Hydrophilic modification method of polytetrafluoroethylene porous membrane

A polytetrafluoroethylene, hydrophilic modification technology, applied in the field of hydrophilic modification of porous membrane surface, can solve the problem of limited hydrophilic performance, and achieve good hydrophilicity, long-lasting hydrophilicity, and good anti-pollution property. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

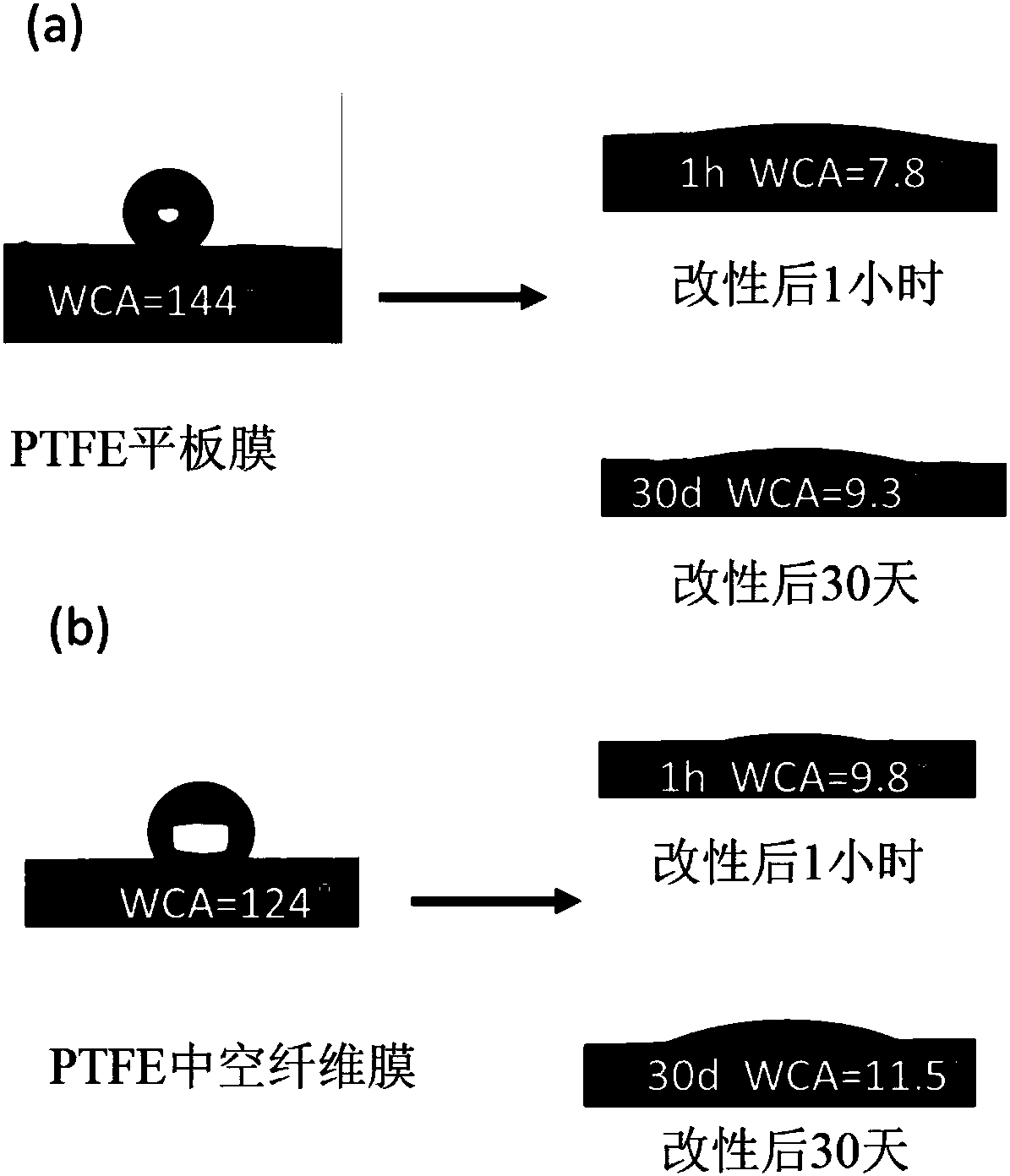

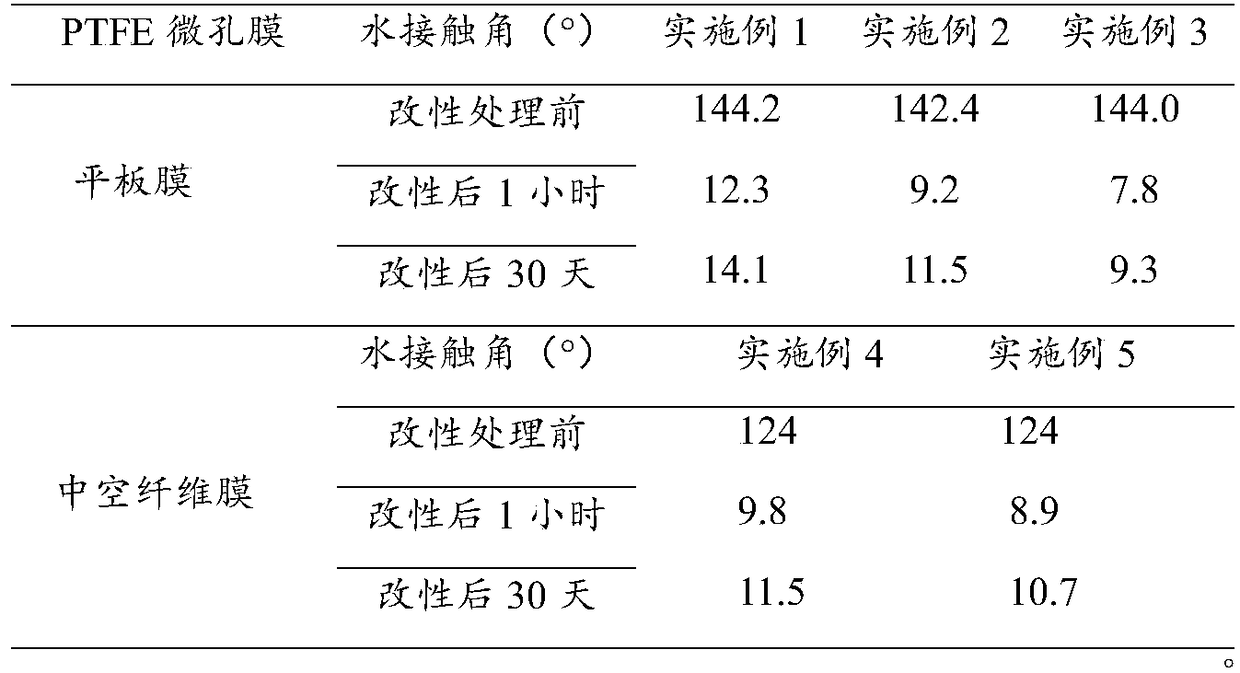

[0016] 1) Firstly, fully wash the flat polytetrafluoroethylene porous membrane with ethanol to remove impurities on the surface of the membrane, and then perform corona treatment after drying. The treatment power is 1000W and the time is 150S;

[0017] 2) Place the PTFE membrane treated in step (1) in polyethyleneimine solution containing N-(2-perfluorooctylsulfonamidoethyl)-β,β'-iminodipropionic acid disodium amino acid Among them, N-(2-perfluorooctylsulfonamidoethyl)-β,β'-iminodipropionate disodium amino acid concentration is 0.6wt%, polyethyleneimine concentration is 3wt%, impregnation reaction After 20 minutes, the membrane was taken out, cleaned with a large amount of deionized water, and vacuum-dried to obtain a hydrophilic polytetrafluoroethylene flat porous membrane. After 5 hours, the flux recovery rate was higher than 39.9% after water washing.

Embodiment 2

[0019] 1) First, fully wash the PTFE flat porous membrane with ethanol to remove impurities on the surface of the membrane, and then perform corona treatment after drying, with a treatment power of 2400W and a time of 50S;

