High salt gas field water evaporation crystallization treatment device

An evaporation crystallization and treatment device technology, which is applied in the field of water evaporation crystallization treatment devices in high-salt gas fields, can solve the problems of complex components of produced water, many maintenance personnel, ecological damage, etc., achieve reasonable cascade utilization of heat energy, eliminate steam overheating, prevent The effect of high temperature damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

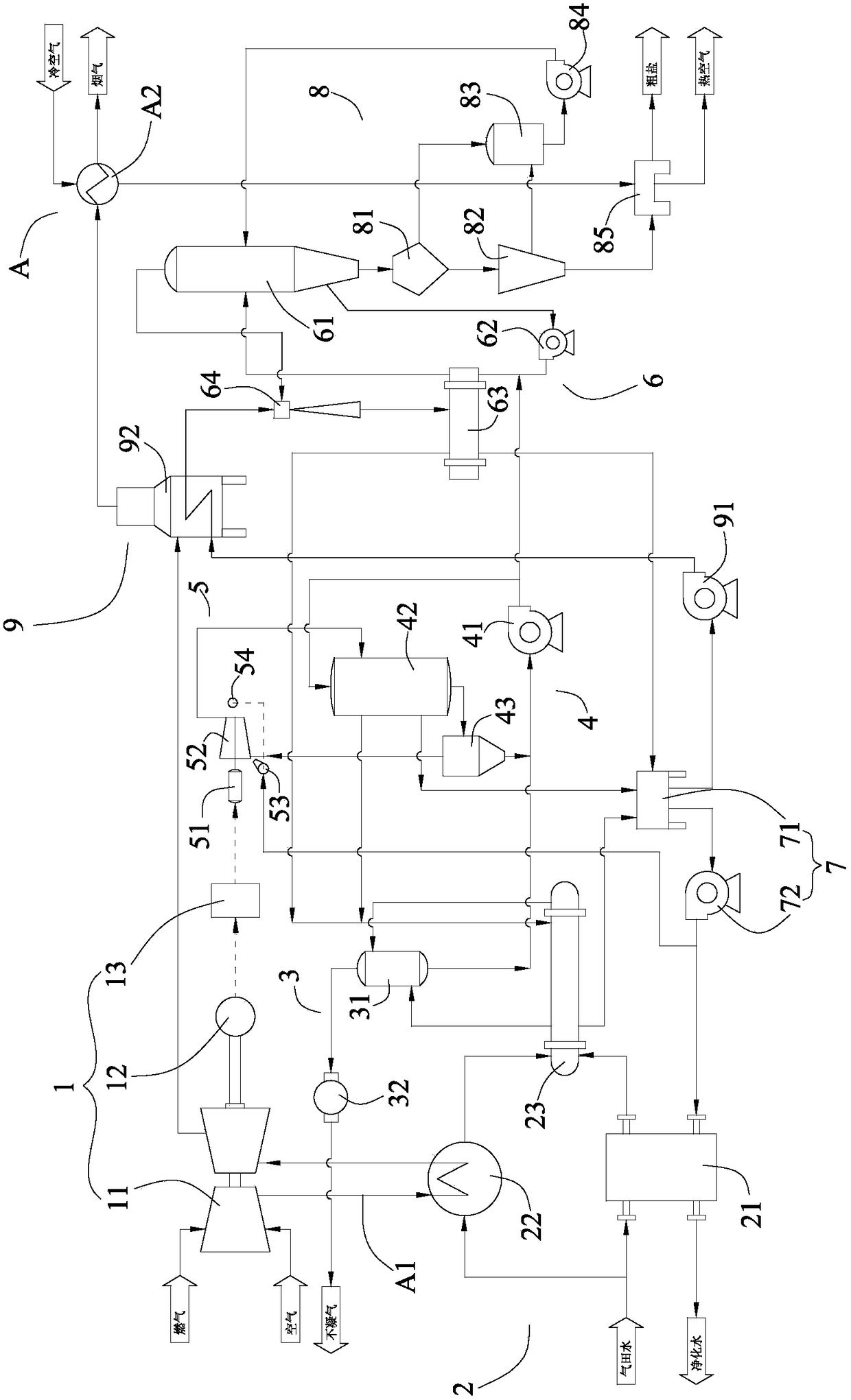

[0040] The high-salt gas field water evaporation and crystallization treatment device of the present invention will be described in detail below with reference to the accompanying drawings.

[0041] refer to figure 1 According to the present invention, the high-salt gas field water evaporation crystallization treatment device includes a power system 1, a preheating system 2, a degassing system 3, an evaporation condensation system 4, a vapor compression system 5, an evaporation crystallization system 6, and a condensed water recycling system 7. Crystallization salt production system 8, steam generation system 9 and waste heat recovery system A.

[0042] The power system 1 includes a gas engine 11, a generator 12, and a power supply and distribution mechanism 13; external gas and air enter the gas engine 11 for combustion and generate high-temperature flue gas, and the high-temperature flue gas enters the steam generation system 9; the gas engine 11 works and drives The genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com