Biodegradable polyester composition and application thereof

A composition and polyester technology, applied in the field of polymer material modification, can solve the problems of low biodegradation percentage and refractory degradation, and achieve the effects of low toxicity, high transparency and high strength

Active Publication Date: 2018-06-29

杨红梅

View PDF8 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Patent CN 102597105 B discloses that currently commercially available polyesters generally have an amount of aromatic carboxylic acids of less than 48 mole %, because above this threshold, the percentage of biodegradation of such polyesters will be significantly reduced, in industrial composting or household composting Under the conditions, it is difficult to effectively degrade

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

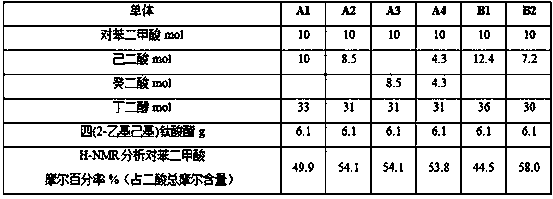

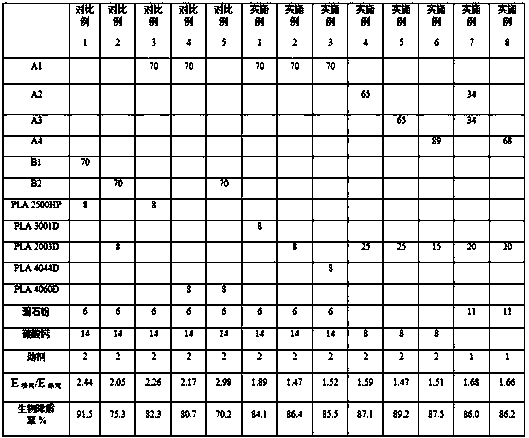

Embodiment 1-8 and comparative example 1-5

[0053] Mix aliphatic-aromatic copolyester, polylactic acid, inorganic filler and additives (white mineral oil) evenly according to the formula in Table 2, put them into a twin-screw extruder, extrude and pelletize at 140°C-170°C , to obtain a biodegradable polyester composition, the biodegradable polyester composition was prepared into a 12±1 μm film for testing, and the performance results are shown in Table 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a biodegradable polyester composition. The composition is prepared from the following components: (i) 50-94 parts by weight of aliphatic-aromatic copolyester, (ii) 5-30 parts by weight of polylactic acid, and (iii) 0.5-30 parts by weight of an inorganic filler. The composition is prepared by taking the aliphatic-aromatic copolyester having an aromatic carboxylic acid content of 48.5-54.5mol% as matrix resin, and using the polylactic acid having a melting point of 145-170 DEG C as an another phase; furthermore, the inorganic filler is added, so that the prepared biodegradable polyester composition has balanced longitudinal and transverse tearing properties; the polyester composition also has superior biodegradability, and the biodegradation rate of the composition reaches 80% or above in a degradation test process lasting for 12 weeks.

Description

technical field [0001] The invention belongs to the technical field of polymer material modification, and in particular relates to a biodegradable polyester composition and its application. Background technique [0002] At present, polyester compositions based on aliphatic polyester or aliphatic-aromatic copolyester are widely used in shopping bags, kitchen waste bags and other fields. The longitudinal and transverse tearing performance of the film is an important index to evaluate the performance of the prepared shopping bags, kitchen waste bags and other products. As described in patent CN 101522797 B, one drawback of the starch-based biodegradable bags currently on the market is the lack of uniformity in mechanical properties, especially tear strength in transverse and longitudinal directions. Films prepared from starch-based biodegradable polyester compositions have a thickness of 18-20 μm, but the films are still too pliable or too brittle to withstand a certain limit ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L67/02C08L67/04C08L91/06C08K3/34C08K3/26C08G63/183C08G63/85

CPCC08G63/183C08G63/85C08K2003/265C08L67/02C08L2201/06C08L2205/02C08L2205/03C08L67/04C08L91/06C08K3/34C08K3/26

Inventor 不公告发明人

Owner 杨红梅

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com