Efficient and economical simultaneous removal of nitrate nitrogen and ammonia nitrogen bioreactor

A bioreactor and economical technology, applied in the field of bioreactors for the simultaneous removal of nitrate nitrogen and ammonia nitrogen, can solve the problems of high energy consumption for oxygenation, low volumetric denitrification efficiency, large oxygen demand, etc., and achieve the effect of optimizing the habitat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

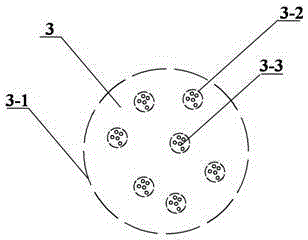

[0021] Such as figure 1 , 2 As shown, the efficient and economical bioreactor for simultaneous removal of nitrate nitrogen and ammonia nitrogen includes water distribution area A, short-range denitrification area B, anammox area C and separation area D from bottom to top; water distribution area A from bottom to There are sludge discharge pipe 1 and return-water inlet pipe 2 in sequence, the short-range denitrification zone B is directly connected to the top of the water distribution zone A, and a transverse partition is provided between the upper end of the short-range denitrification zone B and the bottom of the anammox zone C 6 and connected by a flange, another transverse partition 6 is provided between the upper end of the anammox zone C and the bottom of the separation zone D, and is connected by another flange, and mud guide pipes are respectively arranged on the two transverse partitions 6 4. The catheter 7, the upper part of the short-range denitrification zone B and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com