Treatment method for high concentration organic waste liquid in sucralose production

A technology of organic waste liquid and sucralose, which is applied in biological water/sewage treatment, sedimentation treatment, water/sewage treatment, etc., can solve the problems of many reagents required for treatment, high energy consumption in the treatment process, and low combustion value of organic matter. , to meet the needs of environmental protection, simple equipment and reagents, and achieve the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, a method for treating high-concentration organic waste liquid in the production of sucralose, the steps are as follows:

[0031] (1) Place 50t of high-concentration organic waste liquid collected in a spherical concentrator for primary concentration. The concentration temperature is 85°C and the vacuum degree is -0.09MPa. After completion, 24t fraction A and 26t fraction A are obtained; fraction A is directly used for production;

[0032] (2) Place the above-mentioned distillation bottom A in a concentrator for secondary concentration. The concentration temperature is 120°C and the vacuum degree is -0.09MPa. The concentration ratio accounts for 35% of the total volume of the distillation bottom A. 5t, to obtain 9.6t fraction B and 8t distillation bottom B;

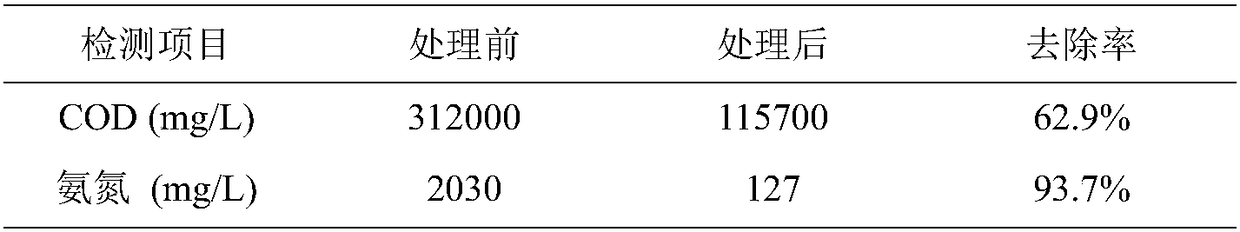

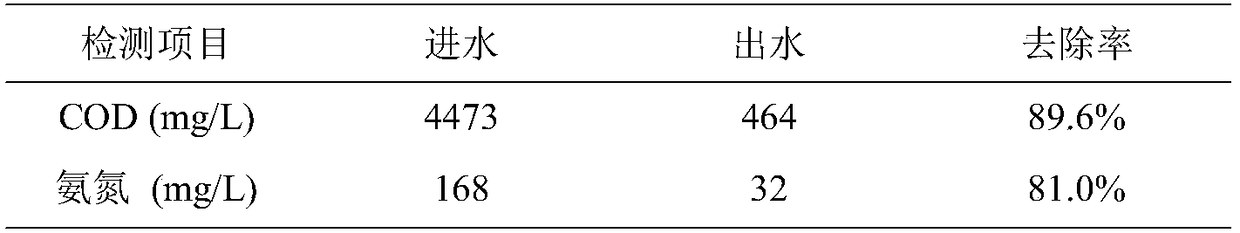

[0033] (3) Add 1.5t of sodium hydroxide three times to the above-mentioned distillation bottom B, reflux at 100°C for 3 hours, and perform three-stage concentration after completion. The concent...

Embodiment 2

[0045]In this embodiment, a method for treating high-concentration organic waste liquid in the production of sucralose, the steps are as follows:

[0046] (1) Place the collected 50t of high-concentration organic waste liquid in a horizontal concentrator for primary concentration. The concentration temperature is 90°C and the vacuum degree is -0.092MPa. The concentration ratio accounts for 45% of the total volume of the organic waste liquid. After the concentration is completed, 22.5t fraction A and 27.5t fraction A are obtained; fraction A is directly used for production;

[0047] (2) Place the above-mentioned distillation bottom A in a concentrator for secondary concentration. The concentration temperature is 130°C and the vacuum degree is -0.092MPa. The concentration ratio accounts for 40% of the total volume of the distillation bottom A. 5.1t, to obtain 11t fraction B and 8.2t distillation bottoms B;

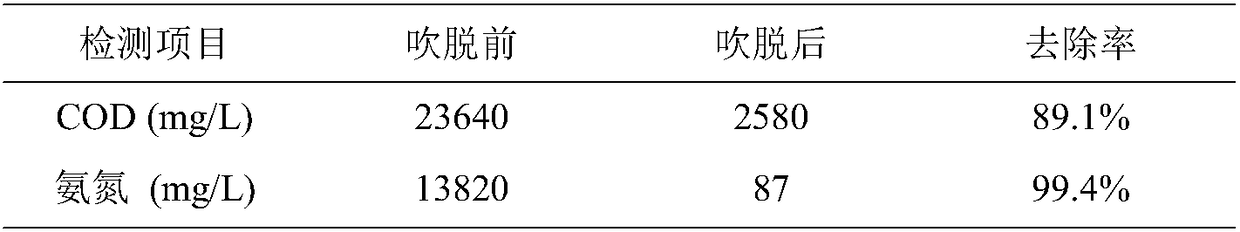

[0048] (3) Add 1.7t of potassium hydroxide three times to the above di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com