A method for improving the tensile strength and sensory quality of reconstituted tobacco leaves

A technology for reconstituting tobacco leaves and sensory quality, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of loss of natural plant aroma components, reduce the application effect of natural plants, etc., and achieve rich aroma style, good appearance quality effect, natural and soft luster Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

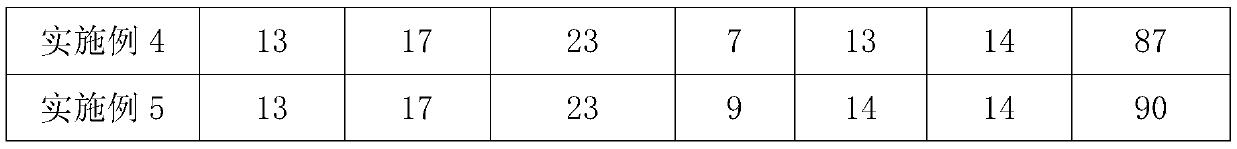

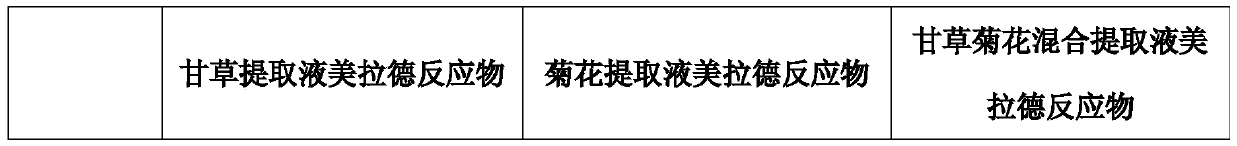

Examples

Embodiment 1

[0022] A method for improving the tensile strength and sensory quality of reconstituted tobacco leaves provided in Example 1 is characterized in that the specific steps include:

[0023] (1) Cut licorice into 8cm sections, mix it with chrysanthemum at a mass ratio of 10:2, then add 25% ethanol solution 6 times its total weight, and conduct ultrasonic extraction for 40min at 50°C and ultrasonic frequency 60kHz , to obtain plant residue and extract A through solid-liquid separation;

[0024] (2) Put the extract A prepared in step (1) at room temperature for 36 hours, take the supernatant and separate it with a butterfly separator, collect the filtrate and concentrate it under reduced pressure to a semi-fluid state to obtain an extract;

[0025] (3) The extract obtained by concentrating in the step (2) is dropped into the Maillard reaction tank body, add its weight 2% glycine and its weight 7% propylene glycol successively, keep heating temperature 95, stirring speed 100r / min Un...

Embodiment 2

[0030] A method for improving the tensile strength and sensory quality of reconstituted tobacco leaves provided in Example 2 is characterized in that the specific steps include:

[0031] (1) Cut the licorice into 12cm sections, mix it with the chrysanthemum at a mass ratio of 10:3, then add 30% ethanol solution 4 times its total weight, and extract it by ultrasonic for 45min at 55°C and ultrasonic frequency 80kHz , to obtain plant residue and extract A through solid-liquid separation;

[0032] (2) The extract A prepared in step (1) was left to stand at room temperature for 24 hours, the supernatant was filtered by a butterfly separator, and concentrated under reduced pressure to a semi-fluid state to obtain an extract;

[0033] (3) The extract obtained by concentrating in step (2) is dropped into the Maillard reaction tank body, add its weight 3% glycine and its weight 7.5% propylene glycol successively, keep heating temperature 100 ℃, stirring speed 90r / Under the condition ...

Embodiment 3

[0038] A method for improving the tensile strength and sensory quality of reconstituted tobacco leaves provided in Example 3 is characterized in that the specific steps include:

[0039] (1) Cut the licorice into 12cm sections, mix it with the chrysanthemum at a mass ratio of 10:1, then add 40% ethanol solution 3.5 times its total weight, and conduct ultrasonic extraction for 90min at 50°C and ultrasonic frequency 50kHz , to obtain plant residue and extract A through solid-liquid separation;

[0040] (2) The extract A prepared in step (1) was left to stand at room temperature for 28 hours, and the supernatant was filtered by a butterfly separator, then concentrated under reduced pressure to a semi-fluid state, to obtain an extract;

[0041] (3) The medicinal extract obtained by concentrating in step (2) is dropped into the Maillard reaction tank body, add its weight 4% glycine and its weight 10% propylene glycol successively, keep heating temperature 95 ℃, stirring rate 95r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com