Conveying belt type surface pressure film-covering and coating process and device

A conveyor belt and surface pressure technology, which is applied in the field of conveyor belt surface pressure film coating process and equipment, can solve the problems of coating waste, narrow film coating pressure line, and high coating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

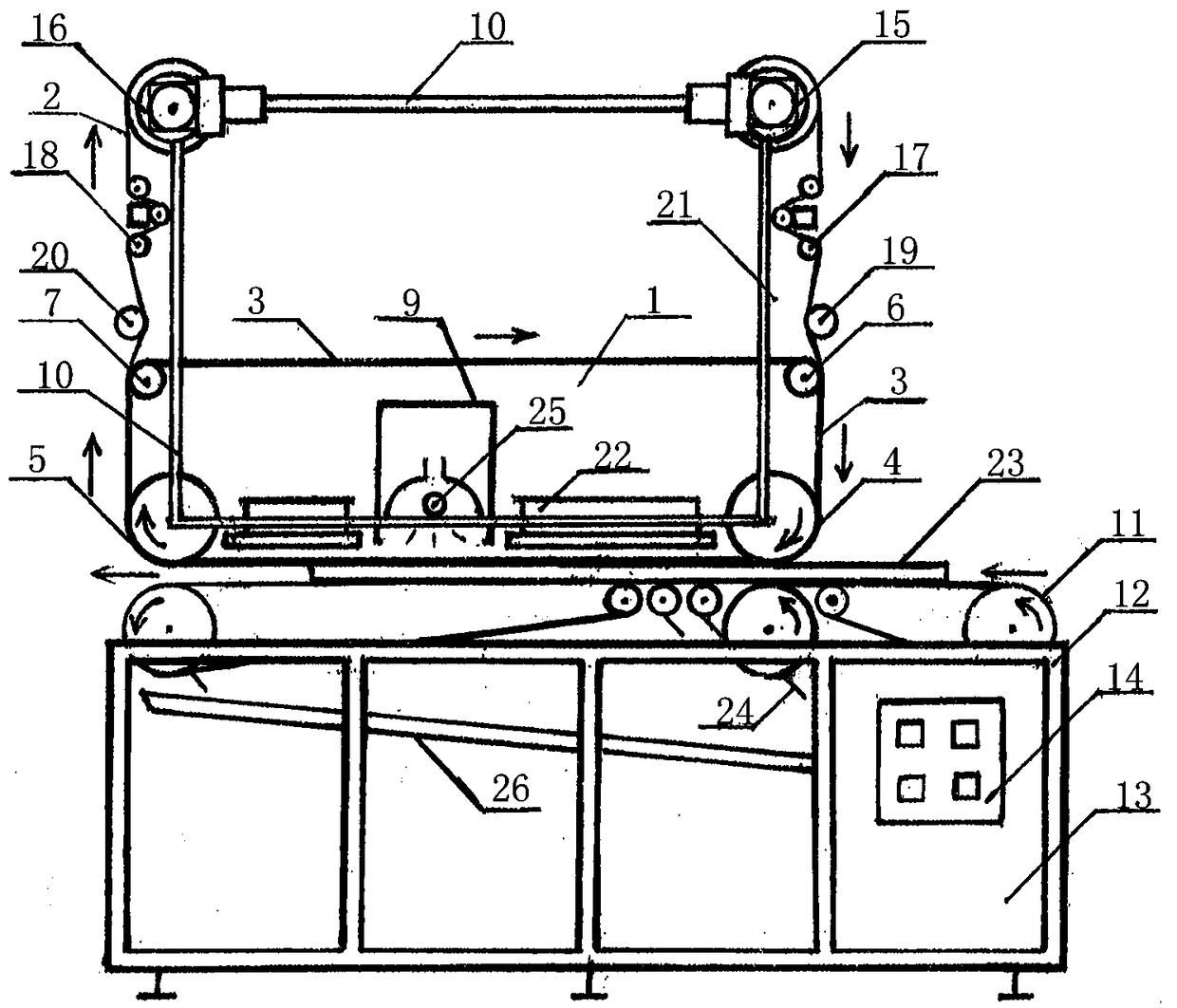

[0077] Embodiment one: with reference to attached figure 1

[0078]A conveyor belt type surface pressure film coating device is characterized in that it includes:

[0079] The frame 12, the film surrounding frame 21 of the conveyer belt type surface pressure film coating device 1 including the film peeling off the rear roller end, the coating object carrying device 11, the speed regulating motor, the power distribution system 13, and the operation box 14;

[0080] A conveyor belt type surface pressure film coating device consists of:

[0081] The conveyer-belt type surface pressure film coating device for removing the film at the end of the rear roller comprises: a conveyer belt 3, a front roller 4, a rear roller 5, a front tension roller 6, a rear tension roller 7, a paint curing device 9, an adjusting speed motor;

[0082] The conveyor belt type surface pressure film coating device for removing the film at the rear roller end is composed of: a front roller 4 and a rear ro...

