Washing resistant metal material

A metal material, water-resistant technology, applied in the direction of metal layered products, coatings, layered products, etc., can solve problems such as poor water-washing resistance, and achieve the effect of not easy to fall off, stable performance, and good bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

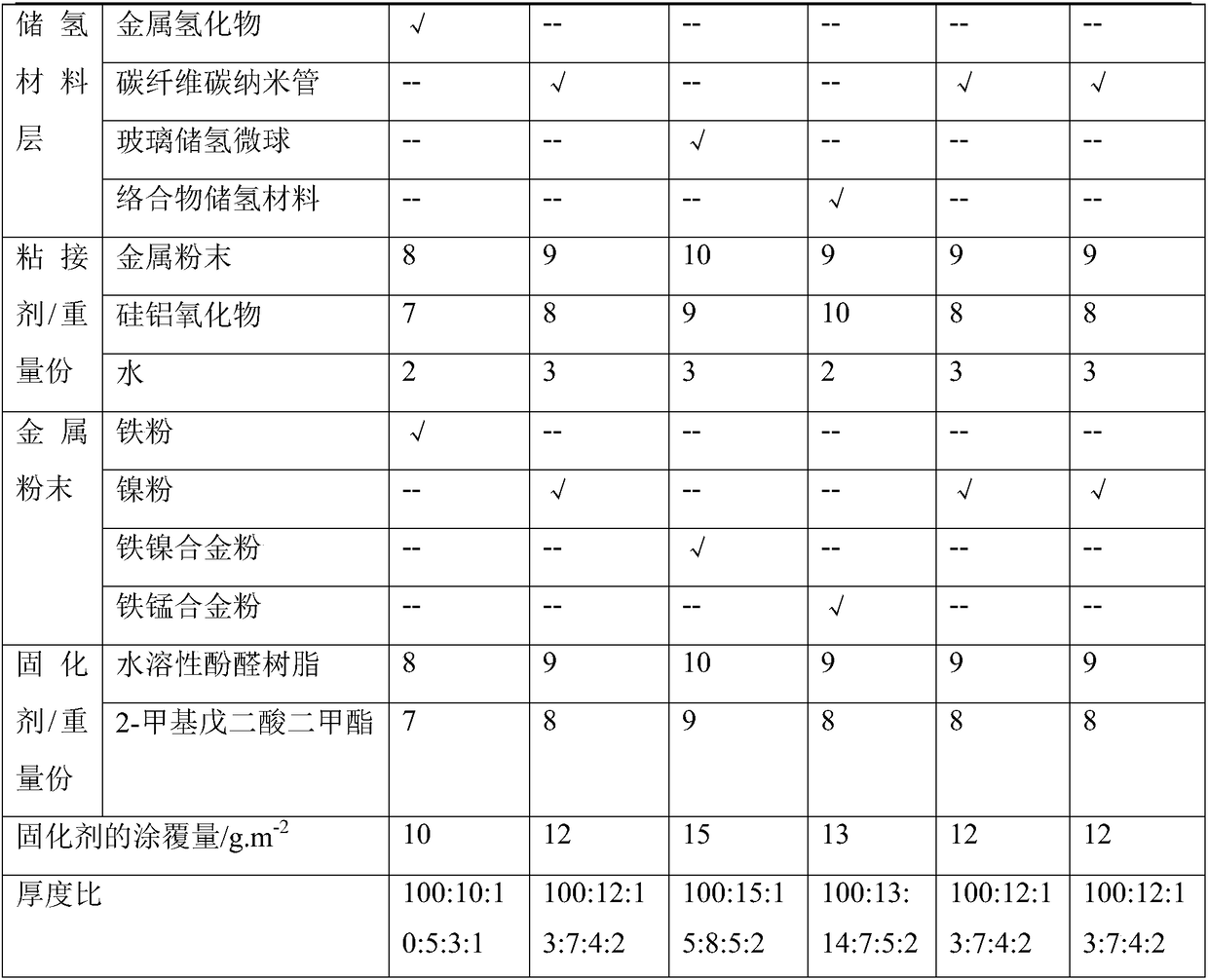

[0037] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

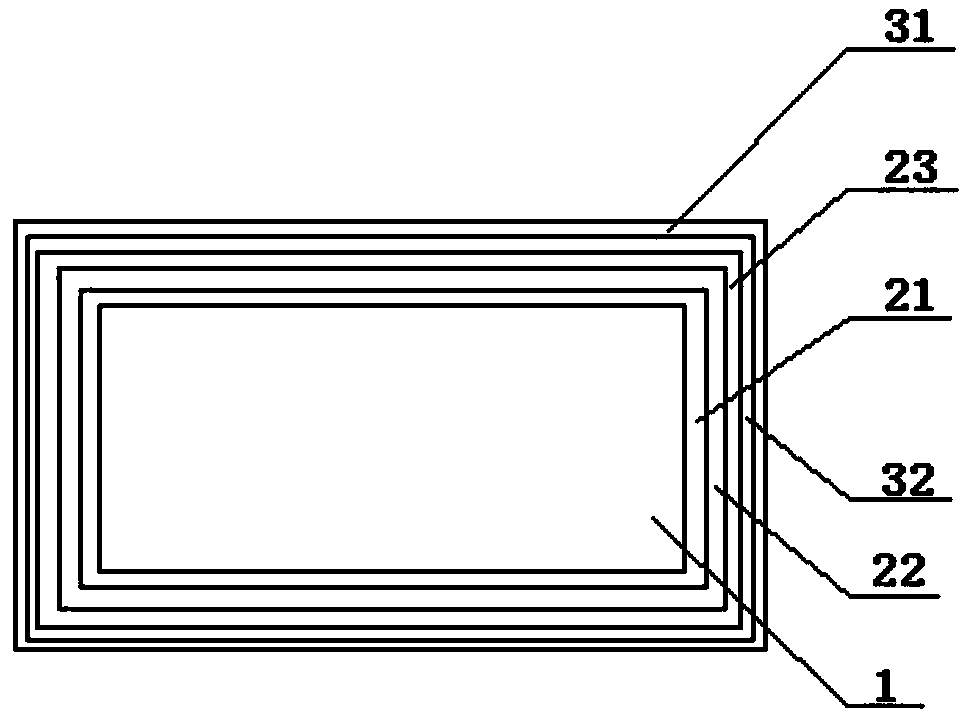

[0038] A washable metal material, the washable metal includes an underlying metal 1 and a composite layer metal 2, and the washable metal also includes an anti-corrosion layer 3;

[0039] The composite layer metal 2 is formed by sequentially bonding a magnetic alloy layer 21, a fiber metal layer 22 and a hydrogen storage material layer 23;

[0040] The magnetic alloy layer 21 is bonded to the underlying metal 1 as a whole;

[0041] The anti-corrosion layer 3 is composed of a cured layer 31 and a polytetrafluoroethylene layer 32;

[0042] The cured layer 31 and the hydrogen storage material layer 23 are connected as a whole through a curing agent.

[0043] Specifically, the magnetic alloy layer 21 is a neodymium iron boron magnet; the fiber metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com