Reinforcing tube and manufacturing method thereof

A technology of reinforced tubes and composite tubes, applied in the directions of superstructure, superstructure sub-assembly, transportation and packaging, etc., can solve the problem of heavy weight of the reinforced structure of the side beam on the A-pillar, and achieve optimal structural design, light weight, and materials The effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

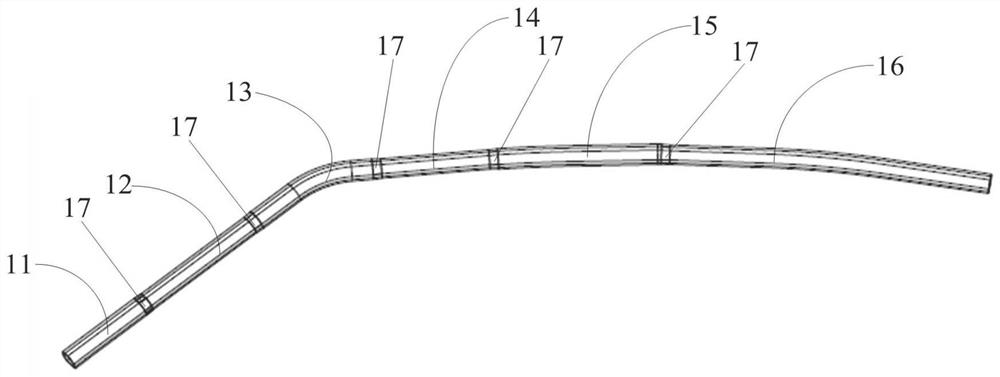

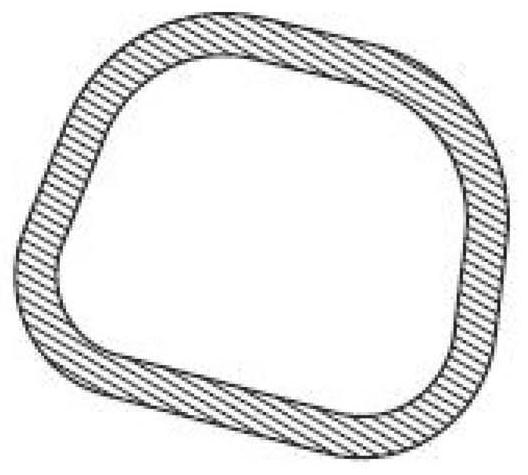

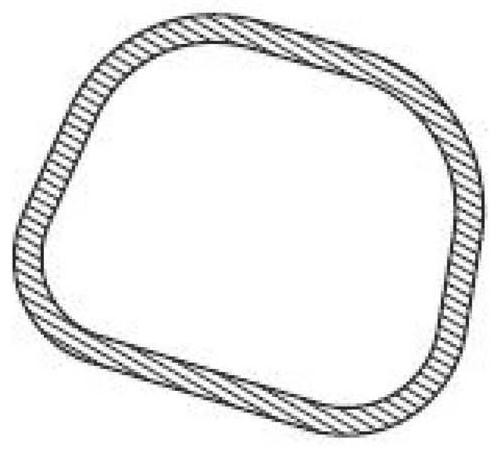

[0036] combine Figure 1 to Figure 4 As shown, the reinforced pipe proposed in Example 1 is a carbon fiber composite pipe, and the reinforced pipe includes a first section 11, a second section 12, a third section 13, a fourth section 14, a fifth section 15 and a sixth section connected in sequence 16. The thickness of the second section 12, the thickness of the fourth section 14 and the thickness of the sixth section 16 are equal, and the thickness of the first section 11, the thickness of the third section 13 and the thickness of the fifth section 15 are all greater than the thickness of the second section 12 The thickness of the reinforcement tube is used to connect the vehicle side wall outer panel and the vehicle side wall inner panel. The third segment 13 in the first embodiment is provided with a curved portion.

[0037] The reinforced pipe in this embodiment 1 is a carbon fiber composite pipe. Compared with the steel pipe in the prior art, it has higher strength and li...

Embodiment 2

[0055] combine Figure 5 As shown, this embodiment 2 provides a method for manufacturing a reinforced tube, which is used to manufacture the reinforced tube in embodiment 1. The method includes:

[0056] Step S101: determining the structural parameters of the reinforcing tube;

[0057] Step S102: adjusting the structure of the mandrel according to the structural parameters;

[0058] Step S103: Perform three-dimensional weaving on the mandrel according to the structural parameters and using carbon fibers to obtain a pre-woven piece;

[0059] Step S104: taking out the mandrel in the pre-woven part and obtaining a prefabricated body;

[0060] Step S105: placing the prefabricated body in the mold, and injecting epoxy resin into the mold;

[0061] Step S106: Perform pressurized heat preservation and curing treatment on the prefabricated body in the mold to obtain a cured tube;

[0062] Step S107: Trimming the cured tube to obtain a reinforced tube.

[0063] In Embodiment 2, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com