Method for controlling anaerobic ammonia oxidized granular sludge in high-load reactor to float

An anammox and granular sludge technology, which is applied in the control of anammox granular sludge floating in high-load reactors and anammox denitrification fields, can solve the problems of being subject to various restrictions, complicated operations and engineering problems. To solve the problems of large quantity, etc., to achieve the effect of strong applicability, simple operation process, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Effects of signal molecule type and concentration on the settling performance and activity of anammox granular sludge in a high-load reactor

[0040] Four groups of UASB reactors were set up, respectively for the groups without adding signal molecules (R 1 ), C8-HSL group (R 2 ), C6-HSL group (R 3 ), C12-HSL group (R 4 ). Among them, adding C8-HSL group (R 2 ), adding C6-HSL group (R 3 ) and adding C12-HSL group (R 4 ), four parallel UASB reactors were set up in each group, and the dosing concentration of signal molecules in the influent water of each reactor was set to 0.5mg / L, 5mg / L, 15mg / L and 30mg / L respectively. Among them, the four parallel UASB reactors in each group of C8-HSL group, C6-HSL group and C12-HSL group are numbered R according to the signal molecule dosage concentration from small to large. 2-1 , R 2-2 , R 2-3 , R 2-4 , R 3-1 , R 3-2 , R 3-3 , R 3-4 , R 4-1 , R 4-2 , R 4-3 , R 4-4 .

[0041] The same amount of inoculated sludge was ...

