Automatic powder grinding device in anhydrous drying oven

A technology of grinding device and drying box, which is applied in the field of automatic powder grinding device and anhydrous automatic powder grinding device, which can solve the problems of difficult removal and strong infrared absorption peak, achieve compact structure of the device, improve grinding efficiency, avoid low efficiency and uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

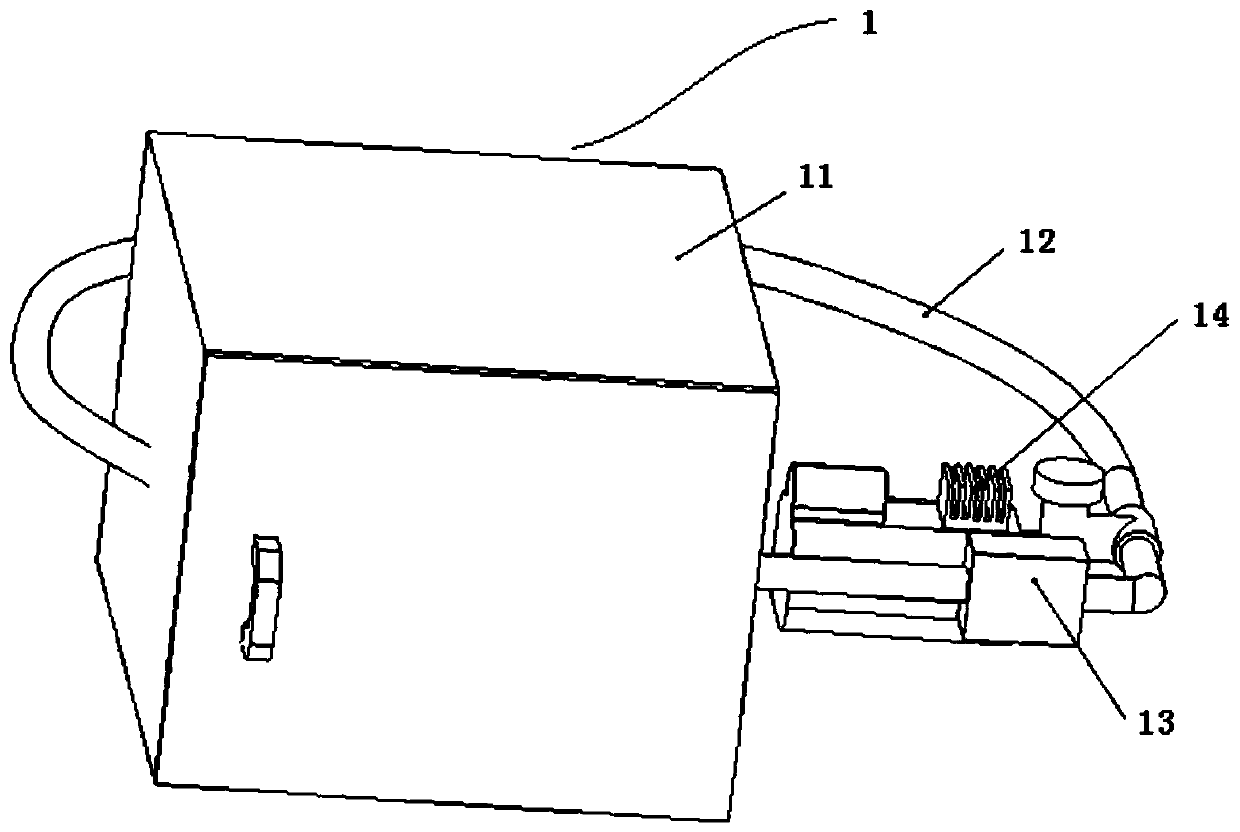

[0023] Such as figure 1 , figure 2 As shown, the present invention provides an automatic powder grinding device in an anhydrous drying box, which includes a drying mechanism 1 and an automatic powder grinding mechanism 2;

