Synchronous plastering machine for double-faced wall

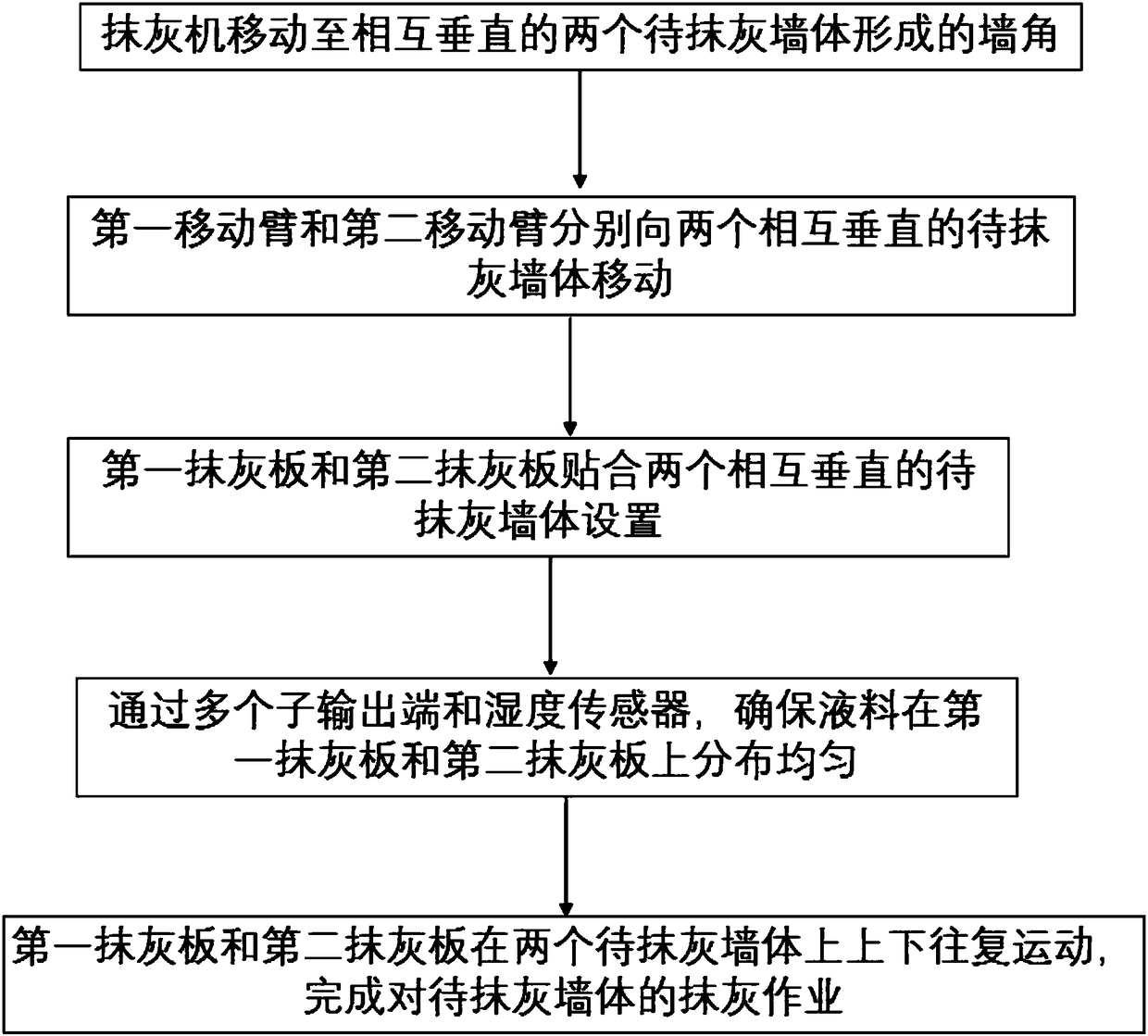

A plastering machine, double-sided technology, applied in construction, building structure and other directions, can solve the problems of complicated and complicated operation, and achieve the effect of easy operation, simple structure, and ensure the quality of plastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Other objects and advantages of the present invention will become clear by explaining the following preferred embodiments of the present application.

[0028] Various exemplary embodiments of the present invention will now be described in detail. The detailed description should not be considered as a limitation of the present invention, but rather as a more detailed description of certain aspects, features and embodiments of the present invention.

[0029] It should be understood that the terminology described in the present invention is only used to describe specific embodiments, and is not used to limit the present invention. In addition, regarding the numerical ranges in the present invention, it should be understood that each intermediate value between the upper limit and the lower limit of the range is also specifically disclosed. Each smaller range between any stated value or intervening value in a stated range and any other stated value or intervening value in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com