[0020] 2) Place the PTFE membrane treated in step (1) in polyethyleneimine solution containing N-(2-perfluorooctylsulfonamidoethyl)-β,β'-iminodipropionic acid disodium amino acid Among them, N-(2-perfluorooctylsulfonamidoethyl)-β,β'-iminodipropionate disodium amino acid concentration is 1.2wt%, polyethyleneimine concentration is 0.5wt%, impregnation After reacting for 180 minutes, the membrane was taken out, cleaned with a large amount of deionized water, and vacuum-dried to obtain a hydrophilic polytetrafluoroethylene flat porous membrane. , after 5 hours, the flux recovery rate was higher than 46.8% after washing with water.

Embodiment 3

[0022] 1) First, fully wash the PTFE flat porous membrane with ethanol to remove impurities on the surface of the membrane, and then perform corona treatment after drying, with a treatment power of 2000W and a time of 80S;

[0023] 2) Place the PTFE membrane treated in step (1) in polyethyleneimine solution containing N-(2-perfluorooctylsulfonamidoethyl)-β,β'-iminodipropionic acid disodium amino acid Among them, N-(2-perfluorooctylsulfonamidoethyl)-β,β'-iminodipropionate disodium amino acid concentration is 0.9wt%, polyethyleneimine concentration is 2.0wt%, impregnation After reacting for 120 minutes, the membrane was taken out, cleaned with a large amount of deionized water, and vacuum-dried to obtain a hydrophilic polytetrafluoroethylene porous membrane. After 5 hours, the flux recovery rate was higher than 73.6% after water washing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com