Multifunctional Coatings for Polyethylene Candy Wrap Films

A packaging film and polyethylene technology, applied in the field of coatings, can solve the problems of incomplete holographic effects, limited development, low production efficiency, etc., and achieve outstanding coating anti-counterfeiting effects, good coating adhesion fastness, and wide molding adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

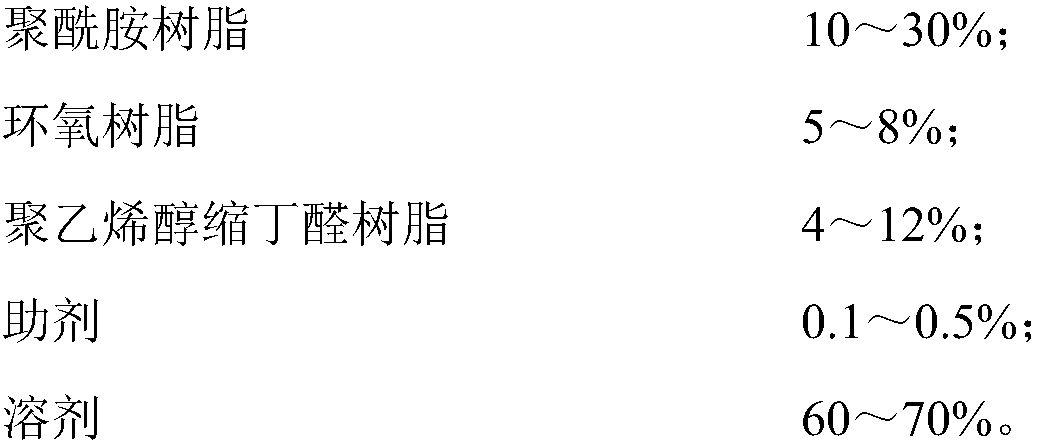

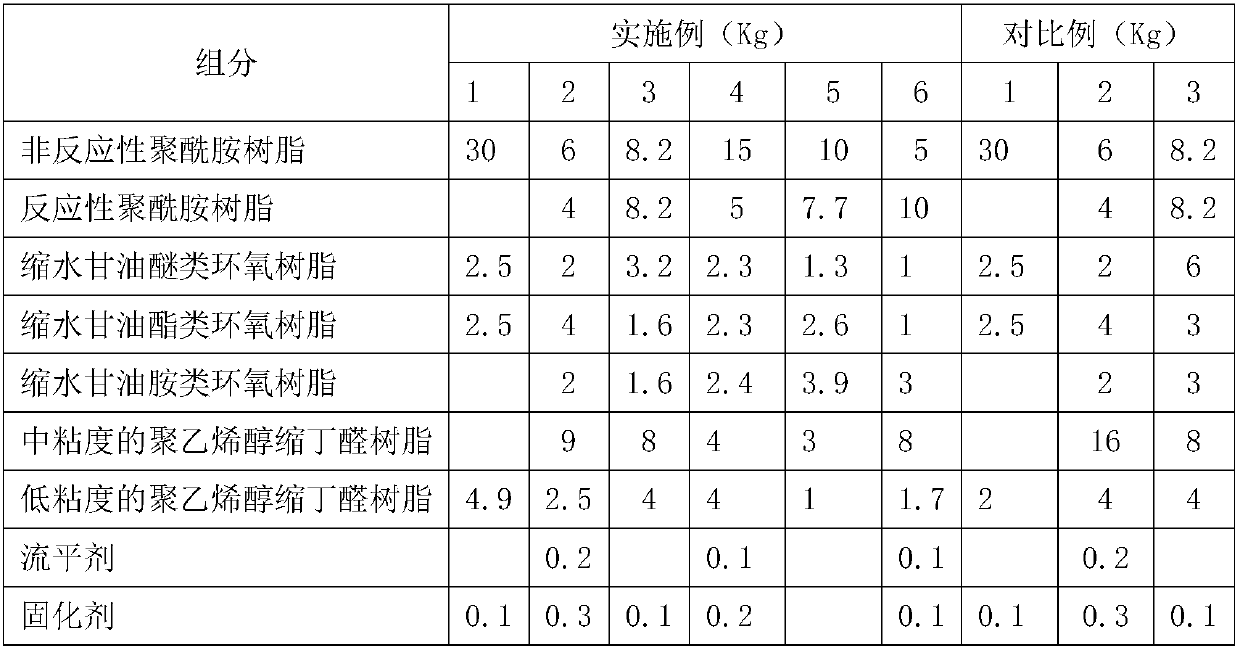

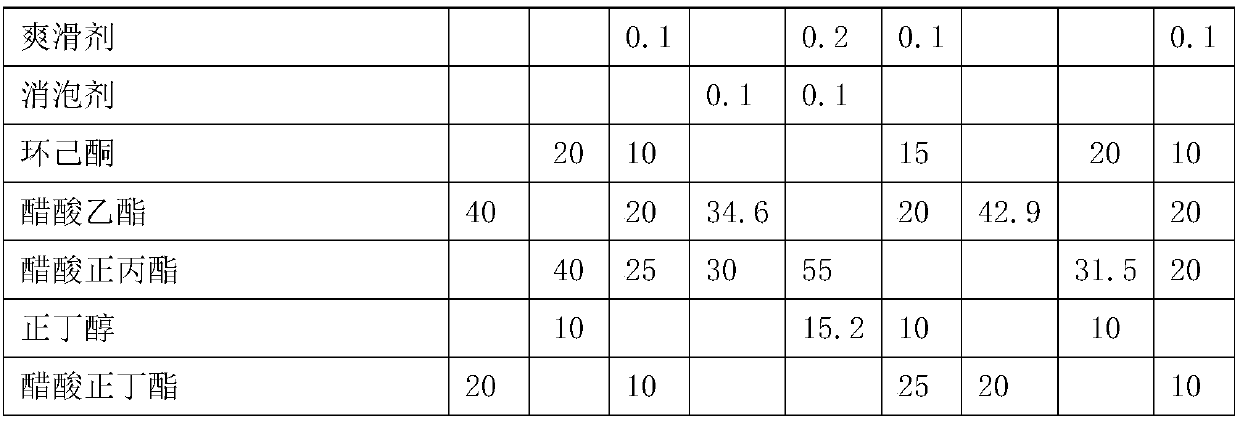

Method used

Image

Examples

Embodiment 1

[0030] The multifunctional coating composition used for polyethylene candy packaging film of the present embodiment is prepared using the raw materials of the components and contents shown in Table 1; the specific preparation includes the following process steps:

[0031] (1) 40 kilograms of ethyl acetate and 20 kilograms of n-butyl acetate are dropped into the reactor, and the temperature is raised to 60° C.;

[0032] (2) 30 kilograms of non-reactive polyamide resins, 2.5 kilograms of glycidyl ether epoxy resins, 2.5 kilograms of glycidyl ester epoxy resins, and 4.9 kilograms of low-viscosity polyvinyl butyral resins are dropped into the reactor, Stir at high speed for 4.0 hours until fully dissolved;

[0033] (3) Add 0.1 kg of curing agent into the reaction kettle and stir until it is evenly dispersed.

[0034] The paint is directly coated on the coating machine, the leveling is good, the coating surface is flat, the molding temperature is 80-95 ℃, the molding effect is goo...

Embodiment 2

[0036] The multifunctional coating composition used for polyethylene candy packaging film of the present embodiment is prepared using the raw materials of the components and contents shown in Table 1; the specific preparation includes the following process steps:

