Dry material stirring and conveying device

A technology for conveying devices and materials, applied in cement mixing devices, selling raw material supply devices, clay preparation devices, etc., can solve problems affecting construction progress, concrete stagnation, rapid solidification, etc., to avoid material leakage and reduce the possibility of pipe plugging Sex, the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

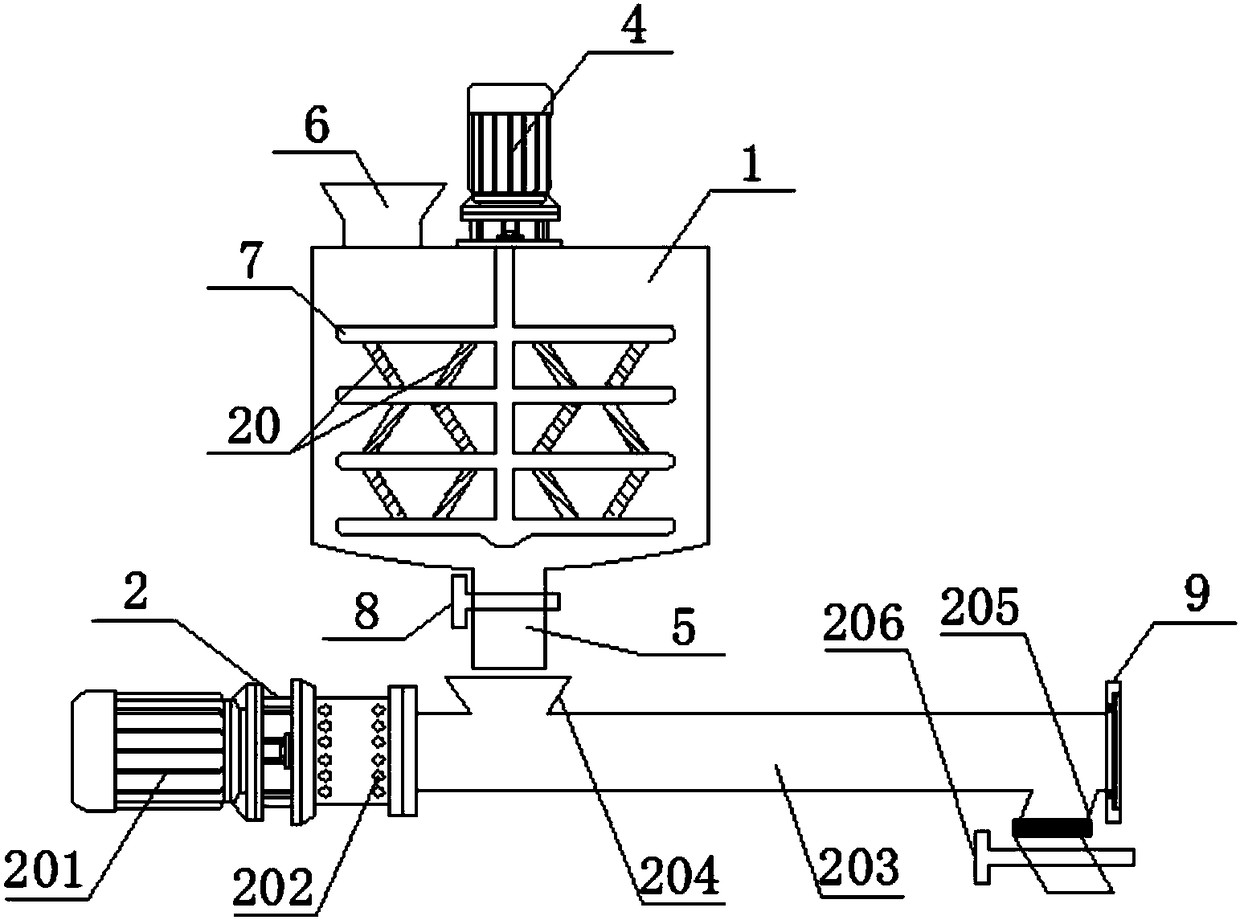

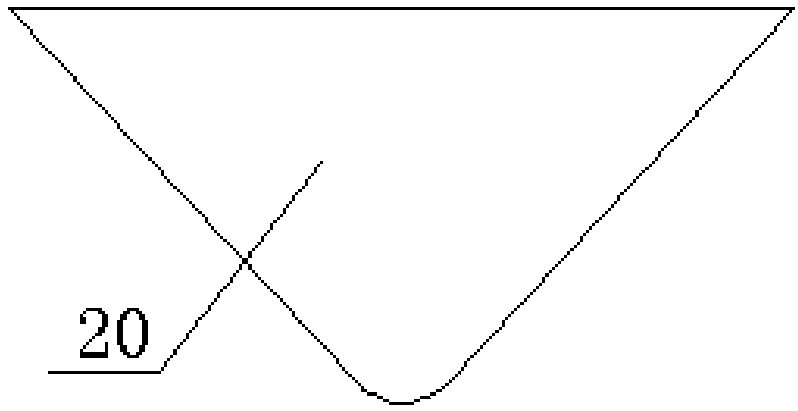

[0021] Embodiment 1: refer to Figure 1-3 , a dry material mixing and conveying device, including a first material cylinder 1 and a screw conveying mechanism 2, the bottom of the first material cylinder 1 is provided with a screw conveying structure 2, and the screw conveying mechanism 2 includes a second drive motor 201, a speed reducer 202 and a feeding pipe 203, a speed reducer 202 is arranged between the second drive motor 201 and the feeding pipe 203, a feeding screw is arranged inside the feeding pipe 203, and a feeding screw is arranged inside the feeding pipe 203 The top is provided with a material receiving port 204 and the bottom is provided with a second blanking port 205. The top of the first barrel 1 is provided with a first drive motor 4 and the bottom is