High-performance paint for polypropylene cat food packaging bag

A packaging bag, high-performance technology, applied in the field of coatings, can solve the problems of limited development, incomplete holographic effect, low production efficiency, etc., and achieve the effect of good adhesion fastness and outstanding laser effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

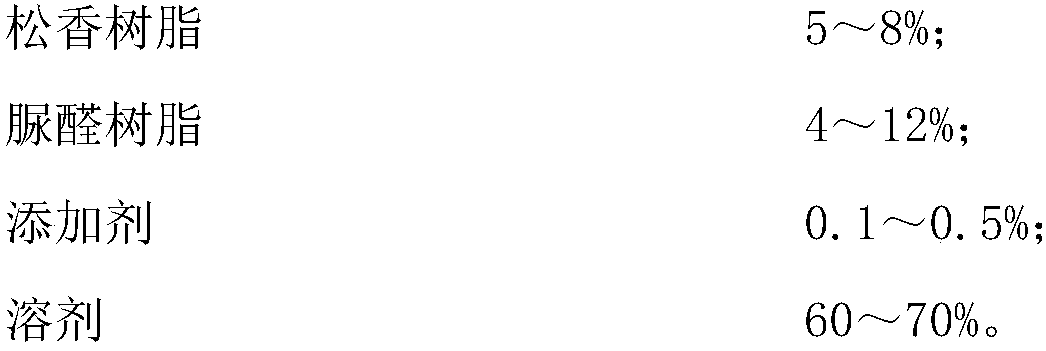

[0031] The high-performance coating composition that is used for polypropylene cat food packaging bag of the present embodiment adopts the raw material of component and content shown in Table 1 to prepare; Concrete preparation comprises following process steps:

[0032] (1) 40 kilograms of ethyl acetate and 20 kilograms of n-butyl acetate are dropped into the reactor, and the temperature is raised to 55° C.;

[0033] (2) 30 kilograms of high-viscosity polyvinyl acetate resin, 2.5 kilograms of gum rosin resin, 2.5 kilograms of wood rosin resin, and 4.9 kilograms of polyvinyl alcohol modified urea-formaldehyde resin are put into the reaction kettle, stirred at high speed for 4.0 hours, until fully dissolved;

[0034] (3) Add 0.1 kg of curing agent into the reaction kettle and stir until it is evenly dispersed.

[0035] Apply the coating directly to the coating machine, the leveling is average, the coating surface flatness is average, the molding temperature is 80-90°C, the moldi...

Embodiment 2

[0037] The high-performance coating composition that is used for polypropylene cat food packaging bag of the present embodiment adopts the raw material of component and content shown in Table 1 to prepare; Concrete preparation comprises following process steps:

[0038] (1) 20 kilograms of methyl isobutyl ketone, 40 kilograms of ethylene glycol monobutyl ether, and 10 kilograms of n-butanol are put into the reactor, and the temperature is raised to 55° C.;

[0039] (2) 6.0 kilograms of high-viscosity polyvinyl acetate resin, 4.0 kilograms of low-viscosity polyvinyl acetate resin, 2.0 kilograms of gum rosin resin, 4.0 kilograms of wood rosin resin, 2.0 kilograms of tall oil rosin resin, 9.0 kilograms of phenol modified urea-formaldehyde resin 1. Put 2.5 kg of polyvinyl alcohol modified urea-formaldehyde resin into the reactor, and stir at high speed for 2.5 hours until fully dissolved;

[0040] (3) Add 0.2 kg of dispersant and 0.3 kg of curing agent into the reaction kettle in ...

Embodiment 3

[0043] The high-performance coating composition that is used for polypropylene cat food packaging bag of the present embodiment adopts the raw material of component and content shown in Table 1 to prepare; Concrete preparation comprises following process steps:

[0044] (1) 10 kilograms of methyl isobutyl ketone, 20 kilograms of ethyl acetate, 25 kilograms of ethylene glycol monobutyl ether, and 10 kilograms of n-butyl acetate are dropped into the reactor, and the temperature is raised to 60° C.;

[0045] (2) 8.2 kilograms of high-viscosity polyvinyl acetate resins, 8.2 kilograms of low-viscosity polyvinyl acetate resins, 3.2 kilograms of gum rosin resins, 1.6 kilograms of wood rosin resins, 1.6 kilograms of tall oil rosin resins, and 8.0 kilograms of phenol-modified urea-formaldehyde resins 1. Put 4.0 kg of polyvinyl alcohol modified urea-formaldehyde resin into the reactor, and stir at high speed for 3.0 hours until fully dissolved;

[0046] (3) Add 0.1 kg of wetting agent a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com