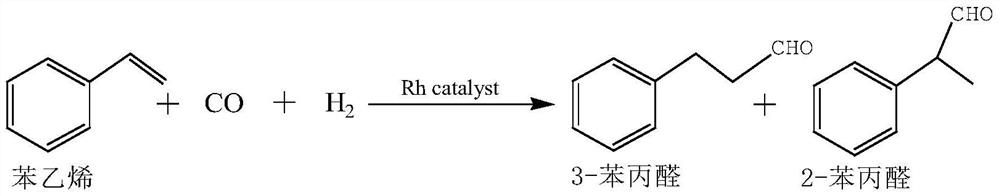

A kind of supported rhodium liquid metal solution catalyst and its preparation and application

A technology of liquid metal and catalyst, applied in the field of rhodium-loaded liquid metal solution catalyst and its preparation and application, can solve the problems of poor selectivity, poor stability, low reactivity, etc., achieve high selectivity, simple preparation method, high Active and Selective Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

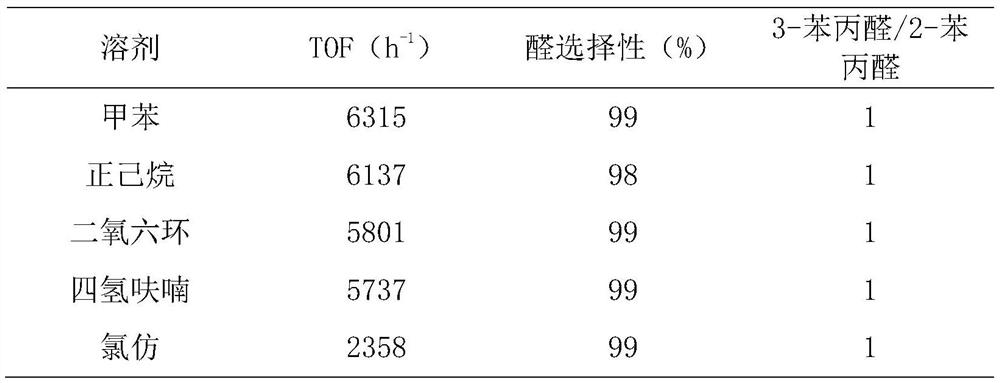

Method used

Image

Examples

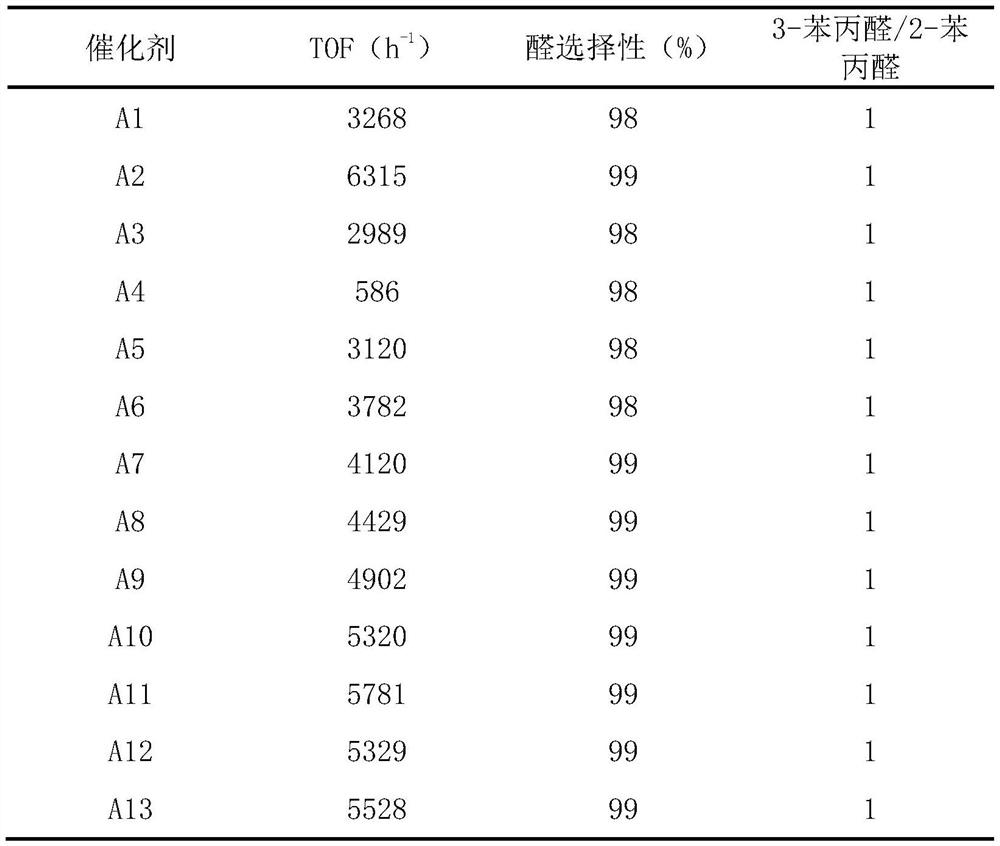

Embodiment example 1

[0023] First dissolve 6.5mg rhodium acetate (3mg rhodium) in 25ml of n-hexane, then add 1340mg gallium, 410mg indium, 250mg tin (ratio of gallium indium tin is 1:0.31:0.0.19), seal and store at 60°C Heat and stir in an oil bath for 8 hours, wait to cool to room temperature, add 8000 mg of silica gel (ratio of rhodium, gallium indium tin and silica gel is 1:667:2667), stir for 3 hours, then filter, rinse with a large amount of n-hexane, and finally in 40 The catalyst A1 (the mass of Rh accounted for about 0.03% of the total mass) was dried overnight under vacuum condition at °C.

Embodiment example 2

[0025] Dissolve 21.7mg of rhodium acetate (10mg of rhodium) in 25ml of n-hexane, then add 1340mg of gallium, 410mg of indium, and 250mg of tin (the ratio of gallium to indium tin is 1:0.31:0.19), seal it, and put it in an oil bath at 80°C Heat and stir in the pot for 10 hours. After cooling to room temperature, add 8000 mg of silica gel (the ratio of rhodium, gallium indium tin and silica gel is 1:200:800), stir for 4 hours, then filter, wash with a large amount of n-hexane, and finally vacuum at 60 ° C. Dry overnight under conditions to obtain catalyst A2 (the mass of Rh accounts for about 0.1% of the total mass).

Embodiment example 3

[0027] First dissolve 51.3mg rhodium trichloride (trihydrate) (20mg rhodium) in 80ml of toluene, then add 1666mg gallium, 167mg indium, 167mg tin (the ratio of gallium indium tin is 1:0.1:0.1), seal, and Heat and stir in an oil bath at 100°C for 12 hours. After cooling to room temperature, add 8000 mg of silica gel (the ratio of rhodium, gallium indium tin, and silica gel is 1:100:400), stir for 5 hours, then filter, rinse with a large amount of toluene, and finally Dry overnight at 80° C. under vacuum to obtain catalyst A3 (the mass of Rh accounts for about 0.2% of the total mass).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com