High-performance intelligent three-phase minimum quantity lubrication system and use method thereof

A micro-lubrication, high-performance technology, used in metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problems of low degree of intelligence, inaccurate adjustment, high noise, etc., to improve the level of intelligence , The effect of simple programming and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

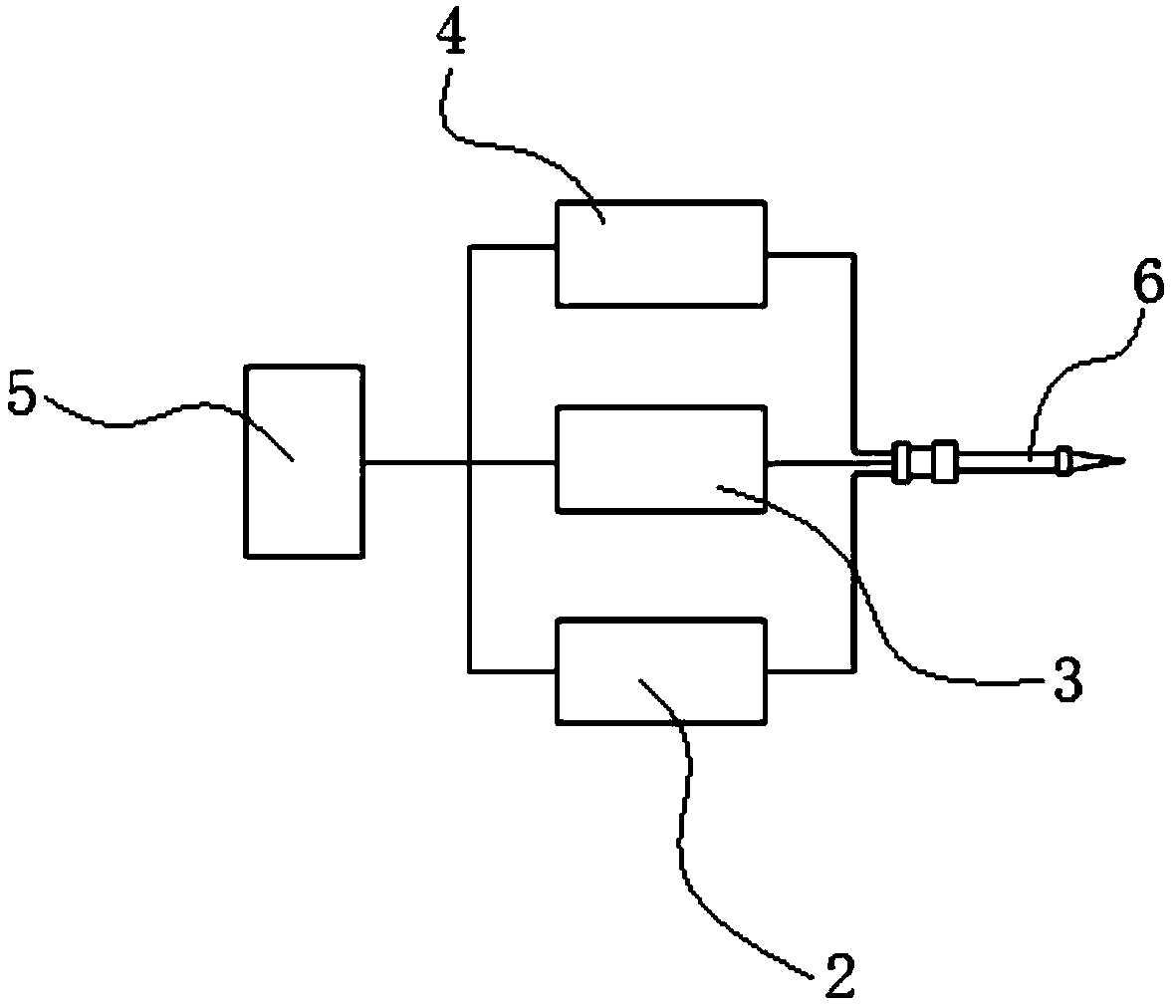

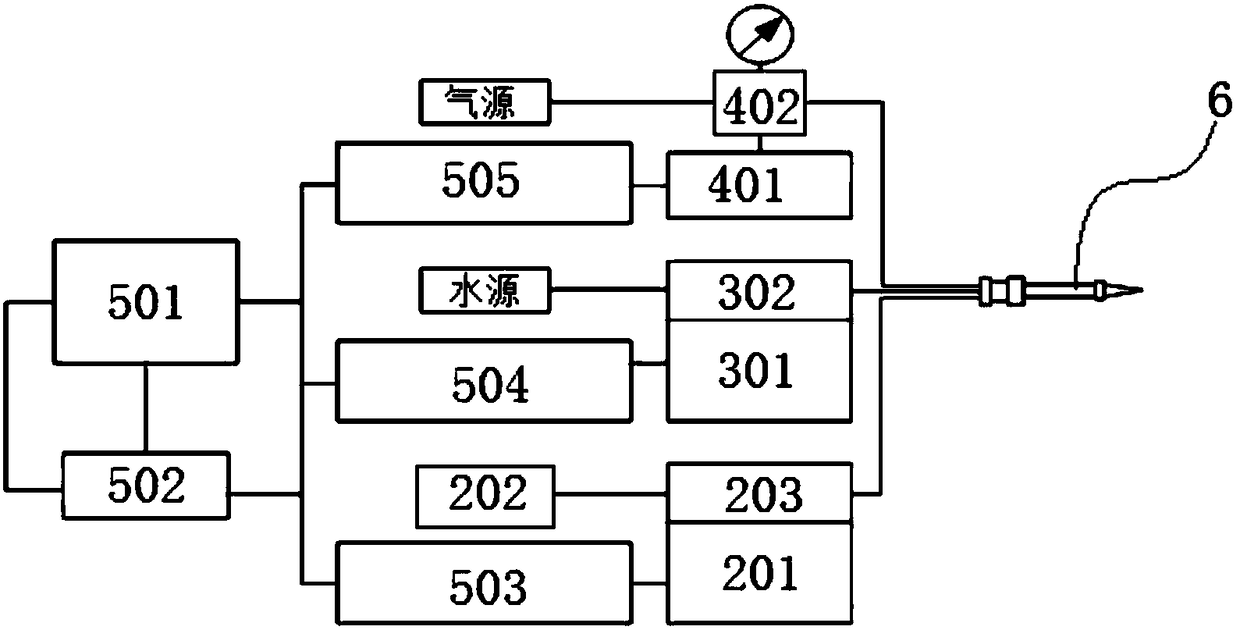

[0041] See figure 1 , figure 2 with Figure 5 , This embodiment discloses a high-performance intelligent three-phase micro-lubrication system, including a housing 1, a micro-lubricating oil digital quantitative supply unit 2, a water digital quantitative supply unit 3 connected with an external water source, and a compressed gas supply connected with a gas source Unit 4, intelligent control unit 5 and injection unit 6.

[0042] See Image 6 The spray unit 6 includes a spray unit base 604, a universal joint tube 605 and a nozzle 606. The injection unit base 604, the universal joint pipe 605 and the nozzle 606 are connected in sequence as a whole. The injection unit base 604 is provided with a compressed gas inlet 601, a trace lubricant inlet 602 and a water inlet 603.

[0043] See Figure 5 The micro-lubricating oil digital quantitative supply unit 2 includes a stepping motor I201, an oil cup 202 and a peristaltic pump I203. The stepping motor I201 is connected to the peristaltic...

Embodiment 2

[0067] This embodiment discloses a method for using the high-performance intelligent three-phase micro-lubrication system described in embodiment 1, see Picture 9 , Including the following steps:

[0068] 1) The system power is turned on. Connect the three-pin plug to 220 AC, turn the rocker switch to the on position, the power indicator 507 will be on, and the system will enter the standby state.

[0069] 2) System hardware settings. Set the current value and subdivision switch of driver I503, driver II504 and driver III505 to the position that matches the respective stepper motors. Taking into account the inaccurate movement of the stepper motor due to resistance, after using the high-performance intelligent three-phase micro-lubrication system for a period of time, you can manually adjust the pressure regulator knob of the pressure regulator filter to the closed position after the power is turned off, and wait for the system to work It will be automatically set to zero to el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com