[0037] (1) 20 kilograms of cyclohexanone, 40 kilograms of n-propyl acetate, and 10 kilograms of n-butanol are dropped into the reactor, and the temperature is raised to 55° C.;

[0038] (2) 6.0 kg of non-reactive polyamide resin, 4.0 kg of reactive polyamide resin, 2.0 kg of glycidyl ether epoxy resin, 4.0 kg of glycidyl ester epoxy resin, 2.0 kg of glycidyl amine epoxy resin , 9.0 kilograms of medium-viscosity polyvinyl butyral resin, 2.5 kilograms of low-viscosity polyvinyl butyral resin are put into the reaction kettle, stirred at high speed for 2.5 hours, until fully dissolved;

[0039] (3) Add 0.2 kg of leveling agent and 0.3 kg of curing agent into the reaction kettle in turn, and stir well until the dispersio...

Embodiment 3

[0042] The multifunctional coating composition used for polyethylene candy packaging film of the present embodiment is prepared using the raw materials of the components and contents shown in Table 1; the specific preparation includes the following process steps:

[0043] (1) 10 kilograms of cyclohexanone, 20 kilograms of ethyl acetate, 25 kilograms of n-propyl acetate, and 10 kilograms of n-butyl acetate are dropped into the reactor, and the temperature is raised to 60° C.;

[0044] (2) 8.2 kg of non-reactive polyamide resin, 8.2 kg of reactive polyamide resin, 3.2 kg of glycidyl ether epoxy resin, 1.6 kg of glycidyl ester epoxy resin, 1.6 kg of glycidyl amine epoxy resin , 8.0 kilograms of medium-viscosity polyvinyl butyral resin, 4.0 kilograms of low-viscosity polyvinyl butyral resin are put into the reaction kettle, stirred at high speed for 3.0 hours, until fully dissolved;

[0045] (3) Add 0.1 kg of smoothing agent and 0.1 kg of curing agent into the reaction kettle in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com