Lifting adjustable wood sliding table saw with synchronous saw dust suction function

A technology for pushing table saws and chips, which is applied to wood processing appliances, sawing components, sawing equipment, etc., can solve the problems of affecting work efficiency, high labor intensity, and the operator's operating speed drop, etc. The effect of improving suction efficiency and ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

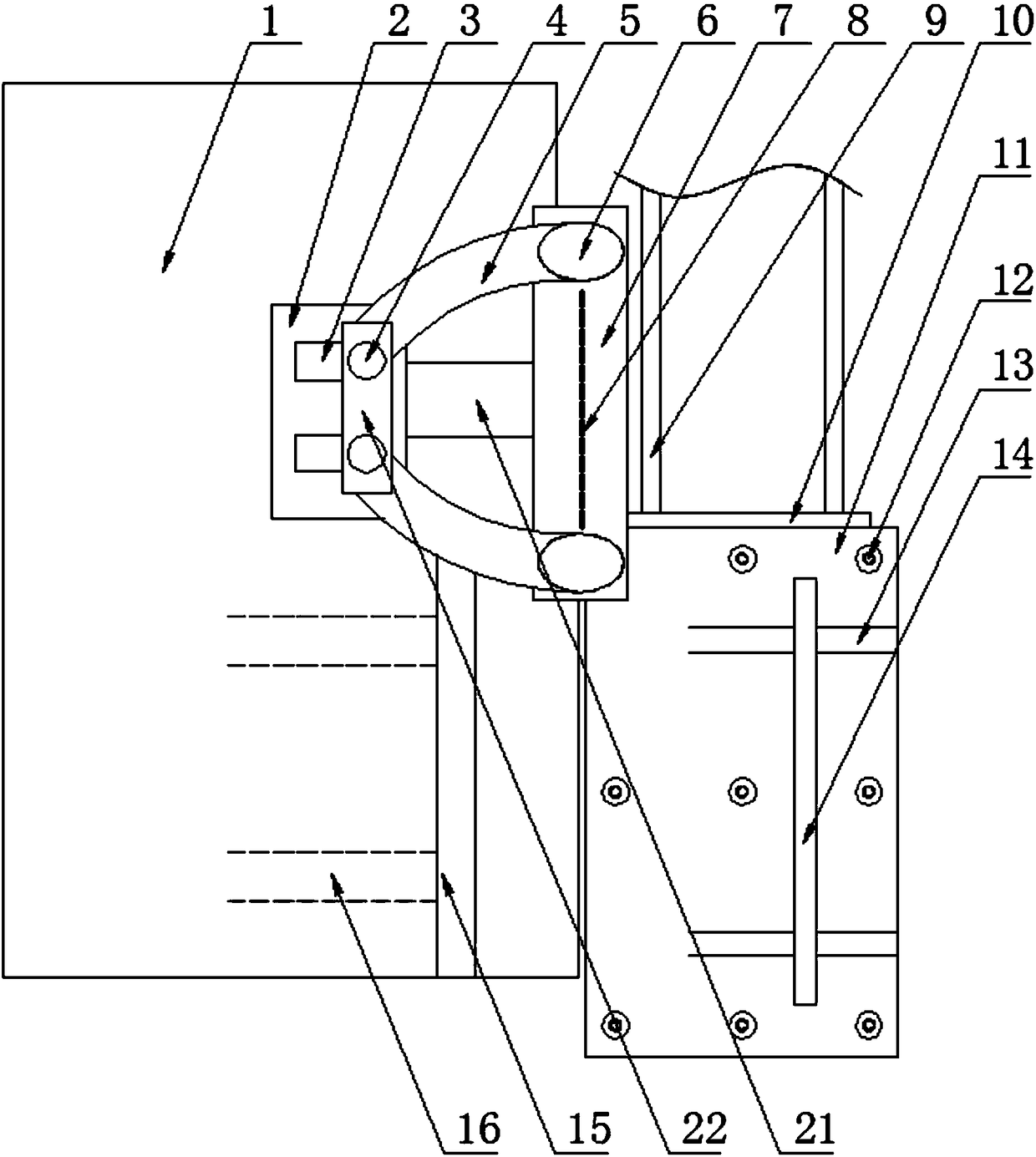

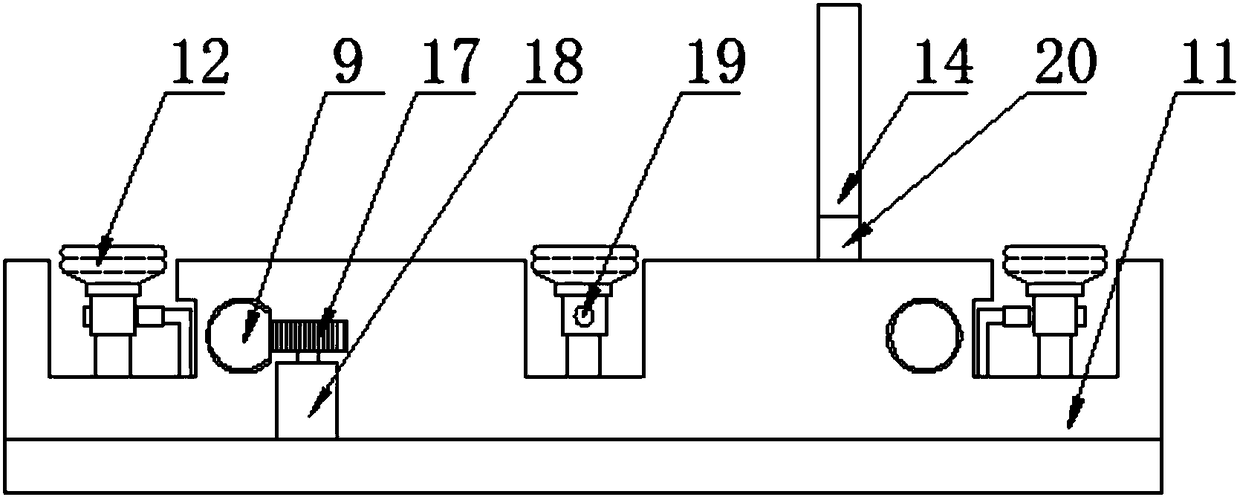

[0018] A sliding table saw with adjustable lifting and synchronous suction of chips, including a fixed table 1, a sliding table 11, and a cutting saw 8, the cutting saw is arranged between the fixed table and the sliding table, and a wood material is arranged above the cutting saw. Chips recovery cover 7, one side of the wood chips recovery cover is slidingly connected with the lifting platform 2 through the lifting arm 21, and the front and rear ends of the wood chips recovery cover top are respectively shaped with suction holes 6, and the suction holes pass through the suction holes respectively. The air duct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com