A method of developing intelligent grading controller for grinding balls

A technology of controllers and grinding balls, applied in grain processing, etc., can solve problems such as slow progress, high cost, and environmental pollution, and achieve the effects of saving energy and reducing production costs, reducing production costs, and saving energy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

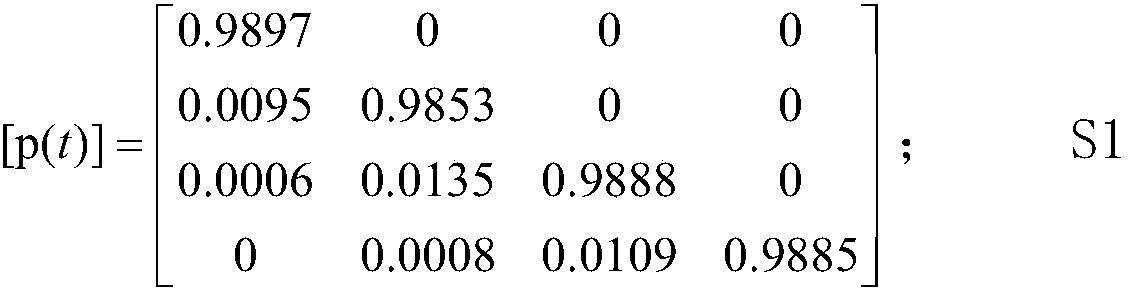

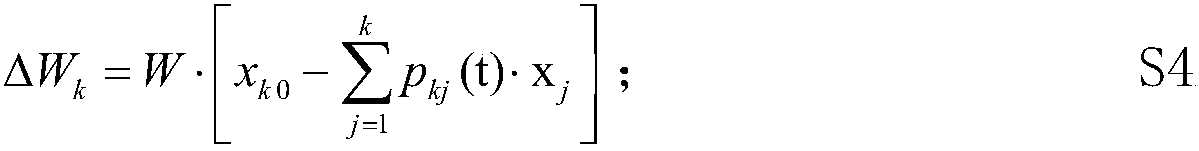

Image

Examples

Embodiment

[0074] A method for developing an intelligent grading controller for grinding balls, comprising the steps of:

[0075] (1) Reasonably select the type of ball mill according to the material characteristics of the abrasive, the working environment and work requirements of the ball mill, and select the specification of the ball mill according to the production capacity requirements of the ball mill user; when the abrasive is ferrous or non-ferrous metal ore, the ball mill selection Metal grinding machine; according to the material characteristics of the abrasive and the working environment of the ball mill, it is specifically: when the abrasive is non-metallic soft ore or non-metallic hard ore, the ball mill selects the grinding machine; according to the work of the ball mill Requirements, when the ball mill is under the condition of dry grinding or wet grinding, the coal mill should be selected; the specifications of the ball mill should be selected according to the production ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com