[0024] Wherein, drying mechanism 1 comprises box body 11, circulation line 12, gas dryer 13 and vacuum pump 14, and circulation line 12 is arranged on the outside of box body 11, is provided with gas dryer 13 and vacuum pump 14 on it, and circulation line Both ends of 12 are connected with the inside of the box body 11 to form a dry circulation gas path for the gas inside the box body 11 to ensure the dryness of the gas inside the box body 11;

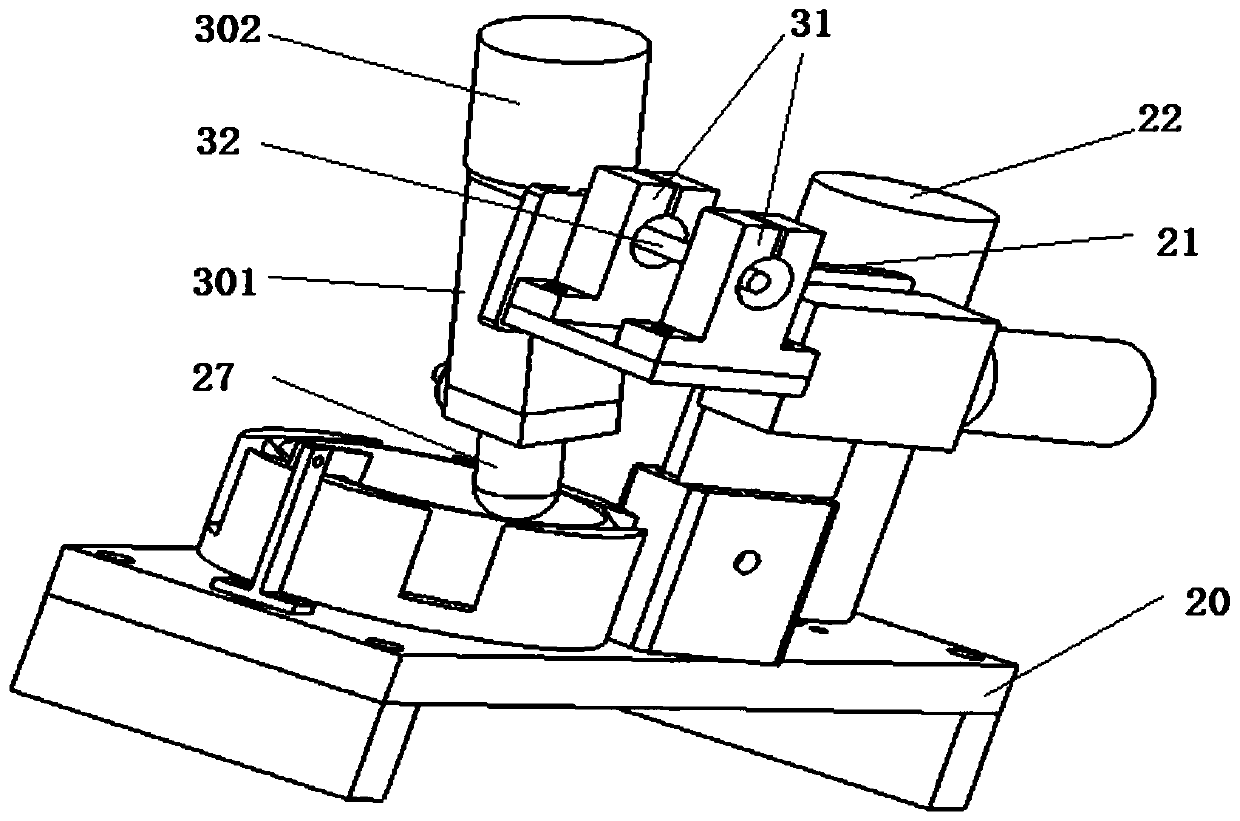

[0025] The automatic powder grinding mechanism 2 is placed in the box body 11, and the automatic powder grinding mechanism 2 includes a base 20, a frame 21, a rotating drive device 22, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com