Clean water tank of centralized treatment system for industrial wastewater

A technology for centralized treatment of industrial wastewater, applied in the fields of metallurgical wastewater treatment, water/sewage treatment, special compound water treatment, etc., can solve the problems of inconvenient cleaning and maintenance, unadjustable height of the upper triangular weir, and unsatisfactory structure design of the clear water tank, etc. Achieve the effect of ideal structural design and easy daily cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

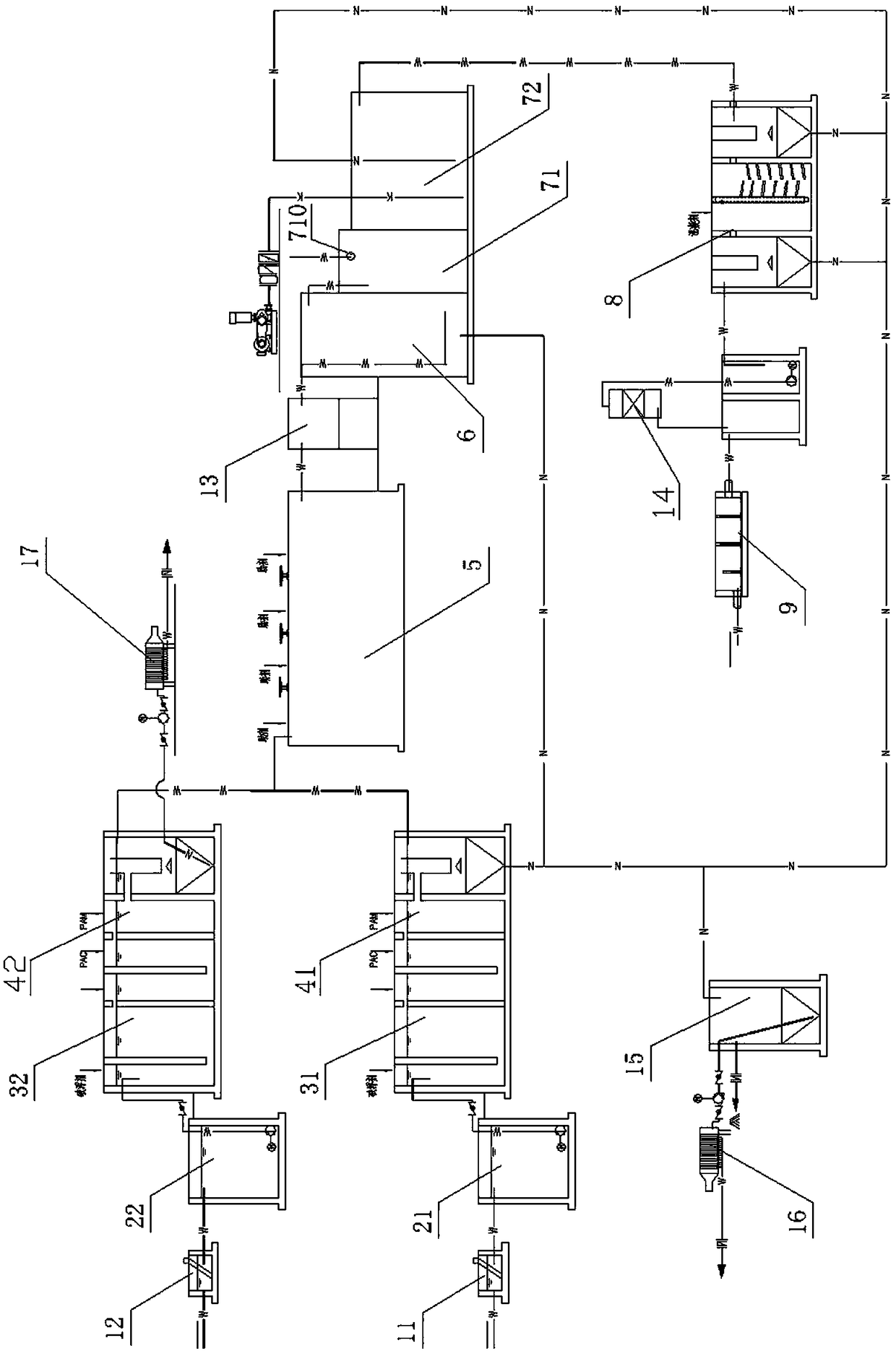

[0024] The specific embodiment of the present invention is described below with reference to accompanying drawing, remark: among the accompanying drawings, the W line represents the sewage pipeline circuit; Among the accompanying drawings, the N line represents the sludge pipeline circuit.

