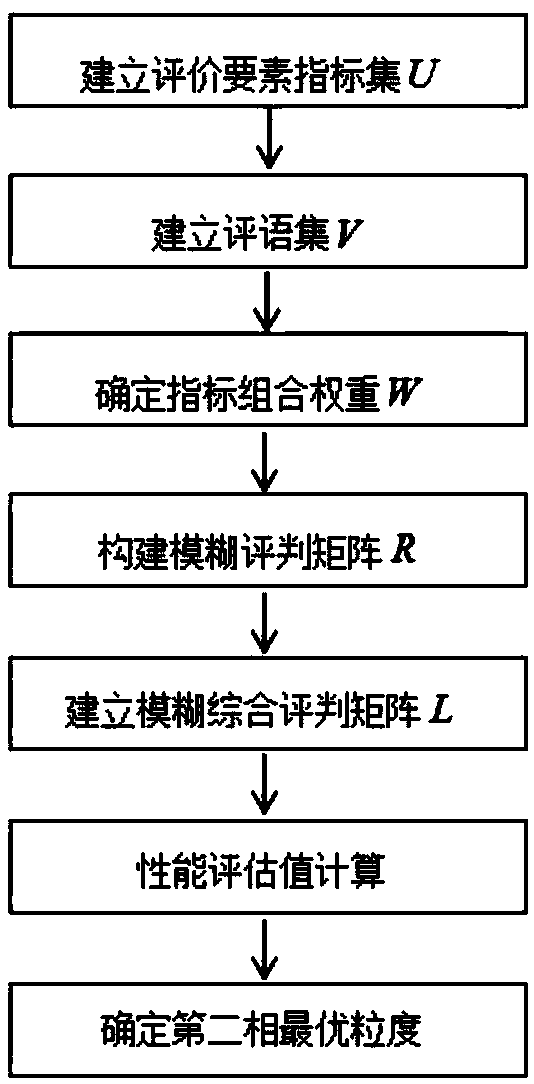

Method for determining optimal particle size of second phase of AgSnO2 contact material based on fuzzy comprehensive evaluation

A technology of fuzzy comprehensive evaluation and contact material, applied in the direction of instruments, data processing applications, prediction, etc., can solve the problems of no quantification, evaluation and determination, no objective specific data examples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

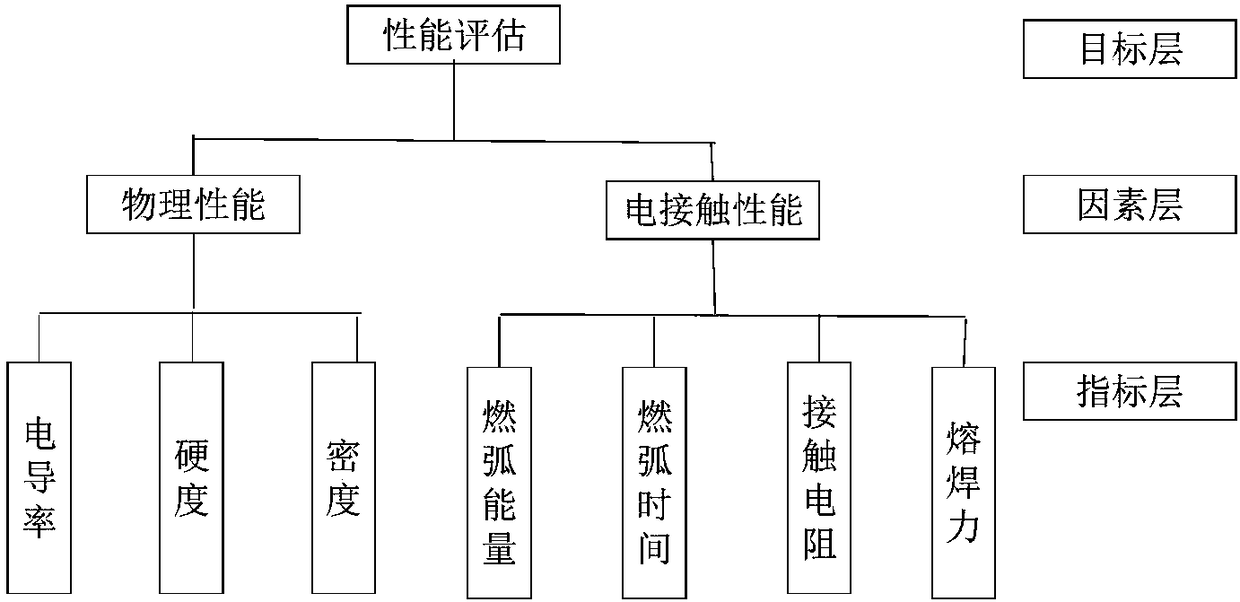

[0134] In this paper, the subjective weight is calculated using the improved analytic hierarchy process. exist figure 1 On the basis of the hierarchical structure of the evaluation elements shown, experts are invited to compare the importance of the four indicators of arcing energy, arcing time, contact resistance and welding force, and establish a comparison matrix A.

[0135]

[0136] Calculate the importance ranking index r of the four evaluation elements i , the calculation results are shown in Table 2:

[0137] Table 2 Importance ranking index table of each evaluation element

[0138]

[0139] Combined with the data in Table 2, the judgment matrix B is calculated

[0140]

[0141] Based on the judgment matrix B, the optimal transfer matrix C is calculated

[0142]

[0143] Then further calculation to get the quasi-optimal consistent matrix D

[0144]

[0145] Calculate the quasi-optimal consistency matrix to obtain the standardized eigenvector Z1=[0.46 0...

Embodiment 2

[0177] The difference is that the oxidant CuO is added, and the rest are the same.

[0178] Subjective weights are not affected by the original data, so in AgSnO 2 The subjective weight vector of each evaluation element in the evaluation process of the / CuO contact material performance remains unchanged: Z=[0.16 0.07 0.03 0.34 0.1 0.2 0.1]

[0179] AgSnO under the condition of different second phase particle size 2 Table 4 shows the test data of each indicator of the / CuO contact material.

[0180] Table 4 AgSnO 2 Raw data of each evaluation element of CuO contact material

[0181]

[0182] to AgSnO 2 The measured actual values of each evaluation element of the / CuO contact material were normalized to obtain a standardized matrix Y.

[0183]

[0184] The calculated entropy value of each evaluation element is:

[0185] H=[0.88 0.88 0.88 0.84 0.89 0.84 0.82]

[0186] The entropy weight (objective weight vector) of each evaluation element is calculated as:

[0187...

Embodiment 3

[0207] The difference is that the additive Bi 2 o 3 , and the rest are the same.

[0208] Subjective weights are not affected by the original data, so in AgSnO 2 / Bi 2 o 3 The subjective weight vector of each evaluation element of contact material performance is: Z=[0.16 0.07 0.03 0.34 0.1 0.2 0.1]

[0209] AgSnO under the condition of different second phase particle size 2 / Bi 2 o 3 The test data of various indicators of the contact material are shown in Table 5.

[0210] Table 5 AgSnO 2 / Bi 2 o 3 Raw data of each evaluation element of contact material

[0211]

[0212] to AgSnO 2 / Bi 2 o 3 The measured actual values of each evaluation element of the contact material are normalized to obtain a standardized matrix Y.

[0213]

[0214] The calculated entropy value of each evaluation element is:

[0215] H=[0.86 0.83 0.88 0.8 0.87 0.88 0.88]

[0216] The entropy weight (objective weight vector) of each evaluation element is calculated as:

[0217] E=[0.14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com