Hydrogenation catalyst and preparation method, and 1,2-pentanediol preparation method

A hydrogenation catalyst and catalyst technology, applied in the field of hydrogenation, can solve the problem of single derivatives, achieve high conversion rate of furfural, reduce catalyst activity, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

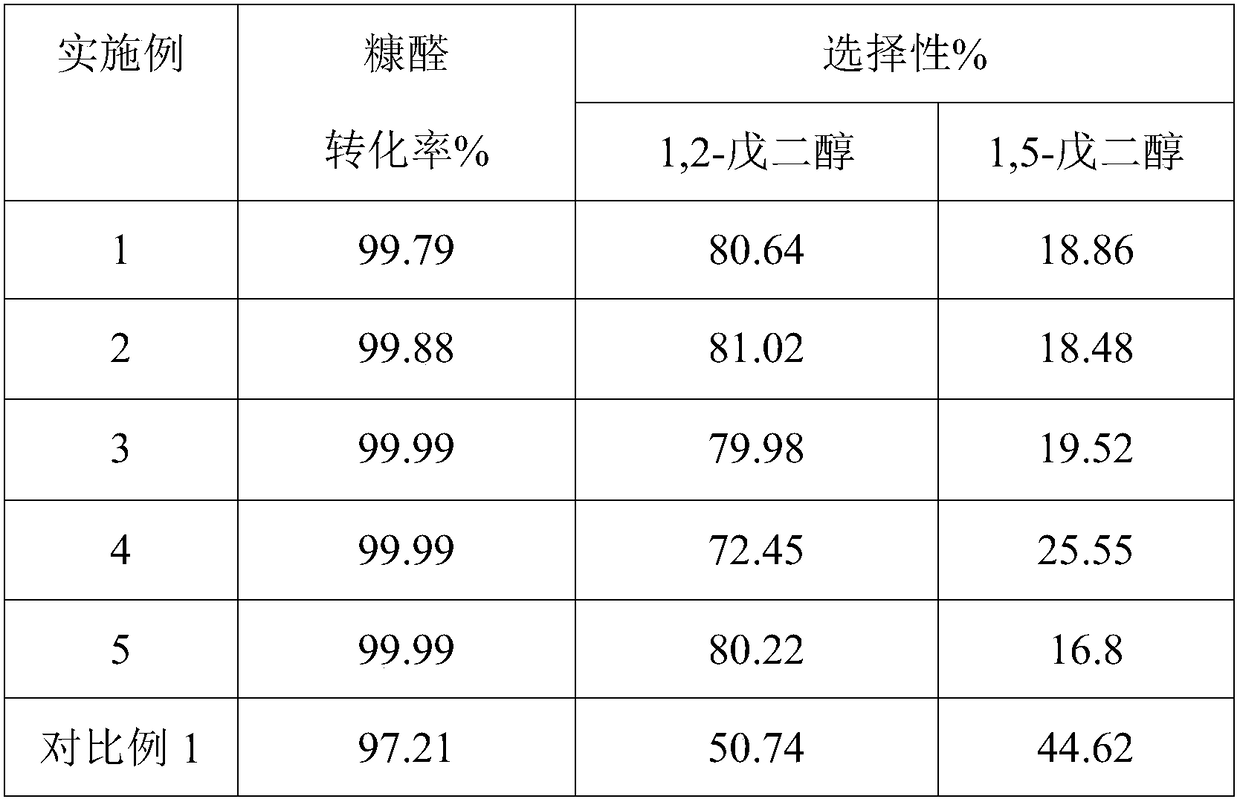

Examples

Embodiment 1

[0058] 198g of 25wt% neutral silica sol was formulated into a 0.2mol / L aqueous silica sol solution, placed in the reaction kettle and heated to 80°C.

[0059] 98.15gCu(NO 3 ) 2 ·3H 2 O, 51.3gCrO 3 , 21.9gCa(NO 3 ) 2 4H 2 O and 9.64g Li 2 CO 3 Dissolved in 1854g of water to prepare an aqueous solution of salt.

[0060] Sodium carbonate is formulated into a 15wt% aqueous solution of the precipitating agent.

[0061] Heat the two solutions to 80°C respectively, then add the two solutions into the reactor in parallel flow, control the temperature in the reactor to 80°C, the precipitation pH to 6.5, and the precipitation time to 2h, then age at 60°C for 3h to obtain a slurry . Then it was washed, filtered, dried at 100°C for 6h, and 65g was taken out and baked at 320°C for 8h. Afterwards, it is pressed into tablets to obtain a 5*5mm cylinder, which is the 1-1# catalyst. Another 65g was compressed into tablets and used as a carrier for later use.

[0062] 7.31g RuCl at ...

Embodiment 2

[0067] 195g of 25wt% neutral silica sol was formulated into a 0.3mol / L aqueous silica sol solution, placed in the reaction kettle and heated to 70°C.

[0068] 117.78gCu(NO 3 ) 2 ·3H 2 O, 42.8g CrO 3 and 32.8gCa(NO 3 ) 2 4H 2 O and 4.82gLi 2 CO 3 Dissolved in 1866g of water to prepare an aqueous solution of salt.

[0069] Sodium carbonate is formulated into a 15wt% aqueous solution of the precipitating agent.

[0070] Heat the two solutions to 70°C respectively, then add the two solutions into the reactor in parallel flow, control the temperature in the reactor to 70°C, the precipitation pH to 7.5, and the precipitation time to 1h, then age at 75°C for 2h to obtain a slurry . Then washed, filtered, dried at 120°C for 4h, and 65g was roasted at 280°C for 6h. Afterwards, tablet molding was performed to obtain a 5*5mm cylinder, and the remaining 65 g of the 2-1# catalyst was obtained for tablet molding as a carrier for later use.

[0071] 7.31g RuCl at room temperature...

Embodiment 3

[0076] 190 g of 25 wt % neutral silica sol was prepared into a 0.4 mol / L aqueous silica sol solution, placed in the reaction kettle, and heated to 60° C.

[0077] 137.41gCu(NO 3 ) 2 ·3H 2 O, 34.2g CrO 3 , 43.8gCa(NO 3 ) 2 4H 2 O and 1.61g Li 2 CO 3 Dissolved in 1887g of water to prepare an aqueous solution of salt.

[0078] Sodium carbonate is formulated into a 15wt% aqueous solution, that is, a precipitating agent aqueous solution.

[0079] Heat the two solutions to 60°C respectively, then add the two solutions into the reactor in parallel flow, control the temperature in the reactor to 60°C, the precipitation pH to 8.5, the precipitation time to 0.5h, and then age at 90°C for 1h to obtain slurry. Then it was washed, filtered, dried at 100°C for 6h, and 65g was taken out and baked at 320°C for 4h. Afterwards, it is pressed into a tablet to obtain a 5*5mm cylinder, which is the 3-1# catalyst. Another 65g was compressed into tablets and used as a carrier for later u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com