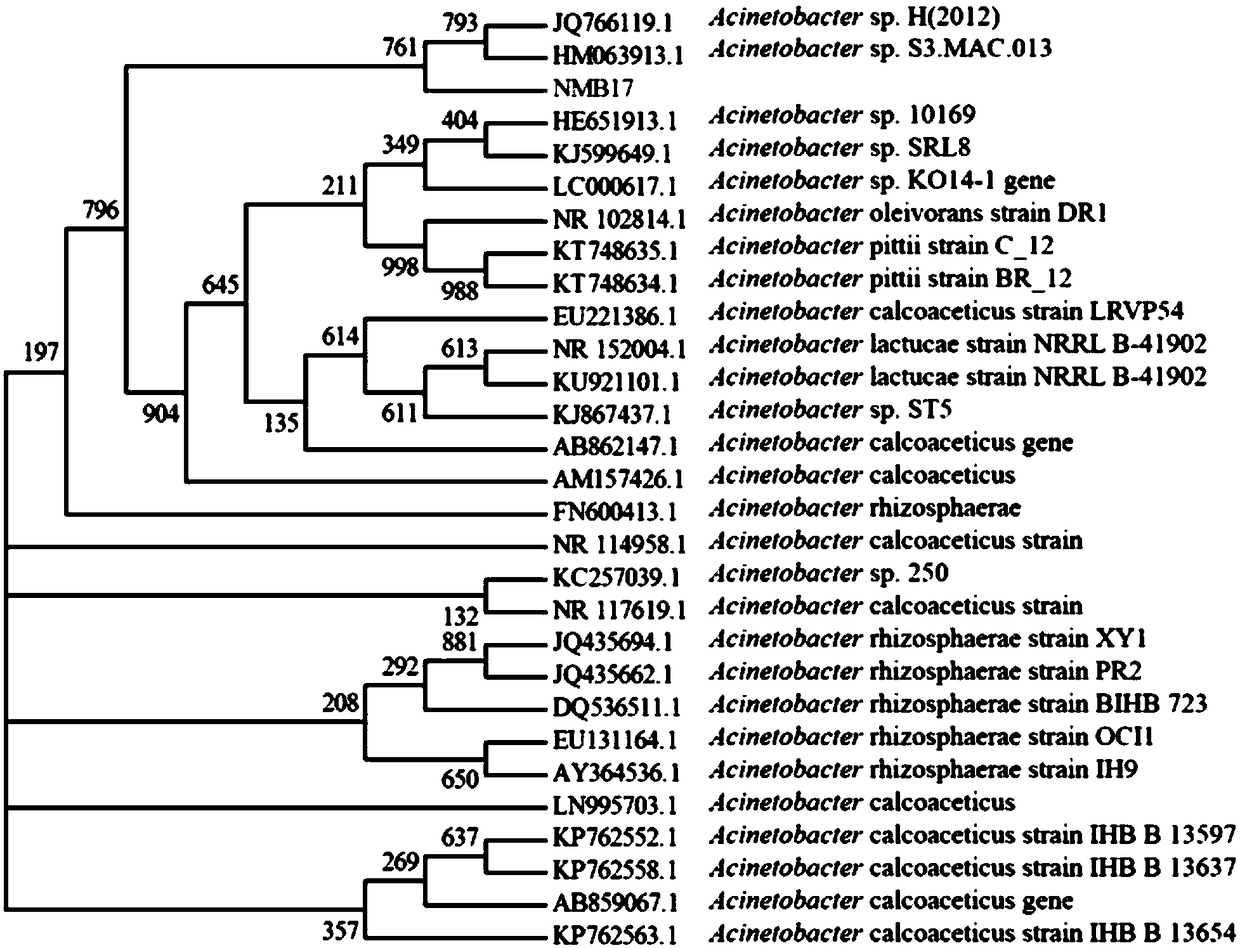

[0077] Embodiment 1, isolation and identification of NMB17 bacterial strain

[0078] 1. Isolation of NMB17 strain

[0079] The NMB17 strain was isolated from the rhizosphere soil where the sugar beet root rot was severe in the sugar beet continuous cropping plot in Ulanqab City, Inner Mongolia Autonomous Region. The specific separation method is as follows: pick the rhizosphere soil collected from the sugar beet continuous cropping plot, pick the root system, scrape the rhizosphere soil, weigh 5g, put it into the prepared sterilized triangular flask under aseptic conditions, and wash it with sterilized water. The gradient was diluted to 10-6 times, and 3 replicates were set. Take 200 μL of the soil samples that were diluted in gradient and spread them on the PDA medium plate respectively, cultivate them in a 28°C incubator, and observe the growth status of the colonies every day. Basically no colony grows on the plate, and when the dilution is 10-4 times, a single colony can...

