Universal chassis of paddy field working device driven with hydrostatic drive

A technology of hydrostatic drive and working device, applied in the field of agricultural machinery, can solve the problems of inability to realize infinitely variable speed change, complex and bulky transmission system, not meeting the requirements of light weight, etc., and achieves improved passability, good fuel economy, and flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

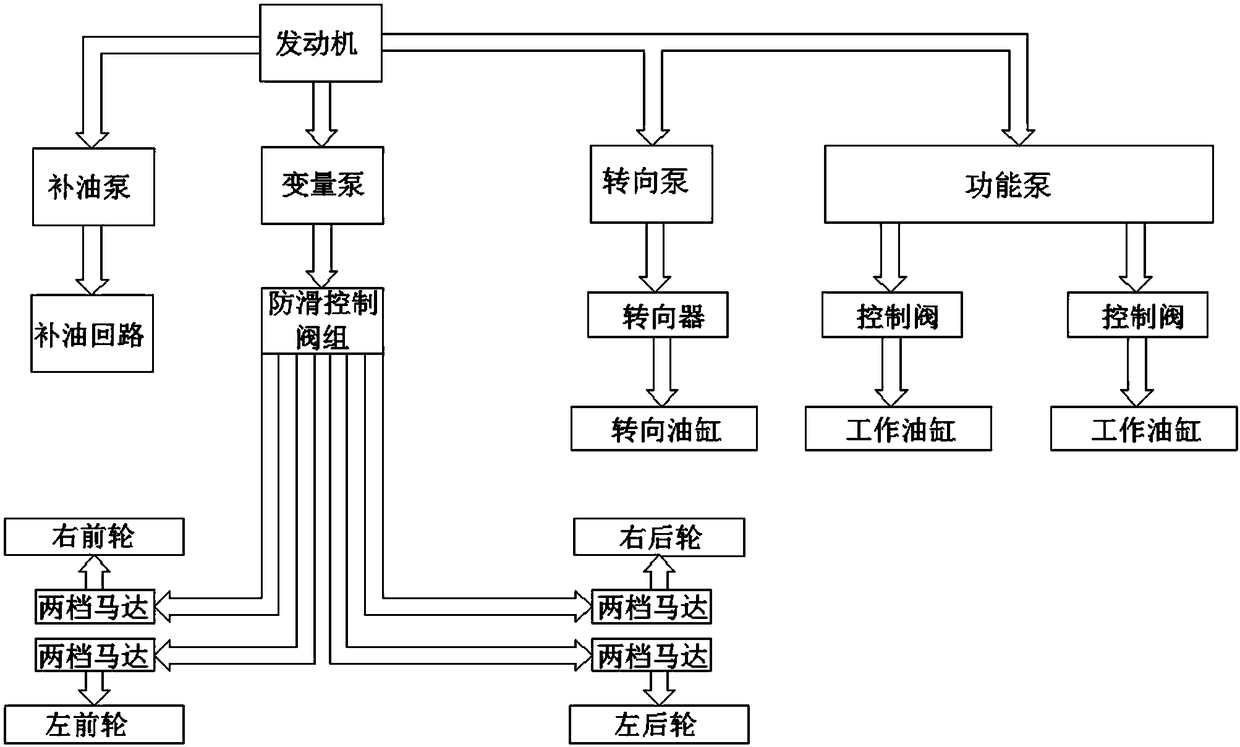

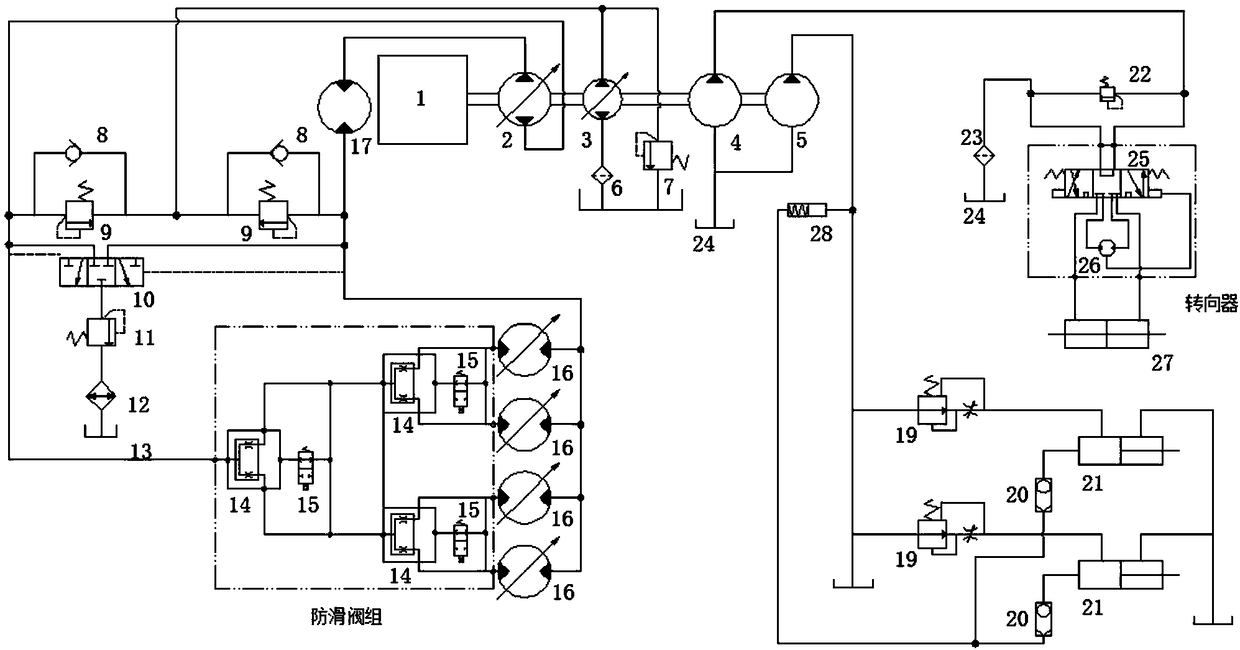

[0025] figure 1 Shown is the power transmission roadmap of the present invention, which mainly consists of three parts: 1) the traveling mechanism driven by the swash plate type bidirectional variable-variable plunger pump; 2) the steering mechanism powered by the gear pump; 3) the gear pump powered Source load-sensitive multi-actuator working mechanism.

[0026] The engine 1 is the power source of the whole system, which transmits the power to the two-way variable plunger pump and two gear pumps respectively through the connecting device. The valve group is connected with four two-stage variable travel motors. The two-way variable plunger pump itself has the dual functions of adjusting flow and changing flow direction, and can continuously adjust the speed and direction of the output shaft. The two-stage variable motor changes its displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com