provided with a first blanking port 5. The first drive One side of the motor 4 is provided with a hopper 6, and the end of the output shaft of the first driving motor 4 is connected with a stirring rod 7, and th...

Embodiment 2

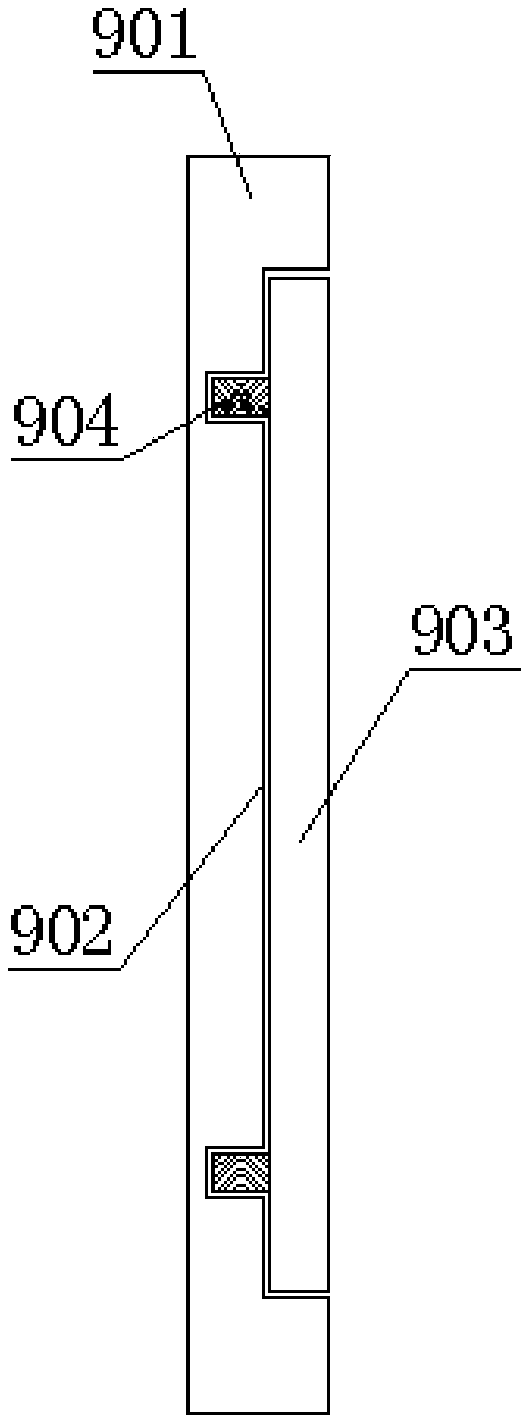

[0022] Example 2: Refer to Figure 2-7 , applying the present invention to a concrete conveying device, comprising a first material cylinder 1, a screw conveying mechanism 2 and a second material cylinder 3, the top of the first material cylinder 1 is provided with a screw conveying structure 2, and the screw conveying mechanism 2 The feeding mechanism 2 includes a second driving motor 201, a speed reducer 202 and a feeding pipe 203, a speed reducer 202 is arranged between the second driving motor 201 and the feeding pipe 203, and a feeding pipe 203 is provided inside the feeding pipe 203. Material screw, the top of the feeding pipe 203 is provided with a material receiving port 204 and the bottom is provided with a second blanking port 205, the bottom of the screw feeding mechanism 2 is connected with a second barrel 3, and the screw feeding mechanism 2 It communicates with the second barrel 3 through the second blanking port 205, the top of the first barrel 1 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com