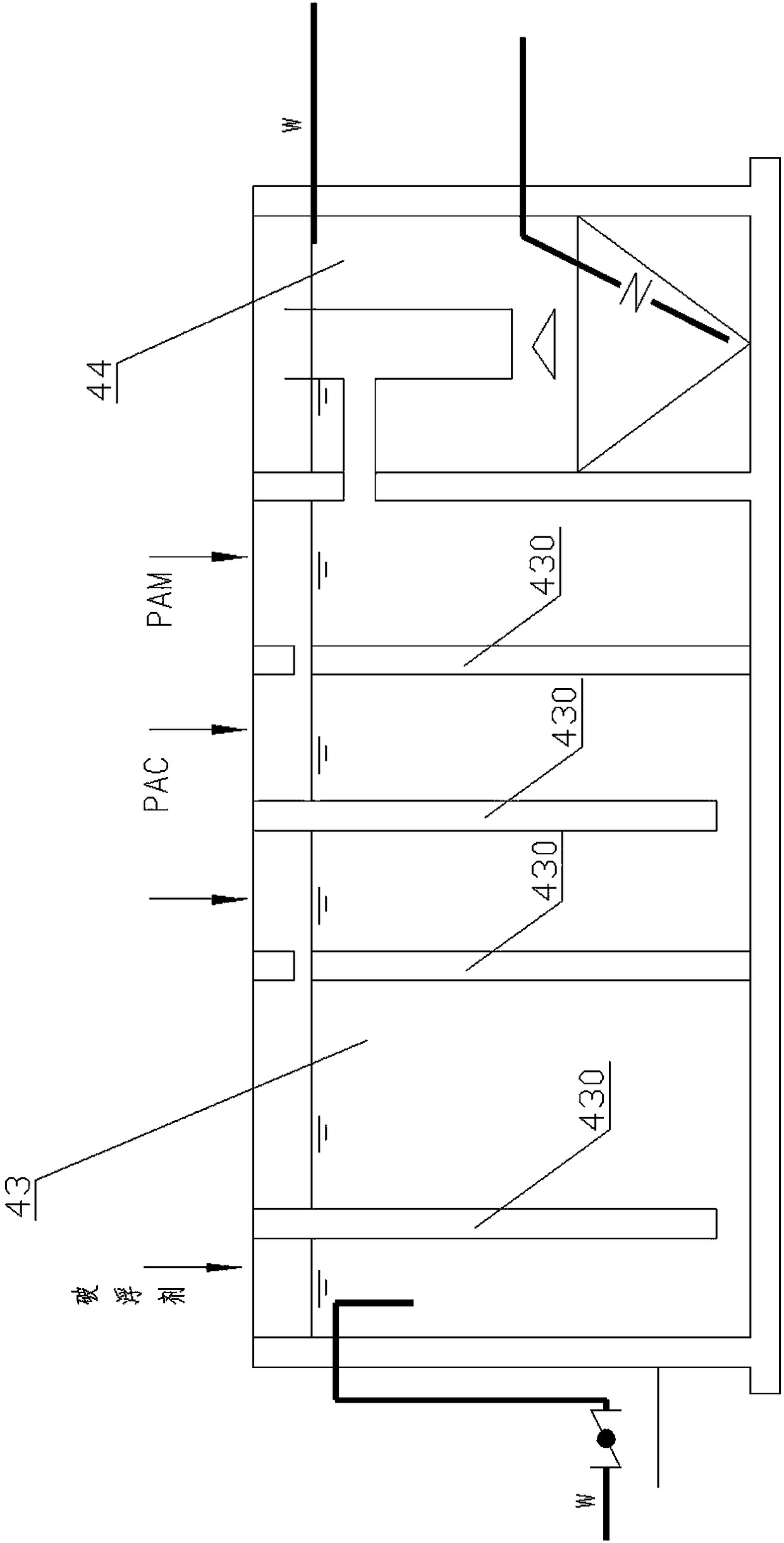

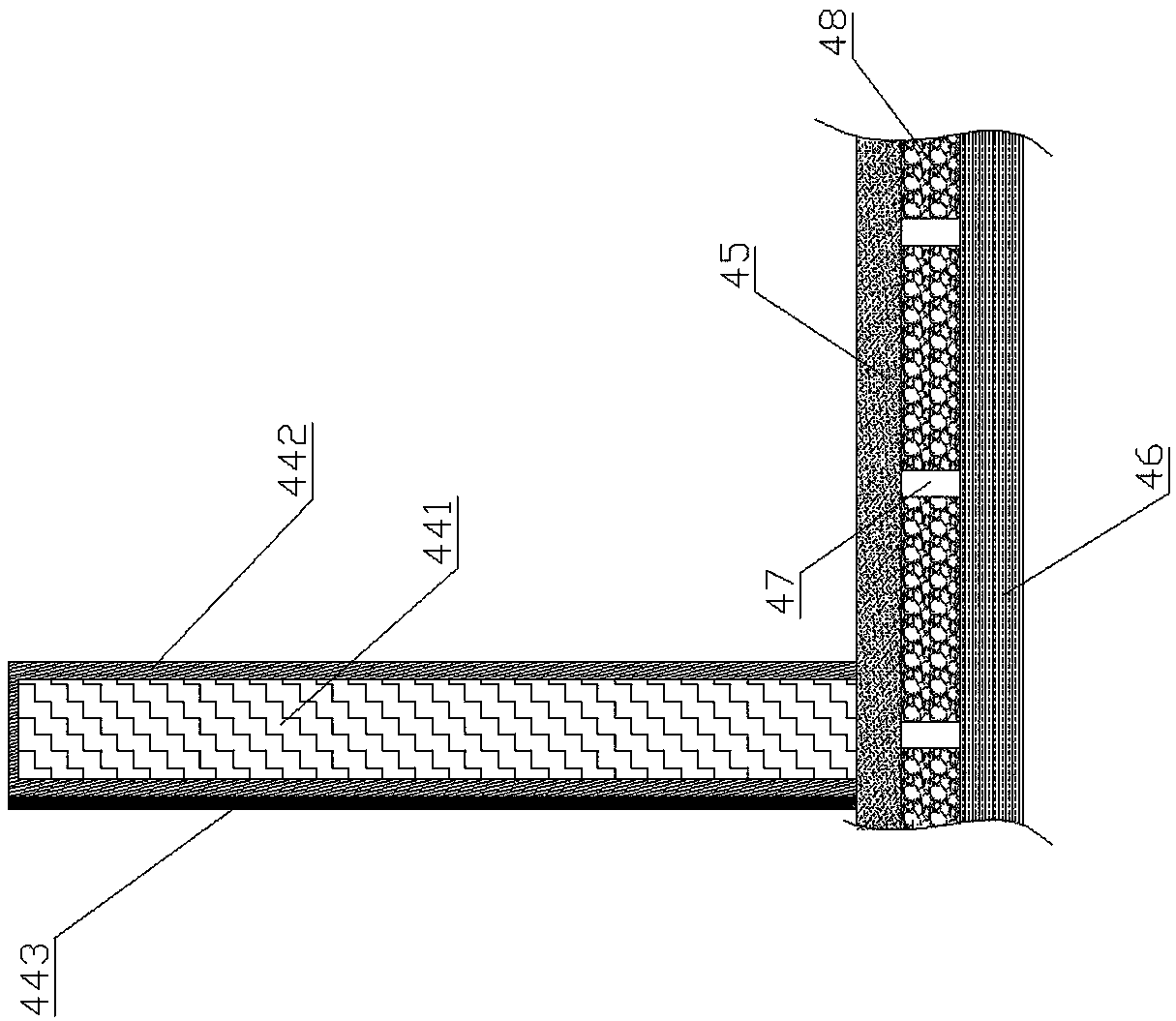

[0025] Refer to attached figure 1 . A method for centralized treatment of industrial wastewater, in which foundry wastewater is sequentially processed through coarse filtration, first regulating tank 21, first grease separation tank 31 and first coagulation reaction sedimentation tank 41 to obtain first wastewater and first sludge The chromium-containing waste water is processed by coarse filtration, the second adjustment pond 22, the second grease separation pond 32 and the second coagulation reaction sedimentation pond 42 to obtain the second waste water and the second sludge, and then the first waste water After being re-concentrated with the second wastewater, it will be treated in tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com