Frosting liquid, preparation method and uses thereof, and anti-glare glass preparation method

A technology of anti-glare glass and frosting liquid, which is applied in the field of glass, can solve the problems of poor light transmittance, atomization rate, poor impact resistance, cumbersome preparation process, and high cost, and achieve the best anti-glare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention also relates to a preparation method of the above-mentioned frosting solution, which comprises mixing ammonium fluoride, sulfuric acid, calcium fluoride, ammonium sulfate, potassium sulfate and water.

[0054] The preparation method of the above-mentioned frosting liquid of the present invention is simple and suitable for industrial production.

[0055] The present invention also relates to the use of the above-mentioned frosting solution for preparing anti-glare glass.

[0056] The above application of the present invention can prepare glass with high light transmittance and good anti-glare effect.

[0057] The present invention also relates to a method for preparing antiglare glass, said method comprising the following steps: (1) putting the glass into the above-mentioned frosting liquid; (2) passing gas (for example, air or inert glass) into the frosting liquid gas) for the reaction.

[0058] The above method of the present invention does not ...

Embodiment 1

[0076] 1. Prepare frosting solution

[0077] The frosting liquid is mixed by the following raw materials in parts by weight:

[0078] 12 parts of ammonium fluoride, 10 parts of sulfuric acid (98%), 5 parts of calcium fluoride, 5 parts of ammonium sulfate, 18 parts of potassium sulfate, 135 parts of pure water.

[0079] Weigh the raw materials in the above parts by weight, add the sulfuric acid solution into the water according to the proportion and stir evenly, add ammonium fluoride, calcium fluoride, ammonium sulfate, and potassium sulfate, stir evenly, and then age to obtain the frosting solution.

[0080] 2. Preparation method of anti-glare glass

[0081] Refer to the following steps to prepare anti-glare glass: ①Clean the glass and control the temperature of the frosting solution at 24°C; Put the glass into the polishing solution (5% HF acid) and polish it for 5 minutes after sanding; ④ Clean and dry to obtain the anti-glare glass.

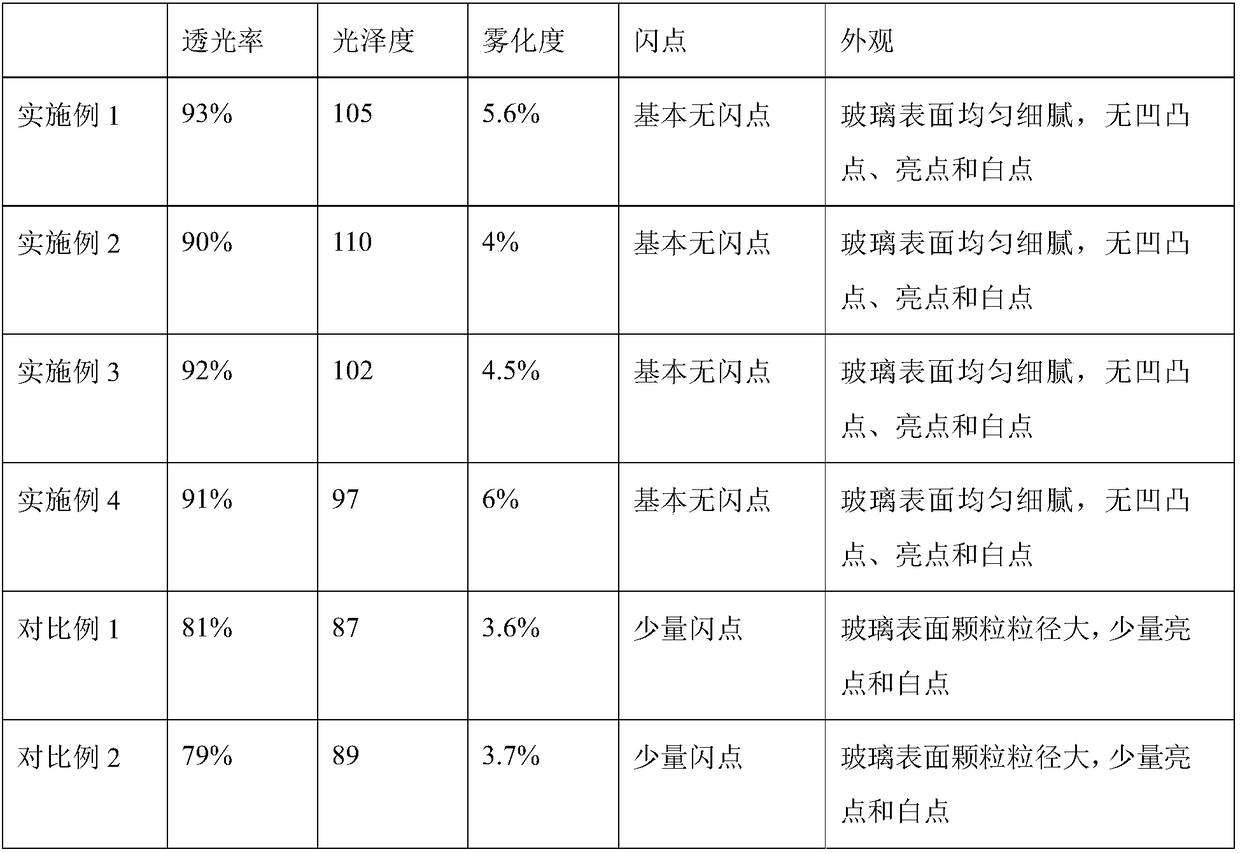

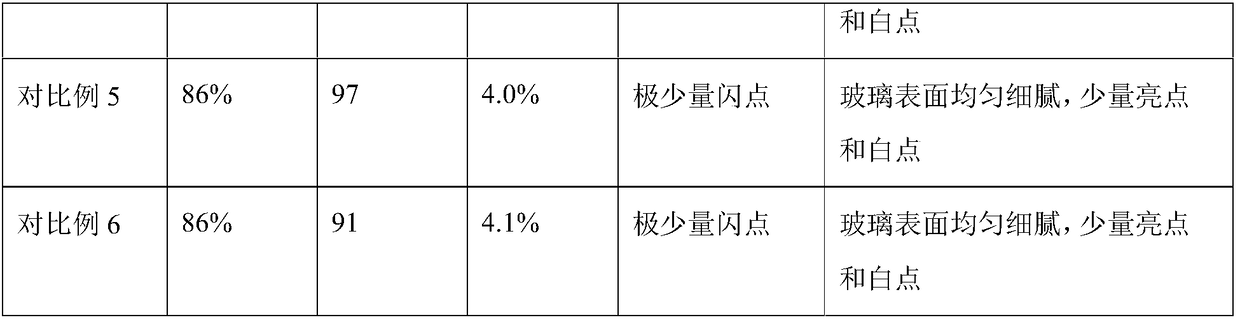

[0082] 3. Determination of the perfo...

Embodiment 2

[0085] The formula for the frosting solution is as follows:

[0086] The frosting liquid is prepared by mixing the following raw materials in parts by weight: 14 parts of ammonium fluoride, 7 parts of sulfuric acid (98%), 4 parts of calcium fluoride, 4 parts of ammonium sulfate, 15 parts of potassium sulfate and 130 parts of pure water.

[0087] Referring to the method described in Example 1, the frosting solution was prepared, the anti-glare glass was prepared, and the performance of the anti-glare glass was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com