Garbage crusher capable of reducing crushing work pressure of cutter

A working pressure and pulverizer technology, which is applied to presses, manufacturing tools, grain processing, etc., can solve the problems of time-consuming and labor-intensive, no compression function, and garbage trucks cannot be loaded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

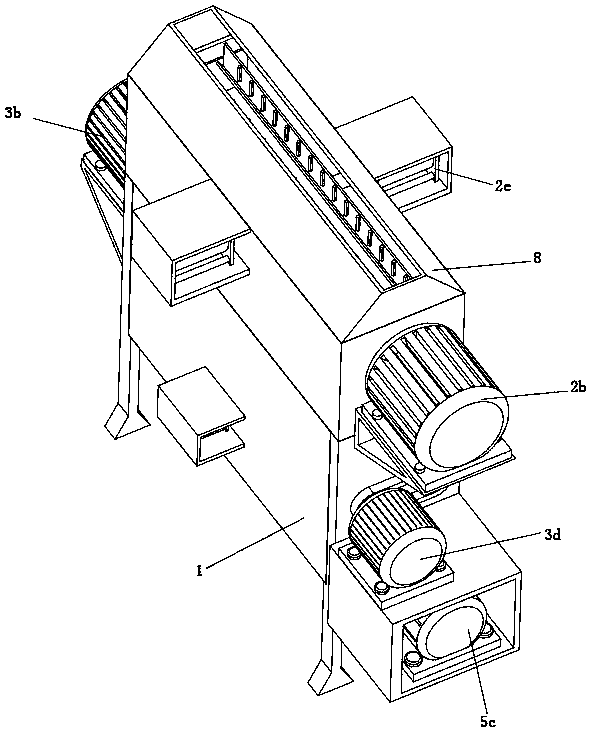

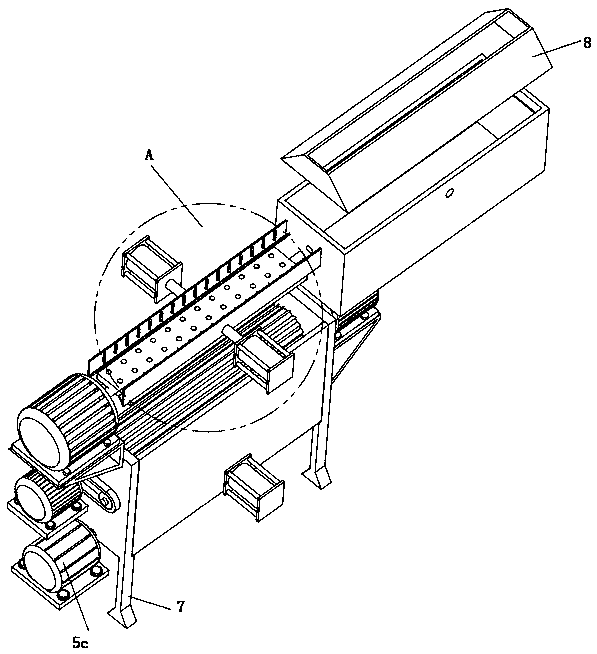

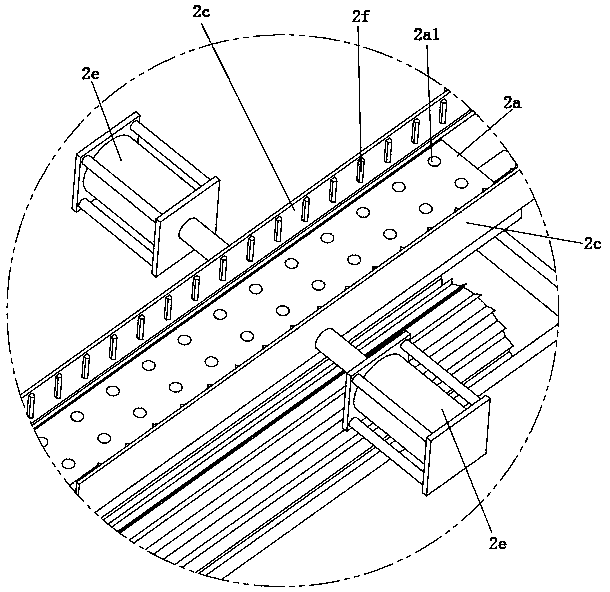

[0027] refer to Figure 1 to Figure 9 The shown garbage shredder which can reduce the working pressure of cutter crushing includes a crushing bin 1, a large crushing part 2 located in the crushing bin 1 and arranged in sequence from top to bottom, a three-axis crushing part 3, a compression part and a row The material part, the large crushing part 2 includes a transition plate 2a and two crushing plates 2c, the transition plate 2a is set at the middle position of the top inside the crushing bin 1, and the left outer side of the crushing bin 1 is provided with a step for driving the transition plate 2a to turn over Into the motor 2b, two crushing plates 2c are respectively arranged on both sides of the transition plate 2a that can move towards the direction of the transition plate 2a, the three-axis crushing part 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com