Single-stage multi-effect evaporation and separation device

A multi-effect evaporation and separation device technology, applied in the direction of centrifugal separation water/sewage treatment, water/sludge/sewage treatment, water/sewage treatment, etc. Reduce the equipment investment and operating costs, overcome the single working state, and improve the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

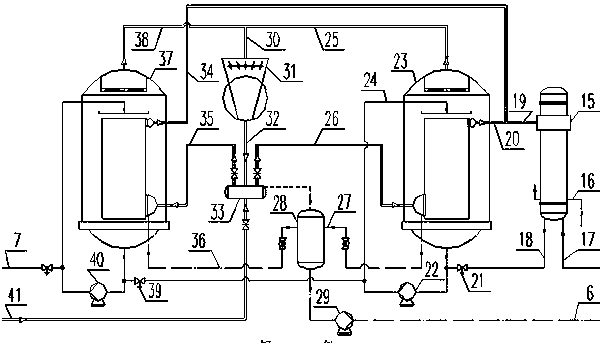

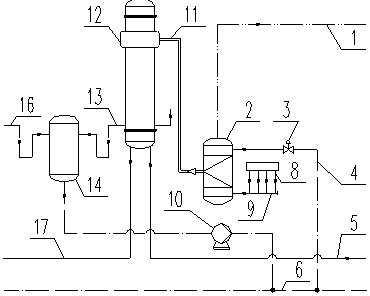

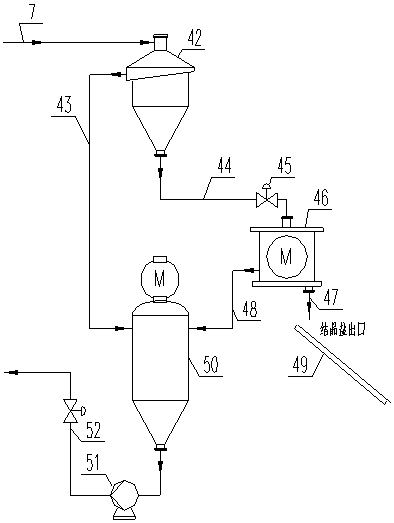

[0019] The present invention is explained below with reference to the embodiments given in the accompanying drawings.

[0020] It can be seen from the embodiments given in the accompanying drawings that the present invention includes a first evaporator 23 and a second evaporator 37 . The first evaporator 23 and the second evaporator 37 are respectively provided with a communication pipeline with a first circulation pump 22 and a second circulation pump 40 on the evaporated liquid output end and the evaporated liquid input end. The liquid outlet pipe 18 of the surface condenser 15 is communicated with the outlet pipe 18 of the surface condenser 15 at the upstream of the first circulation pump 22 . The downstream of the first circulation pump 22 is connected with the upstream of the second circulation pump 40 by a pipeline with a feed control valve 39 of the second evaporator 37 thereon. The output pipes 25 and 38 of the secondary steam pipes of the two evaporators communicate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com