Embodiment 2

[0096] Embodiment 2, the preparation of microbial NMB17 bacterial agent, fermented liquid and metabolic liquid

[0097] 1. Preparation of microbial NMB17 bacterial agent

[0098] Inoculate the Acinetobacter oleophilus NMB17 obtained in Example 1 into LB medium, shake and culture at 28°C and 200rpm for 12-16h, then centrifuge at 4000rpm for 20min, discard the supernatant, collect the bacterial precipitate, and use Sterilized water is used to dilute the bacterial precipitate to make microbial NMB17 bacterial agent, and the total concentration of NMB17 viable bacteria in the finished product of microbial NMB17 bacterial agent is 1×10 9 -1×10 10 CFU / mL.

[0099] 2. Preparation of microbial NMB17 fermentation broth

[0100] The Acinetobacter oleophilus NMB17 obtained in Example 1 was inoculated in LB culture medium, shaken and cultured at 28°C and 200rpm for 12-16h, then centrifuged at 4000rpm for 20min, and the supernatant was collected, which was the microbial NMB17 fermentati...

Embodiment 3

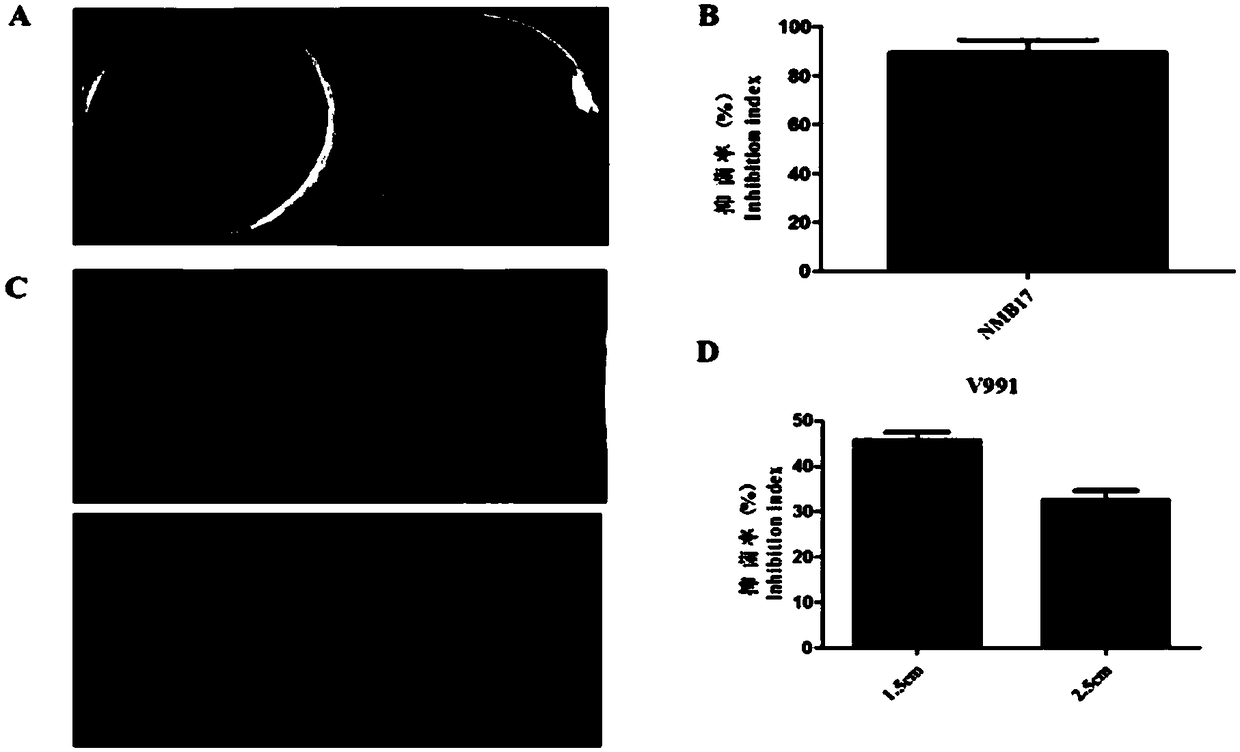

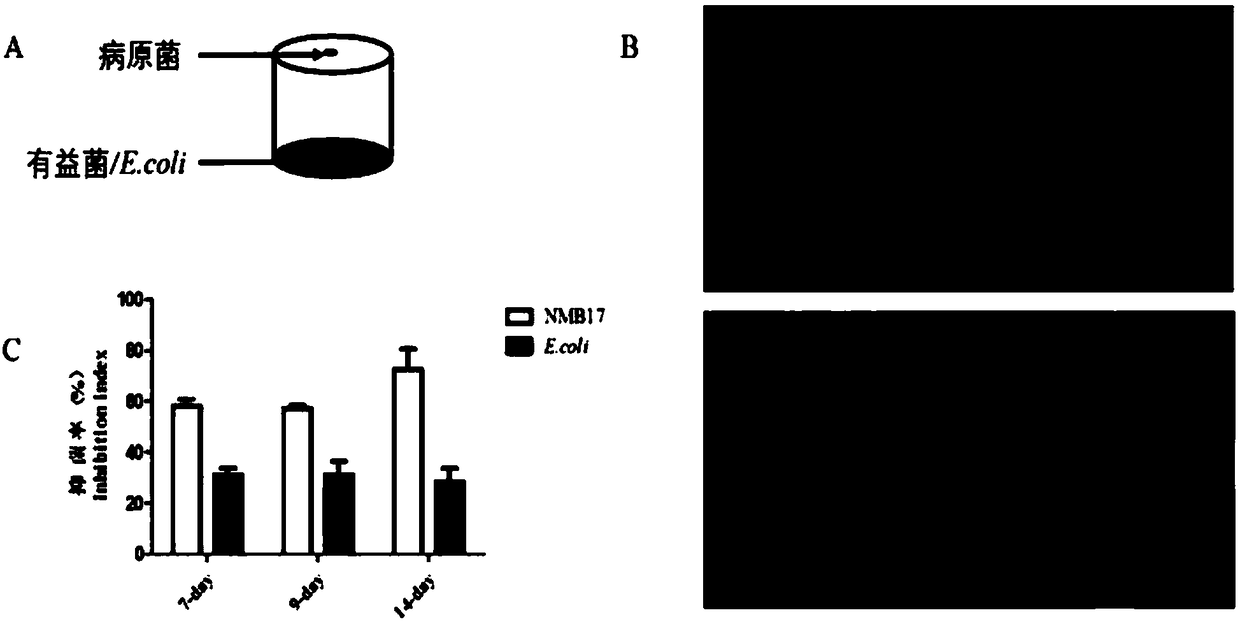

[0103] Embodiment 3, the influence of microorganism NMB17 fermented liquid and bacterial agent on the antibacterial rate of cotton Verticillium dahliae V991

[0104] 1. Experimental method

[0105] 1. Add the NMB17 fermentation broth to the PDA medium that has been melted and cooled to about 50°C according to the volume ratio of 1:25, mix well and spread the plate to obtain the PDA medium containing the NMB17 fermentation broth. At the same time, the PDA medium without any bacterial agent was set as the control.

[0106] The PDA medium without adding any bacterial agent was spread on the plate, and the center point of the plate was drawn by the cross method, and holes were punched at 1.5cm and 2.5cm away from the center point respectively, and then the diameter of the hole was punched. For a 5cm round hole, add 10 μl of NMB17 bacterial agent to the round hole, and use 10 μl of sterilized water as a control, place it in an ultra-clean bench and wait for the bacteria solution a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper mouth diameter | aaaaa | aaaaa |

| Lower mouth diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com