Method for synthesizing sulfonyl-substituted pyran type compound

A sulfonyl and compound technology, applied in the field of organic synthesis and catalysis, can solve the problems of high reaction cost, harsh reaction conditions, long reaction time, etc., and achieve the effects of simple and convenient operation, low price and single product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 45.6 mg (0.24 mmol) of p-toluenesulfonyl chloride, Ir(dtbbpy)(ppy) 2 PF 6 2.0 mg (0.002 mmol) was put into a reaction flask, added to 2 mL of acetonitrile solution, and 3-((3-methylbut-2-en-1-yl)oxy)prop-1-yn-1 was measured. - base) benzene 42.3 ul (0.20 mmol), water 36 ul (2.00 mmol), in N 2 Placed under the condition of 23 W fluorescent lamp under the irradiation of room temperature stirring reaction, TLC detected the progress of the reaction, after about 24h, the detection reaction was complete, separated and purified (petroleum ether: ethyl acetate=20:1) by column chromatography to obtain a white solid, record As product 1, yield: 87%.

[0019] The structural characterization of product 1 is as follows:

[0020]

[0021] white solid; melting point: 124 - 126 o C; 1 H NMR (400 MHz, CDCl 3 ) δ 7.53–7.39 (m, 1H), 7.26 ( J = 8.0 Hz, 2H), 7.13 ( J = 8.0 Hz, 3H), 7.01 ( J = 8.0 Hz, 2H), 6.47(brs, 1H), 4.83 (d, J = 17.6 Hz, 1H), 4.68 (d, J = 12.0 ...

Embodiment 2

[0047] Using the same method and reaction conditions of Example 1, when 3-methyl-1-(propyl-2-ynyl-1-oxyl)-2-butene is a different substituent, the following different target products are obtained .

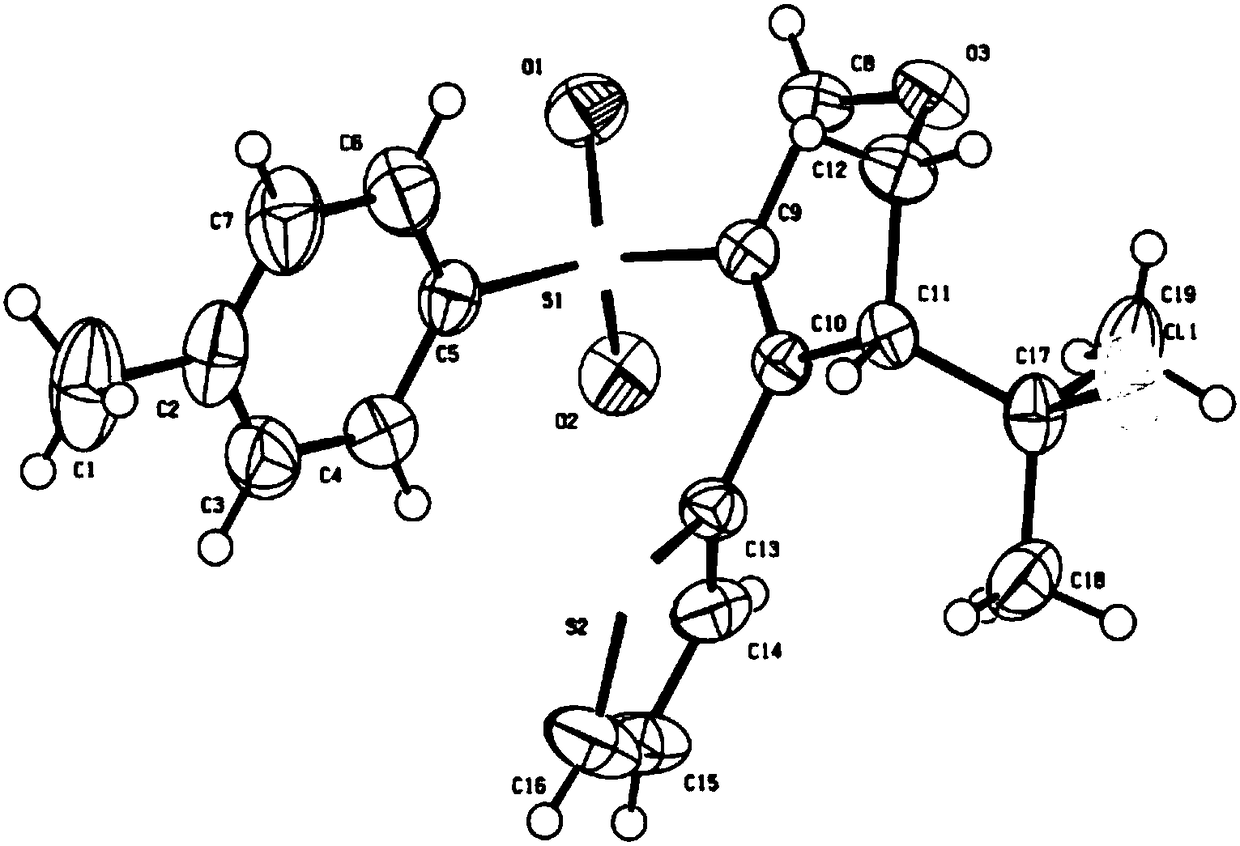

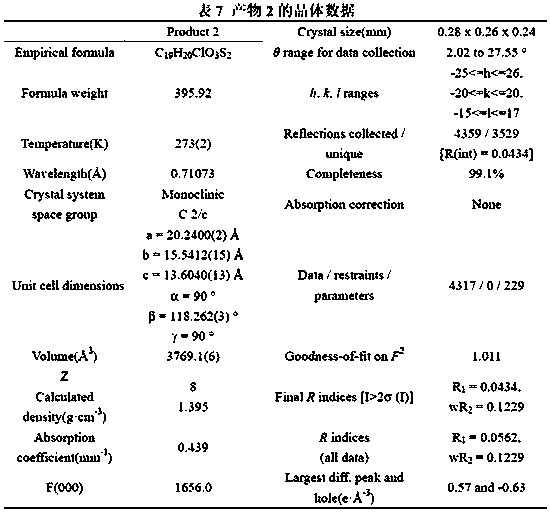

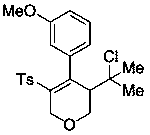

[0048] The structure of product 2 is characterized as follows:

[0049]

[0050] Reddish-brown solid; melting point: 164 - 166 o C; 1 H NMR (400 MHz, CDCl 3 ) δ 7.26 (dd, J =8.7, 3.4 Hz, 2H), 7.22 (d, J = 8.2 Hz, 2H), 7.05 (d, J = 8.0 Hz, 2H), 6.96–6.91 (m, 1H), 4.84 (d, J = 18.1 Hz, 1H), 4.69–4.52 (m, 2H), 3.51 (dd, J =12.0, 3.1 Hz, 1H), 2.59 (s, 1H), 2.33 (s, 3H), 1.63 (s, 4H), 1.28 (s, 3H); 13 CNMR (CDCl 3 , 150 MHz): 143.8, 143.2, 140.1, 139.0, 137.2, 132.2, 129.0, 128.2, 127.2, 126.7, 73.8, 66.7, 66.4, 54.6, 33.4, 30.6, 21.56; IR (neat) n = 2927,1605, 1460, 1383, 1307, 1149, 1092, 846, 805, 717cm -1 ; HRMS (ESI) theoretically calculated value [C 19 H 21 S 2 O 3 ClNa] + [M+Na] + : 419.0518, actual measured value: 419.0528, in order to further determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com