Preparation method of low air-entraining type solid polycarboxylic acid water reducing agent

A technology of polycarboxylic acid and water reducer, which is applied in the field of construction admixtures, can solve the problems of reducing concrete strength and durability, high air content, and unstable compound mixture, and achieve enhanced durability, high automation control precision, The effect of strong controllability of molecular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

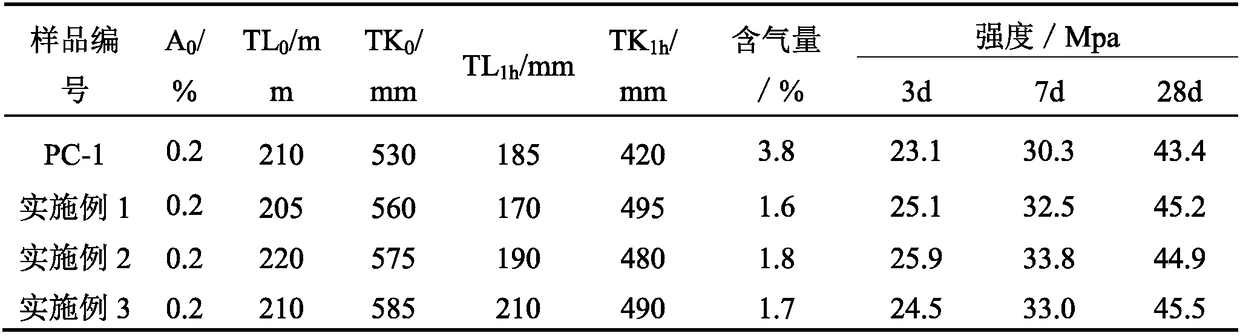

Embodiment 1

[0021] (1) Add 178g of diethyltoluenediamine, 294g of maleic anhydride, and 4.5g of 2,4-dimethyl-6-tert-butylphenol into the reaction kettle, under the protection of nitrogen, the microwave is heated to 70°C and added 2.0g solid phosphoric acid and 1.5g iron sulfate, heated to 120℃, kept for 2h, then added 400g of polyetheramine, kept keeping the reaction for 2h, during which time the water was removed by nitrogen and water, after the reaction, the temperature was reduced to room temperature. Unsaturated acid diacylation product;

[0022] (2) Add 200g of ester polyether monomer MPEGMAn to the reaction kettle, heat it to 60°C in microwave, add 2.0g of dibutyltin phthalate and stir for 10min, add 5g of maleic anhydride and 1.5 of liquid caustic at one time;

[0023] (3) Add dropwise a mixture of 10 g of unsaturated acid bisacylation product obtained in step (1) and 2.3 g of bis(2,4-dichlorobenzoyl) peroxide to the material obtained in step (2), while dropping Add a mixture of 4g of ...

Embodiment 2

[0026] (1) Add 178g of diethyltoluenediamine, 348g of fumaric acid, and 6g of 4-hydroxypiperidinol oxygen radicals into the reaction kettle, under the protection of nitrogen, microwave the temperature to 70°C, add 3.5g of solid phosphoric acid and 1g Ferric sulfate, heated to 110℃, heat preservation reaction for 1.5h, then add 500g polyetheramine, continue heat preservation reaction for 3h, during which the water is removed by nitrogen and water, after the reaction, the temperature is reduced to room temperature to obtain unsaturated acid double acylation product;

[0027] (2) Add 200g of ester polyether monomer MPEGMAA to the reactor, heat it to 60°C in microwave, add 2.8g of dibutyltin phthalate and stir for 10min, then add 5g of fumaric acid and 1.5g of liquid caustic at once;

[0028] (3) Add dropwise the mixture of 6g unsaturated acid diacylation product obtained in step (1) and 2.5g dioctanoyl peroxide to the material obtained in step (2), while adding 2g hydroxypropyl acryla...

Embodiment 3

[0031] (1) Add 178g of diethyltoluenediamine, 490g of maleic anhydride, and 4g of 4-hydroxypiperidinol oxygen radicals into the reaction kettle. Under the protection of nitrogen, the temperature is raised to 70°C in a microwave oven, and 4g of solid phosphoric acid and 1g Antimony oxide was heated to 110°C, and the temperature was kept for 3 hours, then 600g of polyetheramine was added, and the reaction was continued for 1.5 hours. During this time, the water was removed by nitrogen and water. After the reaction, the temperature was reduced to room temperature to obtain the unsaturated acid diacyl Chemical product

[0032] (2) Add 100g of ester polyether monomer MPEGMAA and 100g of ester polyether monomer MPEGMAn into the reactor, microwave heating to 60℃, add 1.5g dibutyltin phthalate and 1.0g tetraethyleneimine and stir After 10 minutes, 4g maleic anhydride and 1.2g liquid caustic soda were added at once;

[0033] (3) To the material obtained in step (2), add dropwise 10 g of un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com