Placement type probe and visual quantitative evaluation method for damage detection of metal component

A metal component, damage detection technology, applied in the direction of measuring devices, material magnetic variables, instruments, etc., can solve rare problems, and achieve the effect of increasing the detection rate and improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

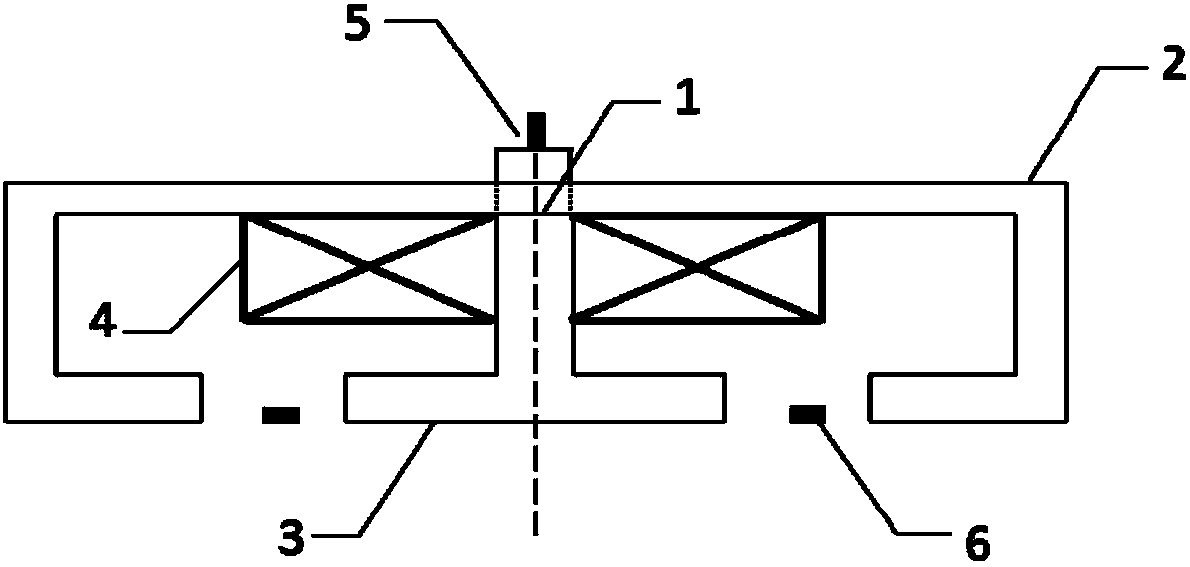

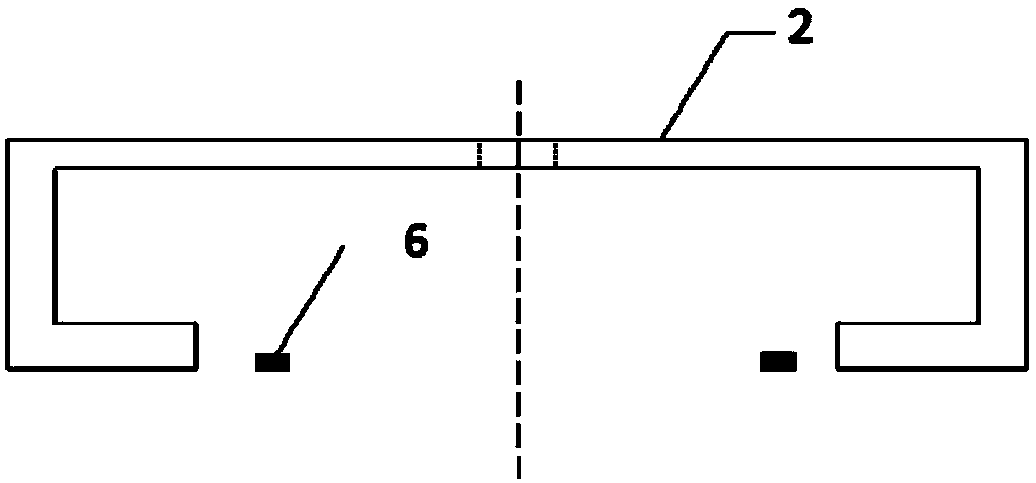

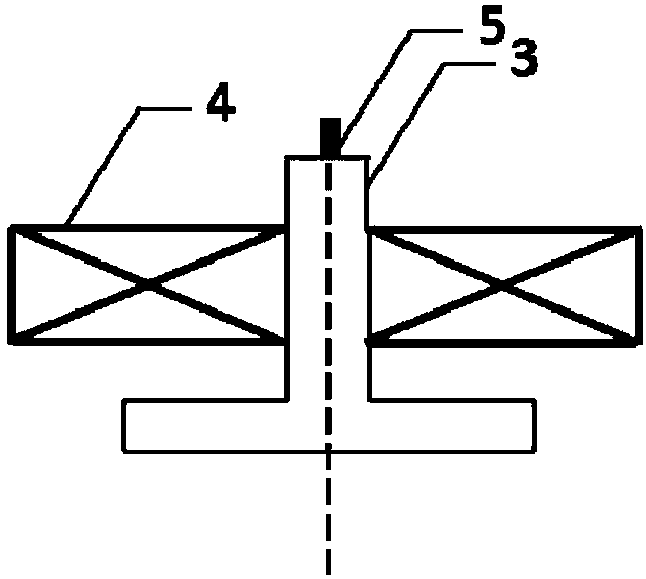

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, the placement probe for metal component damage detection of the present invention includes a magnetization gathering core group 1, a disc excitation coil 4 fixed on the magnetism gathering core group 1, a vertical magnetic field gradient sensor 5 and a group of annular distributed magnetic fields Gradient sensor array6. The magnetic gathering core group 1 is composed of a non-closed "mouth" shaped cylindrical core 2 at the bottom center of the axial section and a cylindrical magnetic core 3 with a "⊥" shaped axial section, and the two cylindrical magnetic cores are coaxial; the disc type The excitation coil 4 is coaxial with the magnetic core group 1; the vertical magnetic field gradient sensor 5 is located at the top of the "⊥"-shaped cylindrical magnetic core 3;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com