Embodiment 2

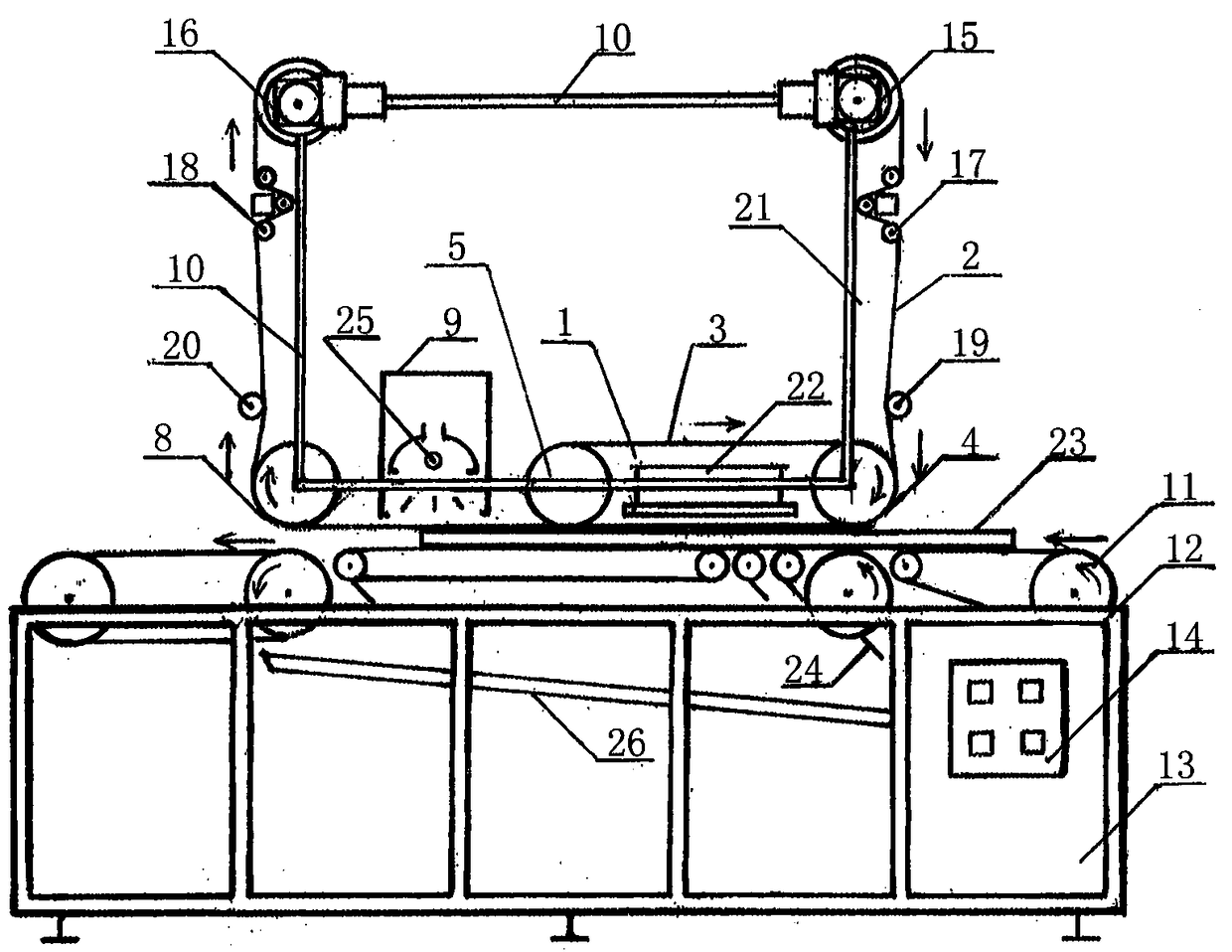

[0094] Embodiment two: refer to the appended figure 2 .

[0095] A conveyor belt type surface pressure film coating device is characterized in that it includes:

[0096] Frame 12, the film surrounding frame 21 of the conveyor belt type surface pressure film coating device 1 including the film peeling roller, the coating object carrying device 11, the speed regulating motor, the power distribution system 13, and the operation box 14;

[0097] A conveyor belt type surface pressure film coating device consists of:

[0098] The conveyer-belt type surface pressure film coating device for removing the film by the film-removing roller comprises: a conveyor belt 3, a front roller 4, a rear roller 5, a film-removing roller 8, a paint curing device 9, and a speed-regulating motor;

[0099] The conveyor belt type surface pressure coating device for peeling off the film is composed of: the front roller 4 and the rear roller 5 are arranged in the conveyor belt 3 loops, and the rear roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com