Heat-conducting and flame-retardant V0 polypropylene material for storage battery of new-energy vehicle and preparation method

A technology for new energy vehicles and polypropylene materials, which is applied in the field of manufacturing new energy vehicle battery parts materials, can solve the problems of reduced density, no research and development, unable to meet the processing requirements of automobile battery shells, etc., and achieves simple operation and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A thermally conductive and flame-retardant V0 polypropylene material for a new energy vehicle battery, comprising the following raw materials in proportions by mass: 30-50 parts of polypropylene matrix, 15-25 parts of brominated flame retardant, and 5-5 parts of flame retardant synergist 8 parts, 15-30 parts of thermal conductive powder, 0.5-1 part of polytetrafluoroethylene, 0.5-1 part of antioxidant, 3-5 parts of compatibilizer, and 0.5-1 part of lubricant; among them, polypropylene The melt index of the matrix is 10-20g / min, which is available in the market; the brominated flame retardant is at least two of decabromodiphenylethane, octabromoether, and octabromos ether; the synergist of the flame retardant is di At least one of antimony and antimony pentoxide; heat conduction powder is at least two of magnesium oxide, aluminum oxide, zinc oxide, silicon dioxide, calcined magnesium oxide, calcined aluminum oxide, and light magnesium oxide; polytetrafluoroethylene The...

Embodiment 2

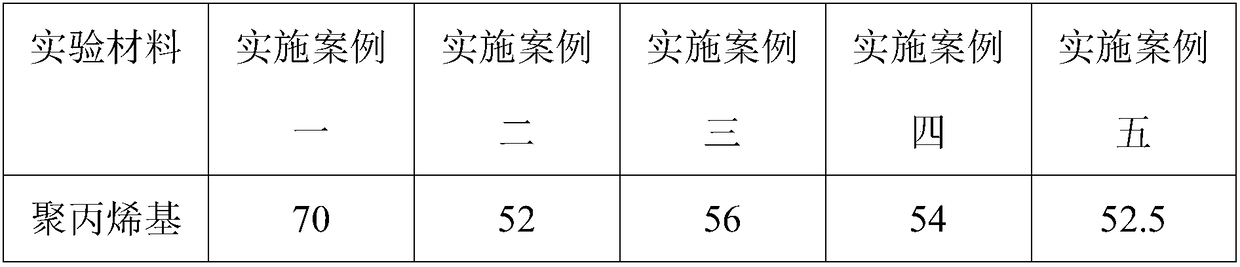

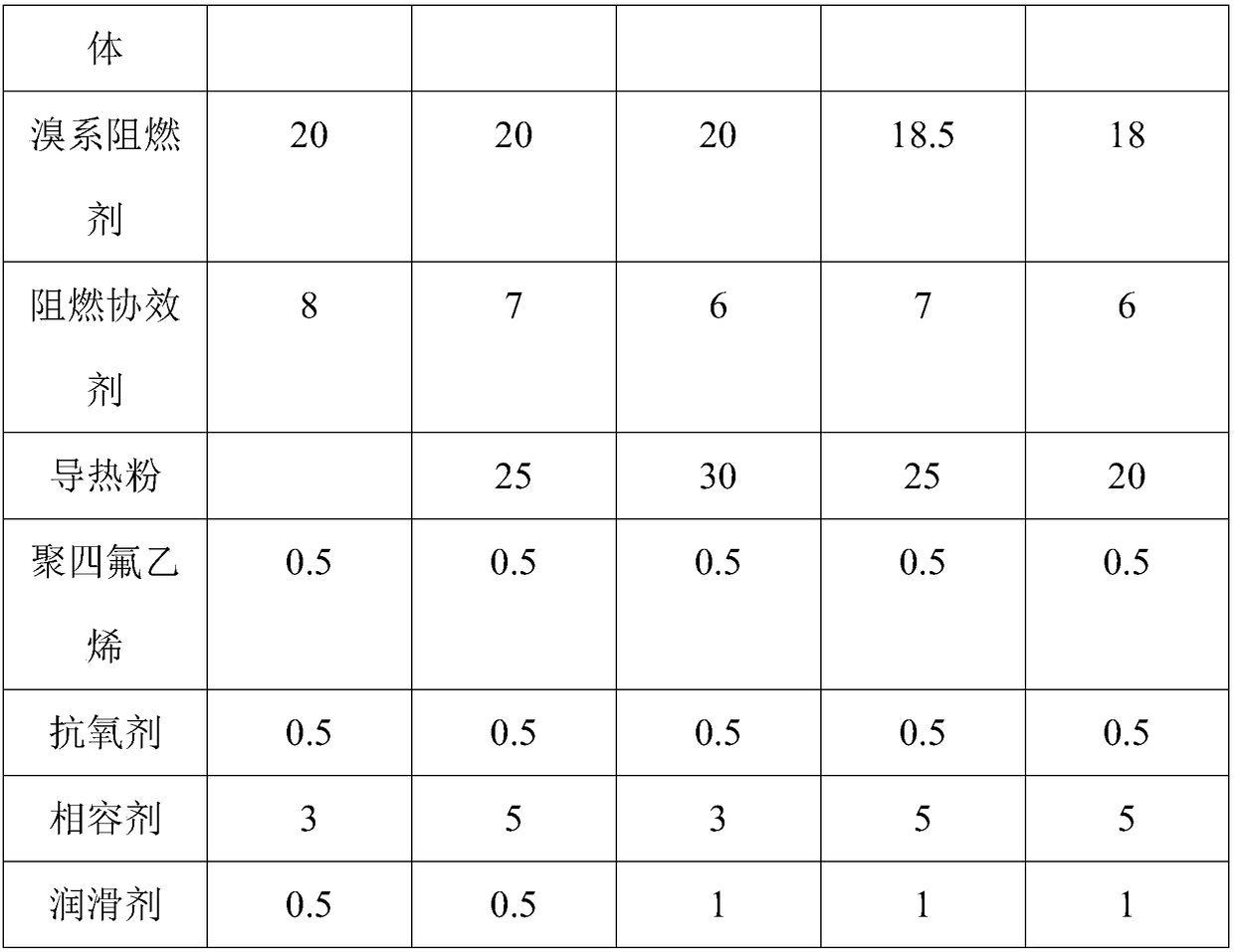

[0029] Based on the description of Example 1, and for the material formula provided in Example 1, this example provides the following comparative examples of implementation of different parts of raw materials:

[0030]

[0031]

[0032] Add the raw material ratio of the above different implementation cases into the high-speed mixer and mix evenly. The temperature of the high-speed mixer is controlled at 80-100°C, the speed is controlled at 1700-1900r / min, and the mixing time is controlled at 3-5min. The obtained mixture is fed into the main feed of the twin-screw extruder, and the extrusion temperature is controlled between 180-200°C.

[0033]

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com