Bus duct right-angle conversion structure

A technology of conversion structure and busway, which is applied in the direction of fully enclosed busbar devices, etc., can solve problems such as the difficulty of right-angled connection of busbars and the decline in connection reliability, and achieve the effects of simple structure, reduced difficulty, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

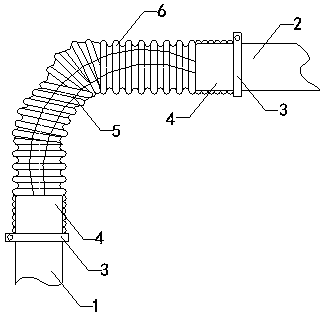

[0016] Combine below figure 1 and figure 2 And further illustrate the technical solution of the present invention through specific examples.

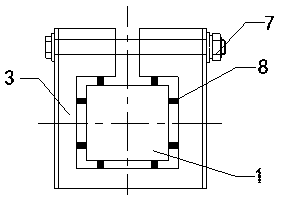

[0017] A busway right-angle conversion structure, comprising: a first busway housing 1, a second busway housing 2, a busway housing clamp 3, a busbar insertion guide 4 and a flexible conductive connector 5, the busway The middle of the housing clamp 3 is provided with a through hole for placing the bus duct, and an insulating shock absorbing block 8 is provided around the through hole, and a through slot communicating with the through hole is opened above the bus duct housing clamp 3. Bolts 7 are used to fasten the bus duct shell, and one side of the bus duct shell clamp 3 is connected with a busbar insertion guide groove 4, and a busbar insertion guide groove 4 is opened for insertion of the bus duct end. The two ends of the flexible conductive connector 5 are respectively connected with the busbar insertion guide groove 4 and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com