Embodiment 2

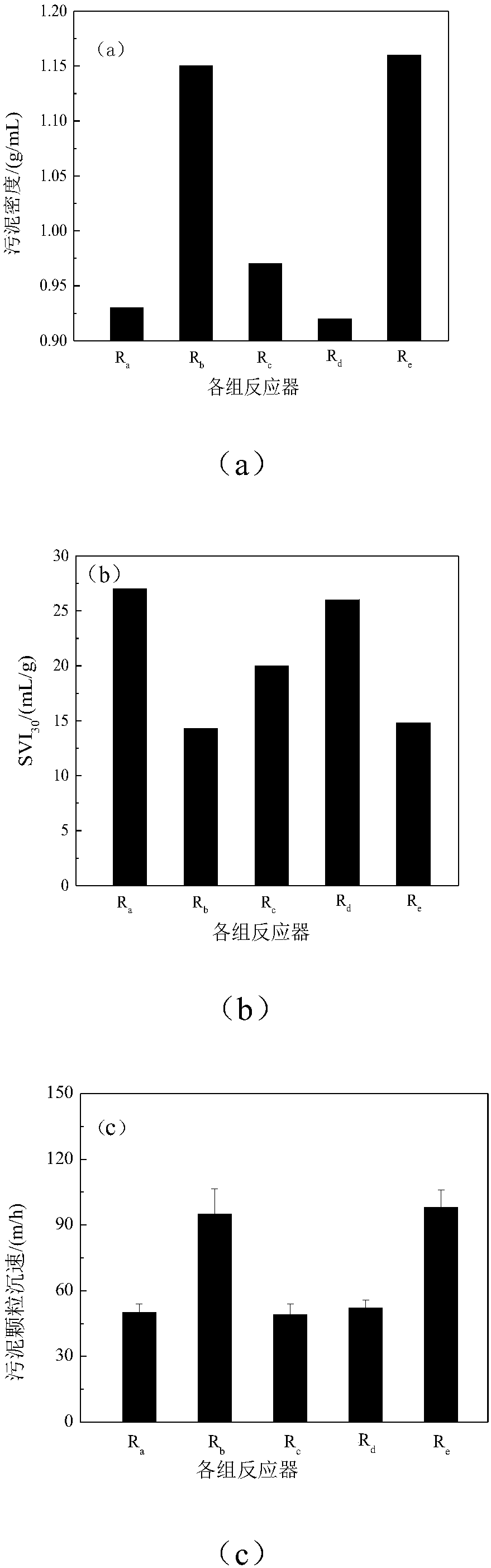

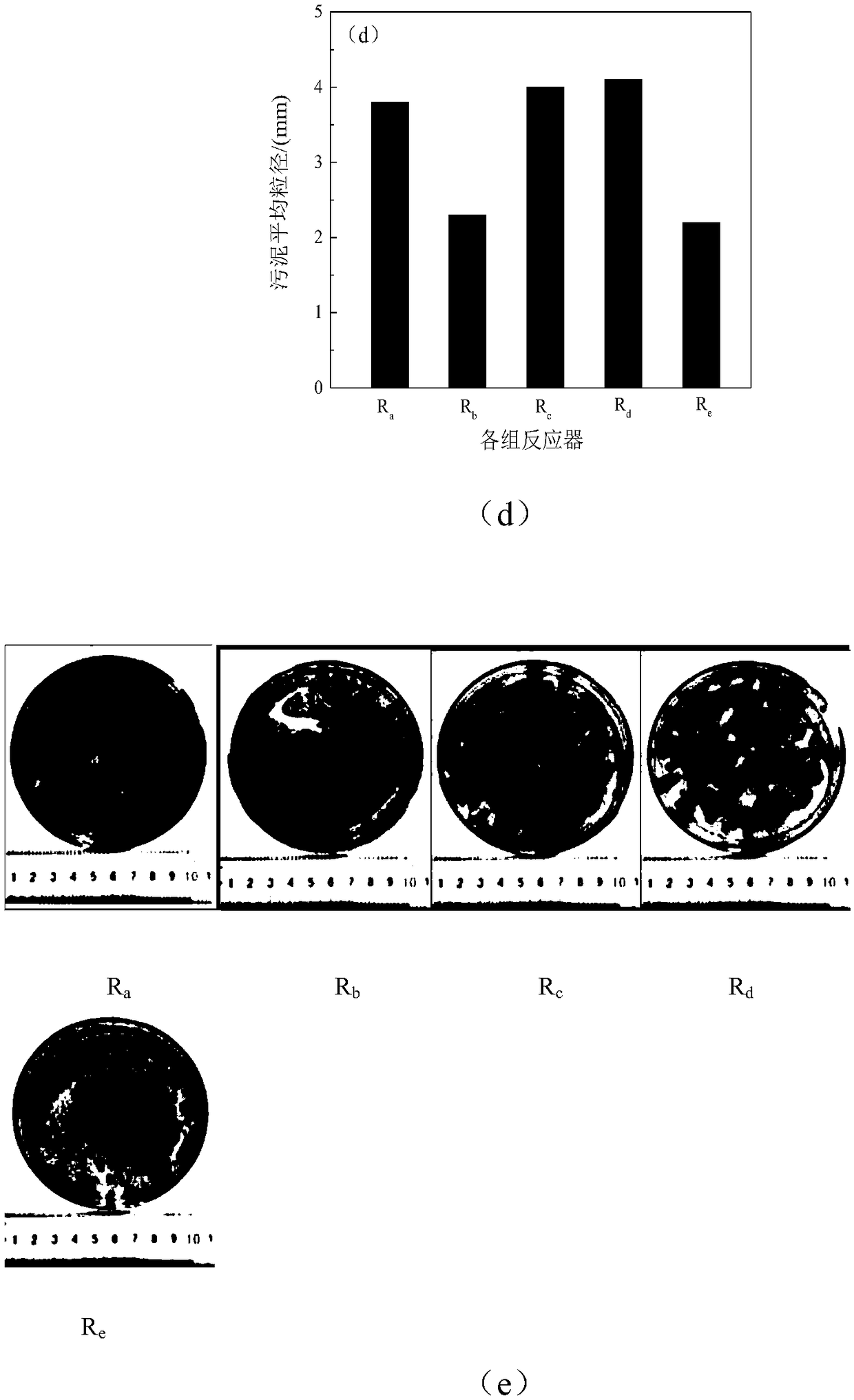

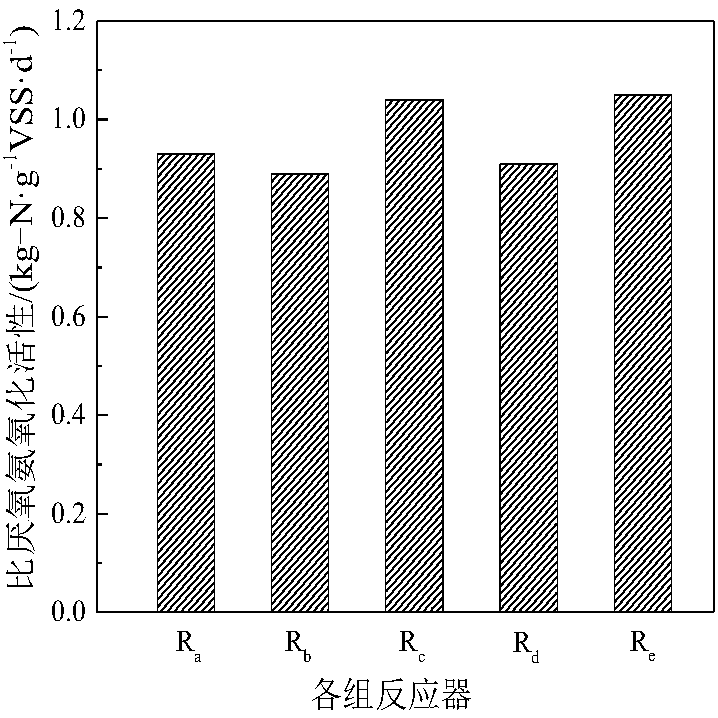

[0044] Example 2: Effects of Signal Molecule Mixed Solution on Settling Performance and Activity of Anammox Granular Sludge in High Load Reactor

[0045] Example 1 optimizes the type of signal molecule that can effectively control the floating of granular sludge as C8-HSL, and its optimal dosage concentration is 5mg / L; the type of signal molecule that can effectively improve the activity of granular sludge is C6-HSL, and its The optimum dosage concentration is 15mg / L. C8-HSL and C6-HSL mixed solution group (R e ), R e The concentrations of C8-HSL and C6-HSL were 5mg / L and 15mg / L, respectively. Set the group without adding signal molecules (R a ), adding 5mg / L C8-HSL group (R b ), adding 15mg / L C6-HSL group (R c ), adding 30mg / L C12-HSL group (R d ). The operation and operating conditions of each group of reactors are the same as in Example 1. At the end of the high-load operating phase, the R a , R b , R c , R d and R e Take an appropriate amount of granular sludge ...

Embodiment 3

[0047] Mechanism of different types of signaling molecules affecting the settling performance of anaerobic ammonium oxidation granular sludge in a high-load reactor

[0048] In order to explore the mechanism by which different types of signal molecules affect the settling performance of anammox granular sludge in high-load reactors, the reactor R was analyzed at the end of the high-load phase in Example 2. a , R b , R c , R d and R e EPS components and content, PN / PS value and surface hydrophobicity of medium granular sludge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com