Reliability test device for cutting fluid cooling system of machining center

A test device and cooling system technology, applied in the direction of measuring devices, testing of machine/structural components, instruments, etc., to optimize system parameters and ensure accuracy and authenticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

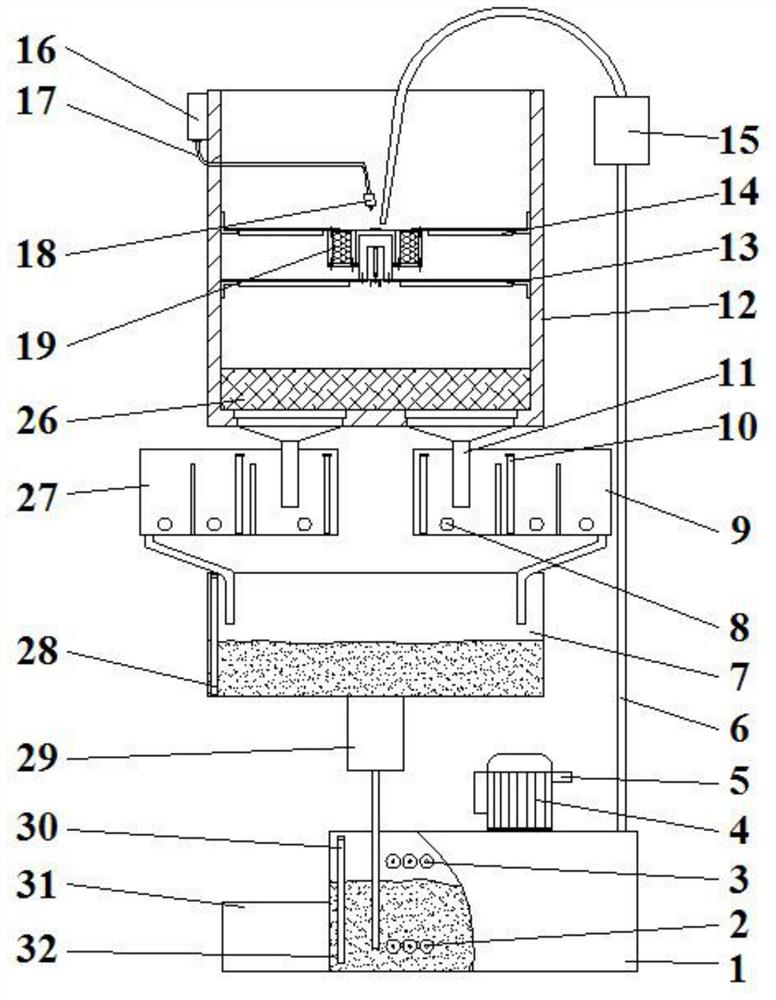

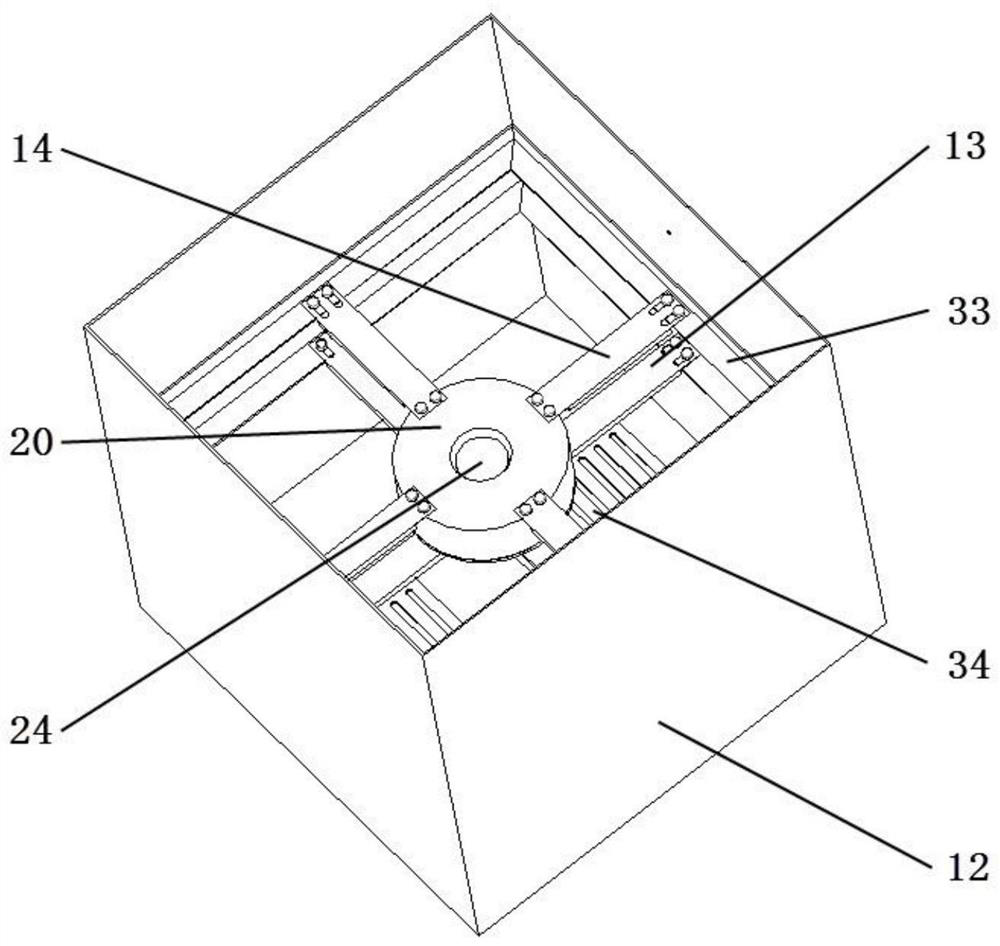

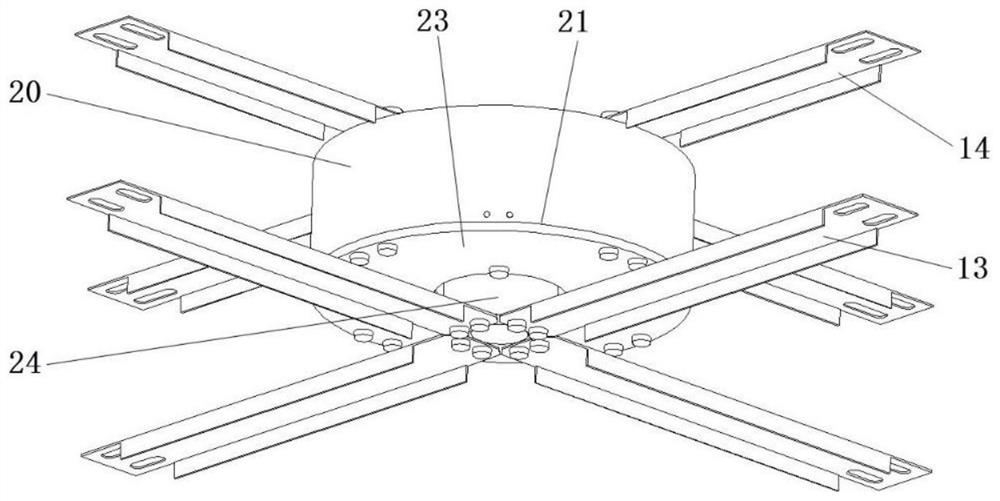

[0036] The machining center cutting fluid cooling system reliability test device includes a working condition simulation mechanism, a filtering mechanism, a cutting fluid delivery mechanism, a state monitoring and alarm mechanism and an automatic control mechanism.

[0037] 1. Working condition simulation mechanism

[0038] In the actual processing process, metal chips often contain a large amount of metal powder with a small particle size. Due to the small particle size of the metal powder, the primary filter device of the machining center cannot completely filter it out. Therefore, the metal powder enters the secondary filter system of the machining center after passing through the primary filter device with the flow of the cutting fluid, and is filtered by the secondary filter system. The metal powder is blocked by the filter screen of the filter device in the water tank of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com