Flexible porous drilling machine and cutting method for support beam

A drilling machine and supporting beam technology, applied in the direction of boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc., can solve the problems of low efficiency, cumbersome work, high labor intensity, and avoid drilling Hole work, improve work efficiency, reduce the effect of drilling times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

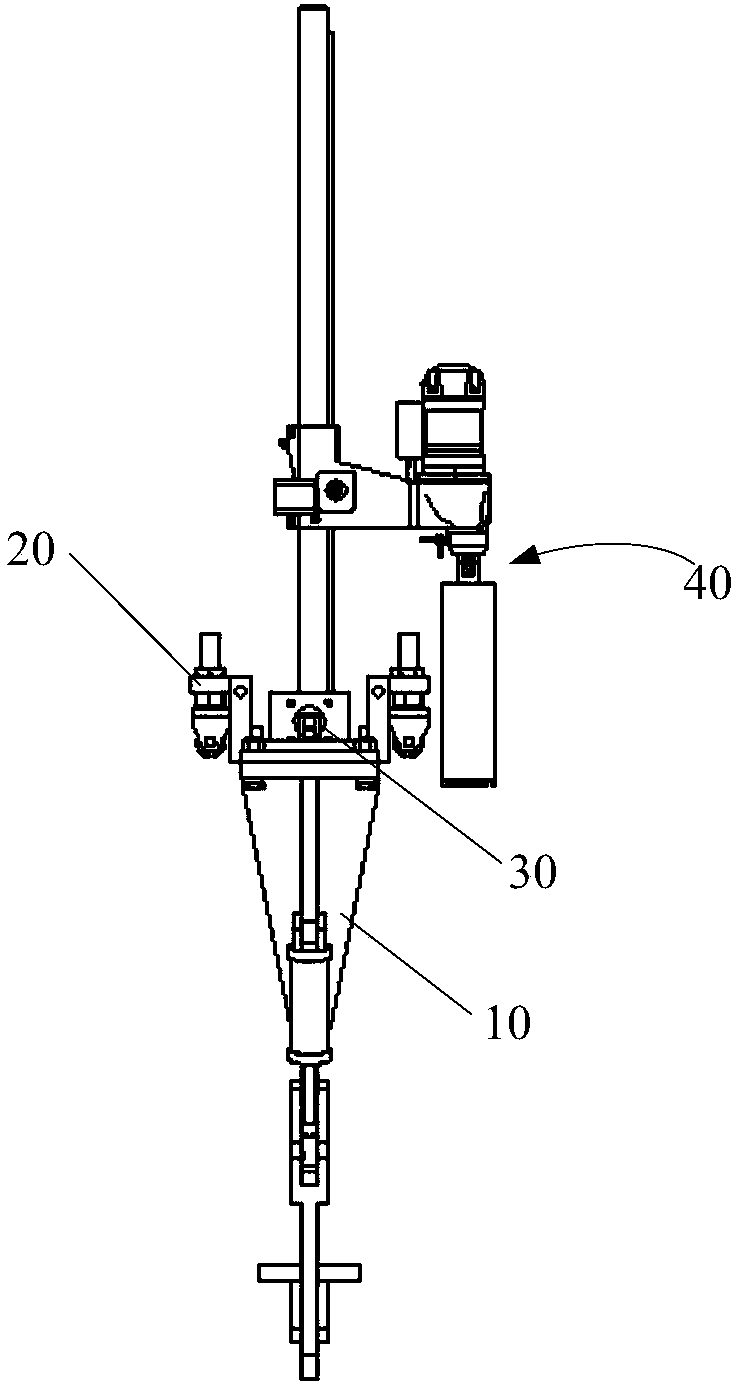

[0043] Such as Figure 1-3 As shown, the present invention provides a flexible multi-hole drilling machine, which includes a locking device 10 , a traveling device 20 , a translation device 30 and a drilling device 40 .

[0044]Wherein the locking device 10 is used to lock the drilling machine and the object to be drilled. In this embodiment, the object to be drilled is a support beam 50, especially a reinforced concrete support beam, and of course it can also be the support of other structures. Beam 50 or other similar structure to be drilled. When drilling, the drilling machine and the width direction of the support beam 50 are locked by the locking device 10 . Such as Figure 4 As shown, the locking device 10 includes a bottom plate 110, an oil cylinder mounting seat 120 installed on both sides below the bottom plate 110, a locking hook 130 movably connected with the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com