Single plunger pump with active flow distribution

A single-column, plug pump technology, applied to the components, pumps, pump elements, etc. of the pumping device for elastic fluids, can solve the problem of high input cost and maintenance cost, lag in closing or opening of one-way valve, influence Oil absorption and oil discharge strokes, etc., to simplify the hardware composition and software composition, improve reliability, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

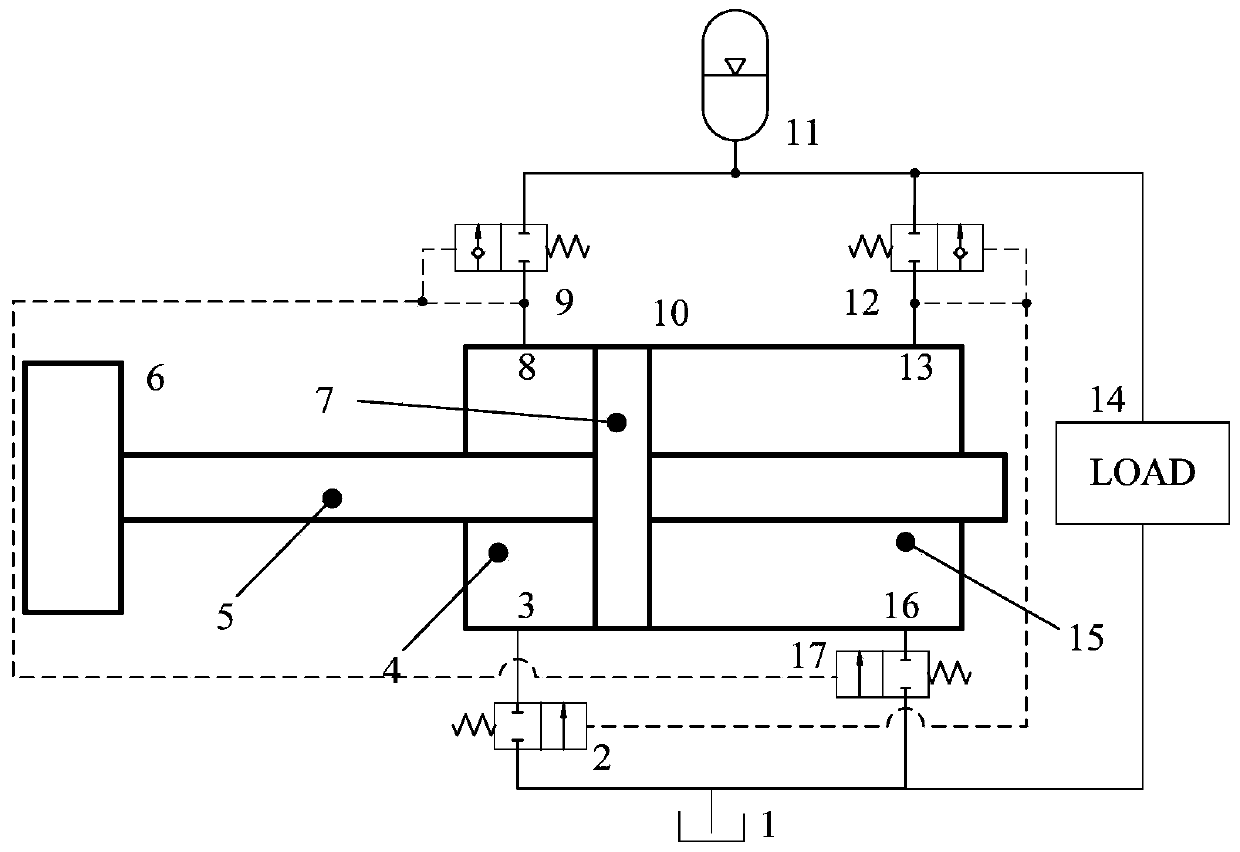

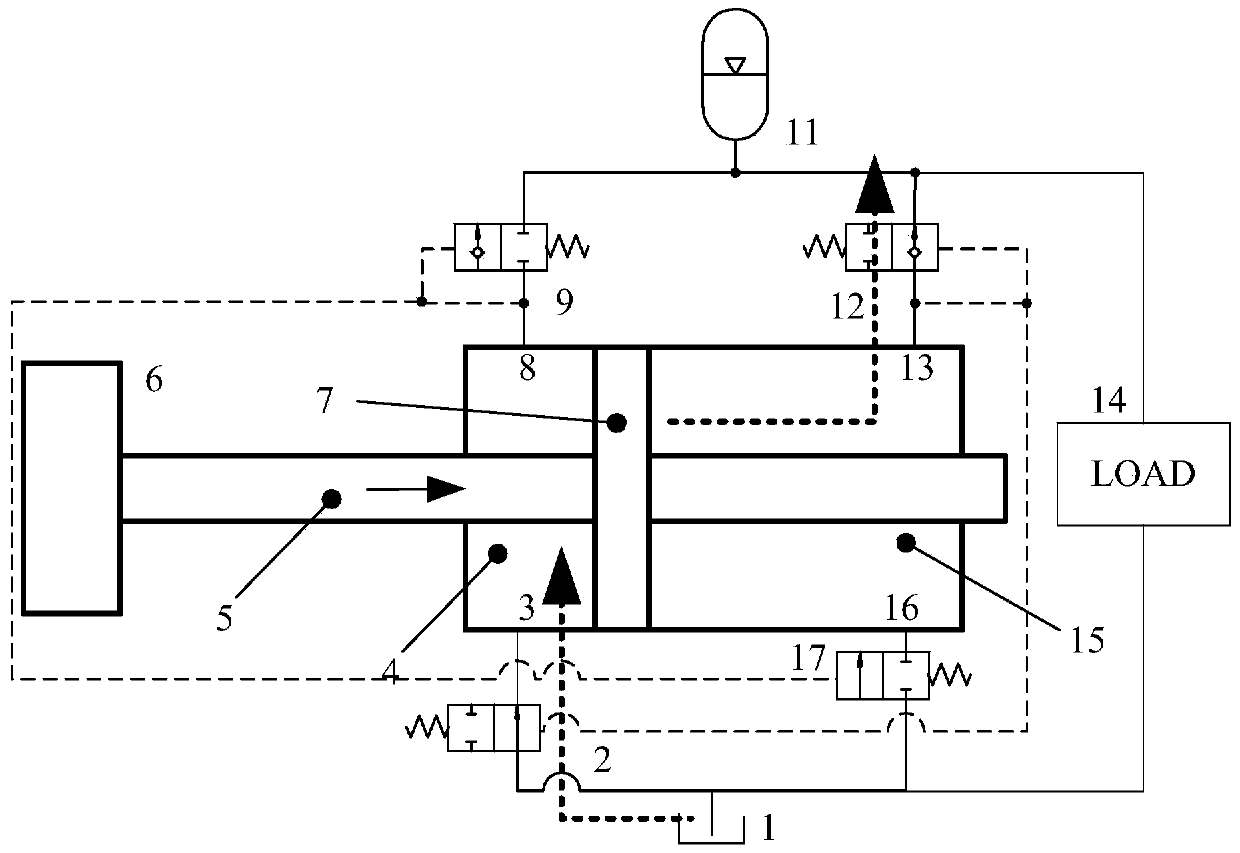

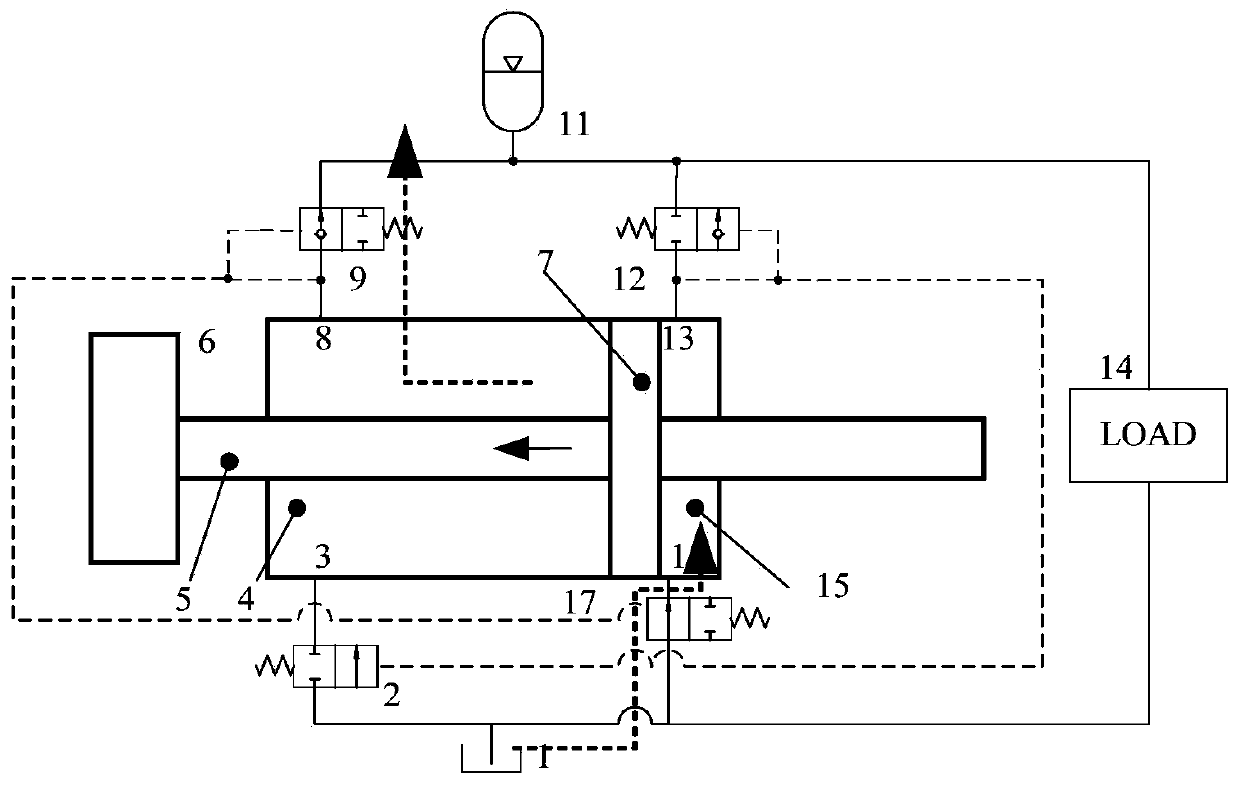

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0019] A single plunger pump with active flow distribution, refer to figure 1 , including a cylinder, a piston rod 5 and a piston 7. The cylinder is divided into a first pump chamber 4 and a second pump chamber 15 with equal effective areas by the piston 7. The first pump chamber 4 is provided with a first oil suction port 3 and a first pump chamber. The oil discharge port 8 and the second pump chamber 15 are provided with a second oil suction port 16 and a second oil discharge port 13; the first oil discharge port 8 and the second oil discharge port 13 are respectively connected with the first oil discharge valve 9 and the second oil discharge port The inlets of the two oil discharge valves 12 communicate; the first oil suction port 3 and the second oil suction port 16 communicate with the outlets of the first oil suction valve 2 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com