Hard PVC structural foam, and preparation method and shaping mold thereof

A technology for forming molds and PVC resins, applied in the field of foam materials, can solve problems such as high brittleness, shortened service life, and limited application range, and achieve the effects of light weight, increased back pressure, and improved melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

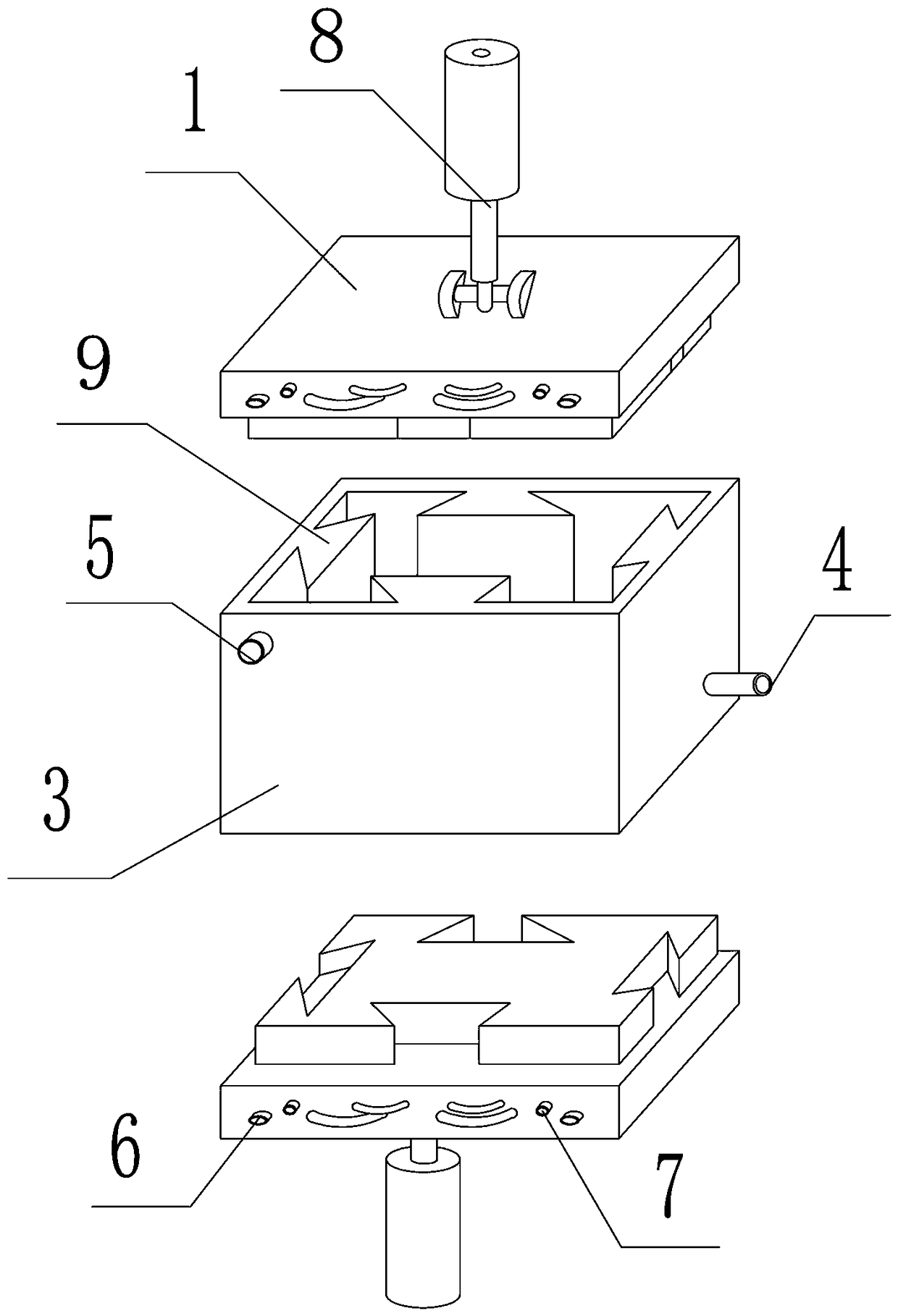

Image

Examples

Embodiment 1

[0030] This embodiment provides a rigid PVC structural foam, which is mainly prepared from the following raw materials in parts by weight: 150 parts of PVC resin, 30 parts of isocyanate, 2 parts of supercritical fluid foaming agent, and 1 part of water vapor. Wherein, the isocyanate is toluene diisocyanate, and the supercritical fluid blowing agent is supercritical carbon dioxide.

[0031] This embodiment also provides a method for preparing the rigid PVC structural foam, which specifically includes the following steps:

[0032] To prepare the foamed body, weigh PVC resin, isocyanate, supercritical carbon dioxide and water vapor according to the ratio of raw materials in the rigid PVC structural foam; heat the PVC resin to melt it, and add the isocyanate to it Melt and knead for 1 min, and obtain a foamed green body after cooling;

[0033] Perform primary foaming: place the foamed body in a closed mold cavity, heat the foamed body at a temperature of 60°C for 30 minutes to un...

Embodiment 2

[0046] This embodiment provides a rigid PVC structural foam, which is mainly prepared from the following raw materials in parts by weight: 110 parts of PVC resin, 45 parts of isocyanate, 3 parts of supercritical fluid foaming agent, and 0.5 part of water vapor. Wherein, the isocyanate is polymethylene polyphenyl polyisocyanate, and the supercritical fluid foaming agent is supercritical nitrogen.

[0047] This embodiment also provides a method for preparing the rigid PVC structural foam, which specifically includes the following steps:

[0048] Prepare the foamed body by weighing PVC resin, isocyanate, supercritical fluid foaming agent and water vapor according to the raw material ratio in the rigid PVC structural foam; heat the PVC resin to melt it, and then add the Melt and knead the isocyanate for 0.5 min, and obtain a foamed body after cooling;

[0049] Perform primary foaming Place the foamed body in a closed mold cavity, heat the foamed body at a temperature of 130°C for...

Embodiment 3

[0057] The present embodiment provides a rigid PVC structural foam, which is mainly made of the following raw materials in parts by weight: 95 parts of PVC resin, 57 parts of isocyanate, 3.7 parts of supercritical fluid foaming agent and 2 parts of water vapor, the supercritical The fluid blowing agent is supercritical carbon dioxide.

[0058] This embodiment also provides a method for preparing the rigid PVC structural foam, which specifically includes the following steps:

[0059] Prepare the foam body: weigh PVC resin, isocyanate, supercritical carbon dioxide and water vapor according to the raw material ratio in the rigid PVC structural foam; heat the PVC resin to melt it, and add the The isocyanate is melted and kneaded for 0.5 min, and the foamed body is obtained after cooling; foaming is performed once: the foamed body is placed in a closed mold cavity, and the foamed body is heated to make it melt to form a cross The cross-linked melt is subjected to primary foaming a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell size | aaaaa | aaaaa |

| Cell size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com